The Secret Ingredient for Long Term VFFS Machine Reliability

For most of us, when we decide to make a purchase, the interaction with the team that designed and produced it is short-lived. When we go to buy...

4 min read

Emily Brogan

:

Updated on December 13, 2023

Emily Brogan

:

Updated on December 13, 2023

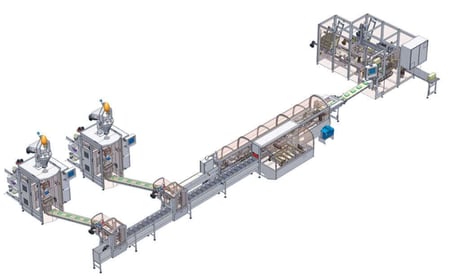

There are many good reasons why companies might add vertical bagging machinery to their operation. In addition to adding capacity to meet growing demand and new customer requirements, other reasons we frequently hear include:

Each of the above motivations often carry measurable cost reduction or sales growth potential, and we're happy to help buying teams perform a realistic analysis of the total cost to implement, the lifetime cost to own/operate, and the return on those investments based on the agreed, anticipated savings or revenue growth.

They often discover the growth and/or savings are larger than originally assumed, once they conduct thorough technical and market audits.

We believe that these calculations need to be as carefully engineered as the system itself. Check out PMMI's ProSource article that details many of the intricacies necessary to planning a successful form/fill/seal project.

But what's often overlooked is the need to take into account various factors just as how machine designs should consider future potential requirements and corporate strategy.

We often see a lot of very cursory "ROI justifications" floating around the market, however, which often overlook very real costs related to machine projects. That's a potentially expensive oversight, so we've pulled together a list of other costs that we recommend you include in your cost/return planning. In addition to the machine itself, crating, freight, training, and commissioning, these include:

Let's look at each in more detail.

Whether you're changing from expensive pre-made pouches to roll stock, or even from an older web width and register length to narrow and shorten the package to reduce material usage, even carefully orchestrated, it's going to be very difficult to avoid some inventory obsolescence.

You'll have wasted material and disposal costs for the obsolete inventory.

Of course, you'll also have new artwork charges, plate costs, and more. Not to mention the time spent as cross-functional teams review proofs, maybe even attend press proofs, create new inventory items in your ERP system, etc.

Keep in mind, though, that these can be great opportunities to update branding and improve package aesthetics and function.

It's unlikely that any machine will fit perfectly in an empty space in your current factory layout. Often, things will have to be moved and adjusted for product and finished goods movement, employee access, mechanicals (compressed air, electrical, vacuum, water), etc. Of course, that's a good thing if setting up a more efficient floor space layout to make room for added capacity was the goal. Regardless, there are a few considerations to be aware of.

Initially, you may have to make adjustments to move the old machine out (if there's a replacement) and the new machine in. Mezzanine heights often require adjustment for different combination scale/bagger stackups, particularly if discharge heights are being changed for automated end-of-line shelf-ready packaging.

Those changes require planning, project management, engineering hours, and rigging and mechanical contractor costs. Project management involves planning for routine maintenance disruptions and overtime for internal resources.

You may also require engineering support to evaluate whether changes require re-permitting for dust control, noise abatement, explosive prevention, or other health and safety regulations. And if permit modifications/approvals are required, there is a potential project cost associated with those modifications.

The good news regarding VFFS machines is that they often require less floor space than the equipment they replace, can be engineered to fit into existing height limitations, include design features to control dust, and run with limited air and electrical requirements.

This process will disrupt production. That means proactively planning for the disruption, any necessary overtime, increased finished goods inventory space, and packaging material to build up a buffer to accommodate the disruption.

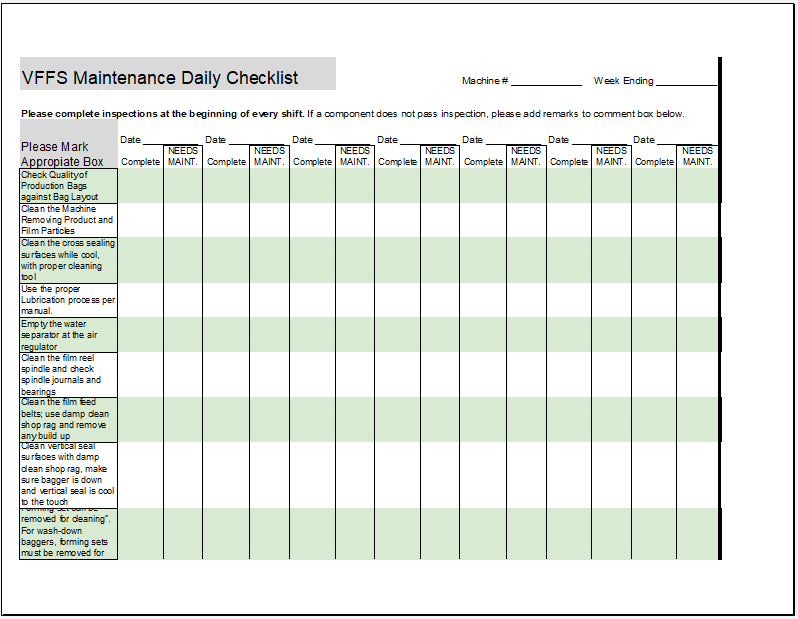

There will also be operator training (planning on three shifts with overlap) and maintenance training which will typically result in overtime costs as well.

There can be great value, though, in controlled events which give the team opportunities to respond and plan for disruption.

Package changes will require work and training with the marketing/brand and sales teams. Often there are testing and pilot requirements, along with pre-sales, promotional costs, customer presentations, and more. There may be marketing initiatives to introduce new packages and potential merchandising considerations such as planogram and slotting changes.

And these can be great opportunities to get retailers and customers on board, earning loyalty for your efforts to deliver on their expectations and desires.

A new machine will often require new change parts. Forming sets can represent a significant investment depending on how many bag styles and package sizes you produce. You'll also have some cost for replacement parts and wear items - whether this is embedded in the machine cost as a "spare parts kit" or separate, it's a real cost.

Further, you'll likely have a new set of PM requirements to track and equipment to maintain maintenance team familiarity with - plus a new vendor to build relationships with, and items to create in your MRO ordering and inventory system.

Don't lose sight of the often significant improvements in OEE and reduction in downtime, break/fix, and parts obsolescence that are achieved through replacing aging equipment.

These costs, hassles, and resource requirements are real. In our experience, it's better to be open with colleagues on your buying team because they may be significant impediments for other departments and functions, and failure to acknowledge and address the issues might result in your project being bumped from the short list to the not list.

When you really dig into all the moving pieces, the project that sounds so simple as a typical sales rep discusses it, turns out to be a more significant business undertaking. When we all have too much on our plates, that merits careful consideration. But it's important not to let a realistic overview lead to discouragement and inaction.

There's a reason the project originally was under consideration, and there were market opportunities to seize and/or savings to capture. Those haven't changed. Your project still probably makes sense, but with this insight, the process will be smoother.

If you want a reality check regarding what a VFFS could do for your operation, and what would really be involved in getting there, Rovema has experienced engineers that can provide insights from thousands of products, applications, and installations.

For most of us, when we decide to make a purchase, the interaction with the team that designed and produced it is short-lived. When we go to buy...

A wise man once said, “An ounce of prevention is worth a pound of cure.” That wise man was none other than the founding father, Benjamin Franklin. In...

If you're hands-on with packaging machinery, you likely spend a lot of time making sure your packaging machinery stays up and running, changing wear...