Packaging Automation Solutions to Address The Grocery E-Commerce Surge

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

Rovema has over 20 years of experience packaging nuts and dried fruit. These can be packed into simple pillow bags or fancy stand-up bags with special features. The solution can be a stand-alone bagging machine or a complete automatic packaging line.

When it comes to fancy bags, the Stabilo® bag developed by Rovema in 1991 is an industry-standard. Specific options include a true-offset seal which yields full panels on all 4 sides of the bag. Excellent for graphics. The true offset seal also aids in bag stand-up since it reduces the multiple layers in the bottom seal of a center back seal which can be troublesome in achieving a stand-up bag for smaller lightweight bags.

Factors to consider include breakage, fines, stickiness, bag opening size

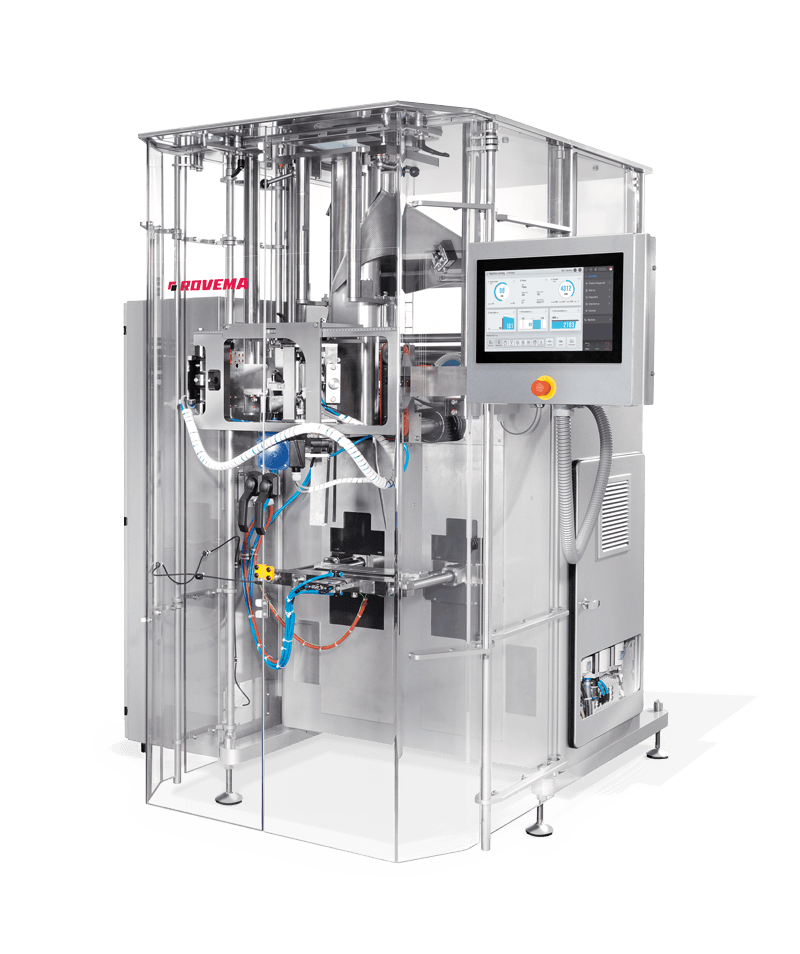

The new BVC series bag-making technology provides advanced features that increase the performance and efficiency of automatic dried fruit and nut packaging. The BVC is a 2-axis servo-driven machine capable of operating at speeds over 240/min. Springs have been eliminated from the jaws meaning precise control over jaw position. This means excellent product in jaw detection even at the highest of rates which reduces product in seal and other quality control issues. Another feature of the BVC is Premium Seal ® which provides variable pressure over the course of one bag-making cycle. This results in better performance in handling fragile films and overall better seal performance for challenging film structures. The BVC also is the first bag maker to use servo gusseting which gives much higher performance when creating gusseted bags, especially at higher speeds and with lighter gauge films. Refer to separate information here [link] for complete details on the BVC.

We run tube nuts which are particularly difficult due to the small bag opening. Over the past 5 years, we have developed technology that has resulted in output increases of over 40%.

Dosing can be accomplished with a weigher or cup doser. The former gives greater accuracy and the latter for greater speed. The right solution is determined by evaluating output versus giveaway cost.

With either dosing solution, Rovema provides a turnkey solution. We can offer direct mount weighers requiring no mezzanine (reduced clutter and better hygiene) and one common control panel for both weighers and bag makers.

For cup dosing solutions, Rovema is the manufacturer of both doser and bag maker providing a single source solution again integrated with direct mount and common (one) control panel interface.

Gas flushing is also a consideration where residual oxygen level is the primary factor.

Opening and reclosure is a consideration. Bags can be produced with a simple tear notch for ease of opening. Zipper is common. There are various types including a velcro type. Other reclosures include tin-tie (less common), and tape (dust is a concern).

ROVEMA’s equipment offers an unmatched ROI and exceptional levels of OEE. These are achieved by our German-engineered build quality and resulting machine performance. Our experience and engineering ensure proper execution of machines, common manufacture, and workforce for your application. Our sales team will be ready to assist you in finding your ideal packaging solution for your nuts and dried fruit products.

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

Sustainable packaging materials are becoming increasingly popular, and many of today’s CPG brand teams and other...

Editors Note: This blog was originally published in October of 2017 but has been edited and republished with additional...