Packaging Automation Solutions to Address The Grocery E-Commerce Surge

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

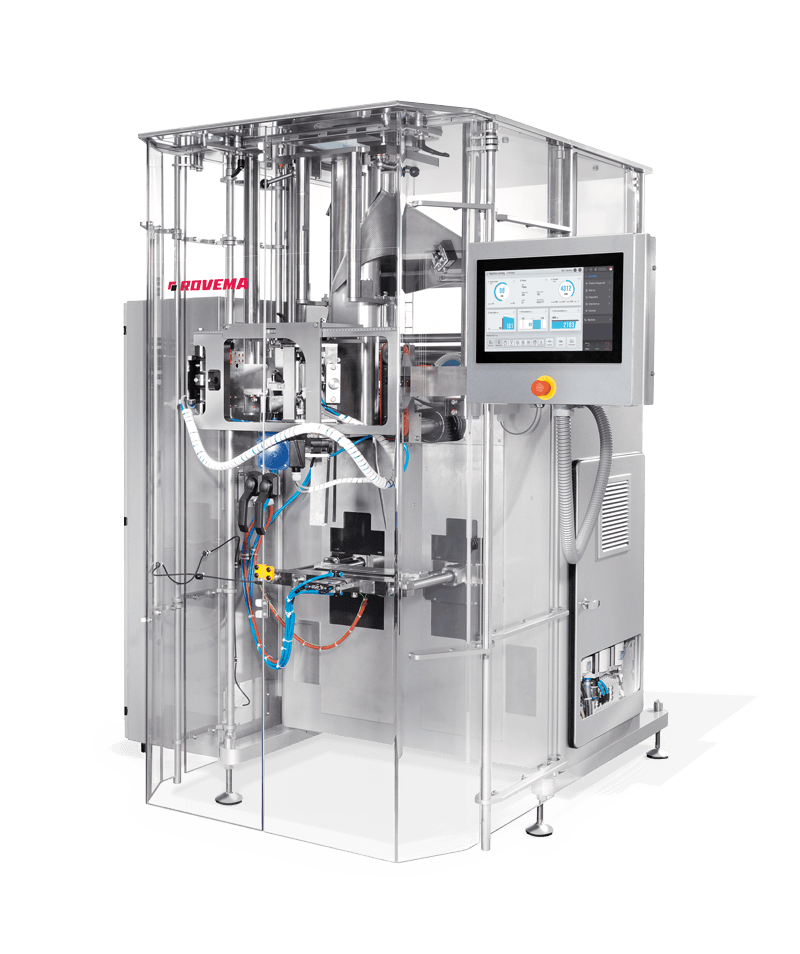

With over 50 years of experience in candy packaging, Rovema is at the forefront of innovation in the industry. We offer a variety of packaging options for your candy products, including high-speed pillow bags and high-quality stand-up bags with special features. Whether you need a stand-alone bagging machine or a complete automatic packaging line, we have the perfect solution for you.

When it comes to sophisticated bag styles, the Stabilo® bag, developed by Rovema in 1991 is the industry standard. Specific options include a true-offset seal which yields full panels on all 4 sides of the bag. Excellent for graphics. The true offset seal also aids in bag stand-up since it reduces the multiple layers in the bottom seal of a center back seal which can be troublesome in achieving a stand-up bag for smaller lightweight bags.

Other special bag styles include the Ropack (Doypack), and Flexcan.

There are crucial factors to take into account when it comes to confectionery packaging. Beyond the obvious considerations of potential product damage, fines, stickiness, bag opening size, and re-closure, there are even more aspects that demand attention.

Your packaging should contribute to the aesthetic appeal of your product, ensuring that it not only protects the product but also enhances its visual appeal. It's your product's first impression, of course!

Additionally, the packaging needs to be user-friendly, making your product accessible while maintaining freshness. The right packaging solution will take these considerations to the next level, providing advanced features that guarantee optimal performance and efficiency in the automatic candy packaging process.

Machine versatility is key with a Rovema solution. This results in producing various bag styles on the same machine with efficient and repeatable changeover.

The SBS machine solution takes bag making to another level by delivering low fill drop heights, extreme flat bottom bags, and additional bag features such as tin tie, gather + clip, fold over and tape over 30 such bag top styles available.

Dosing is primarily accomplished with weigher or cup doser. The former generally gives greater accuracy and the latter greater speed. The right solution is determined by evaluating output versus giveaway cost along with the other considerations mentioned above.

With either dosing solution Rovema provides turnkey solution. We can offer direct mount weighers requiring no mezzanine (reduced clutter and better hygiene) and one common control panel for both weigher and bag maker.

For cup dosing solution, Rovema is the manufacter of both doser and bag maker providing a single source solution again integrated with direct mount and common (one) control panel interface.Opening and reclosuer is a consideration. Bags can be produced with a simple tear notch for ease of opening. Zipper is common. There are various types including a velcro type. Other reclosures include tin-tie (less common), tape (dust is a concern).

In addition to dosing and bag making, Rovema manufactures secondary automatic packaging machinery. We often deliver complete automatic turnkey packaging lines for dosing, bag making, coding, inspection, cartoning and casing. The turnkey solution is engineered and built in one facility with a common workforce. This minimizes complication and risk for the tunkey solution.

%20-%20v1.jpg?width=1426&height=901&name=RVS-ALL-213%20-%20Messestand%20Fachpack%20-%20Wand%20B%2BG%20(356x348mm%20-%201zu10)%20-%20v1.jpg)

ROVEMA’s equipment offers an unmatched ROI and exceptional levels of OEE. These are achieved by our German-engineered build quality and resulting machine performance. Our experience and engineering ensure proper execution of machines, common manufacture, and workforce for your application.

Our team of VFFS experts will be ready to assist you in finding your ideal packaging solution for your confectionery products.

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

A Quick Recap: the Rovema Brown Bag Blog Series If you’ve been following along with this series for the past few...

It's no secret that candy and snacks are a popular and sought-after product line. So much so, that the industry is...