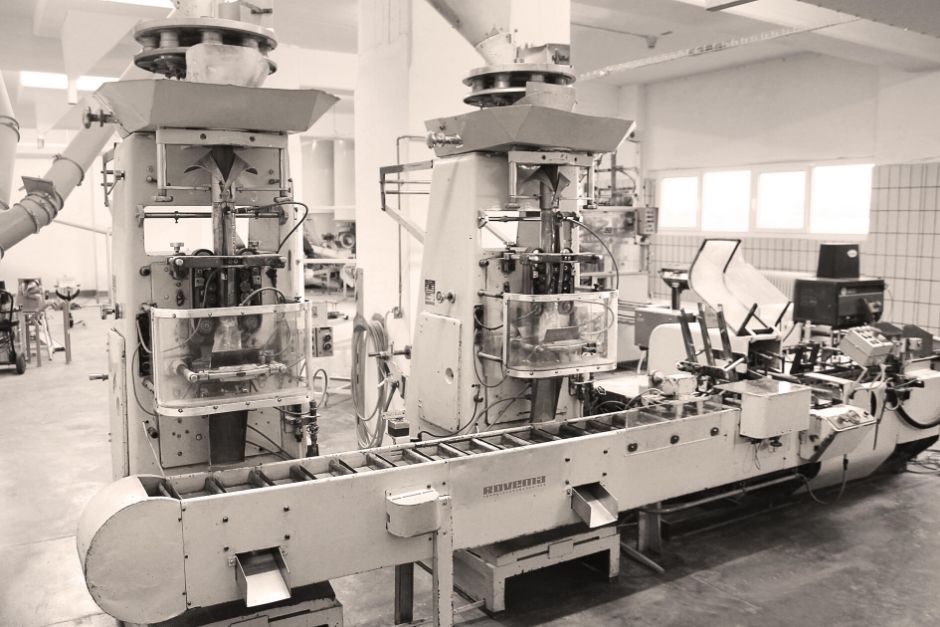

“Old Red” - The VFFS Machine That Made You Millions

So You Have a Reliable...but Aging Vertical Form Fill and Seal Machine. Does your production team have nicknames for vertical form/fill/seal machines...

5 min read

Emily Brogan

:

Updated on January 3, 2023

Emily Brogan

:

Updated on January 3, 2023

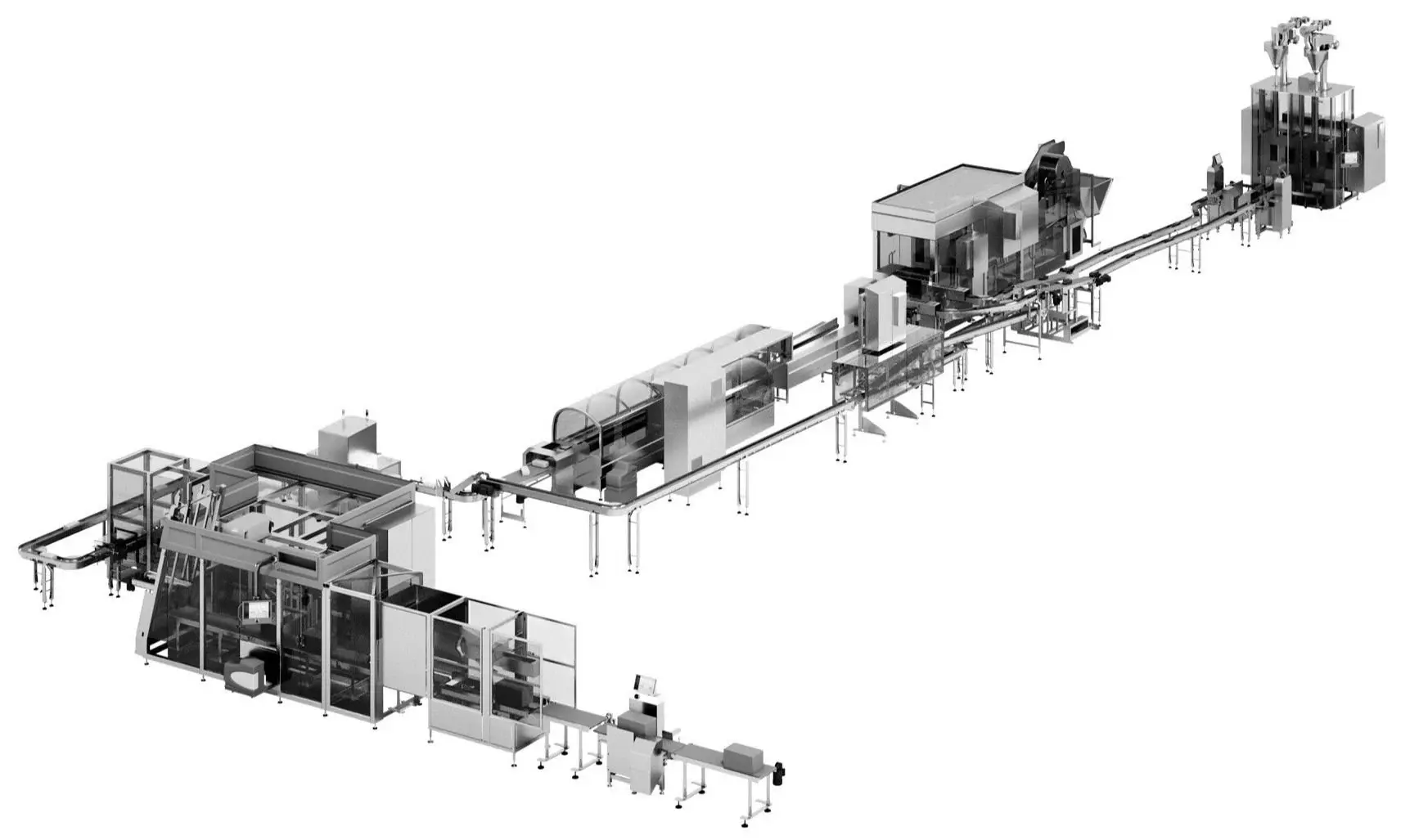

If you're hands-on with packaging machinery, you likely spend a lot of time making sure your packaging machinery stays up and running, changing wear items at regular intervals and keeping the machine clean and in the right conditions. But inevitably, no matter how much care you take with your packaging machinery, there are other non-wear components that will eventually wear out and need to be replaced at some point during the life of your bagger.

If one of those components is critical to the proper operation of your equipment, prolonged downtime can occur as you wait for it to be shipped in from the manufacturer and installed. Even if you can have a part by the next morning, that downtime still costs your company a lot of hard-earned money - often tens of thousands of dollars.

It’s impossible to foresee every component failure, but some of these components are a small investment by comparison and sometimes there are even some warning signs you can watch out for that will help you anticipate some of them and minimize their impact on your business. This article will walk you through the items we recommend keeping handy, any warning signs that you might experience, and give you general info on their importance if you don't already know so that you can make the best decision for your business on which ones might be worth keeping an extra on hand.

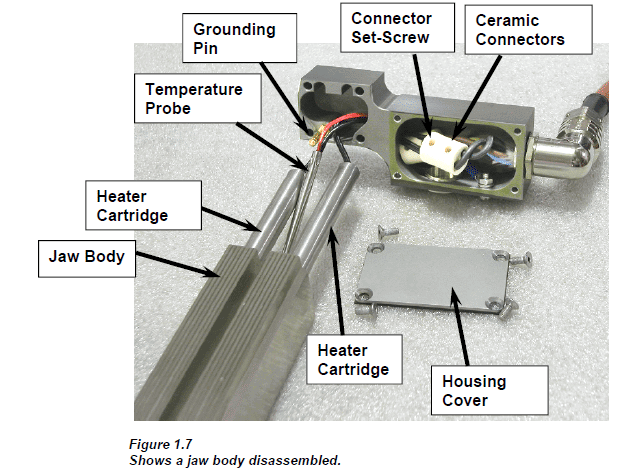

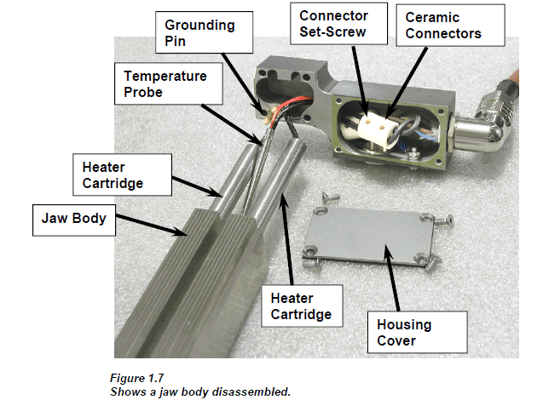

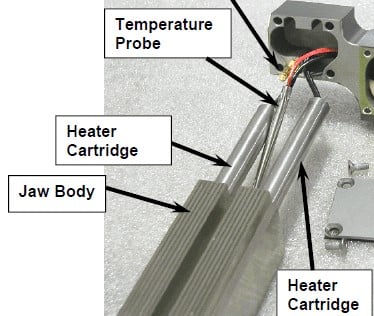

VFFS seal jaw heaters are one of the most critical components of your machine. So much so, that while they aren't considered a "wear item" and very rarely need replacing, a backup is always included in the tool kit that comes with new machines.

Weak seals are the main symptom of issues with your heater. With the way that these components are wired in parallel, you have an upper and lower heater on the front horizontal seal jaw, both monitored by a temperature probe and supplied with power. If one heater goes out, your machine may continue running without throwing a fault, but the seal quality will be diminished.

As far as lead times for ROVEMA heaters specifically, these components are always kept in stock at the Atlanta location for quick turnaround, but again, backups are supplied in the toolkit and are recommended to be kept on hand.

The heater temperature probes are needed to monitor the heat of multiple components, the vertical and horizontal sealing components, and even other areas as needed, like a button valve applicator on the back of a VFFS machine.

You'll likely have a fault come up on the HMI that states that the resistance on the temperature probes has a broken lead. These components don't give off warning signs like many aging parts, and once it has failed, voltage is no longer supplied to the heaters. Temperature probes are critical to your operation, which is why backups are initially supplied with new ROVEMA machines and why it is recommended that you always keep them on hand. They are kept in stock at our facility in Atlanta and can be sent quickly in emergent situations, but for the price, it's worth the downtime avoidance.

Heater cables are the components that supply power to the temperature probes and to the heaters themselves, going from the jaws to the front of the machine. We felt that it was important to list this component as we have gotten calls from customers that have replaced a heater on their machine but are still getting sporadic readings on their display. One end of these cables travels with the jaws as they cycle, so depending on how it has been set up, the inside wire of the cable can break, especially if the cable is too long or not anchored correctly and swings as the jaws cycle.

A broken VFFS heater cable will either intermittently short out or completely fail to provide power to the heaters and the probes. The initial symptoms will be similar to the ones pointing to heater or probe issues but if after troubleshooting, these don't seem to be the true issue, most often a heater cable issue is the root of the problem.

Depending on where the break is, sometimes it's feasible to shorten the cable and remove the compromised end, but extra heater cable is very inexpensive and valuable to have.

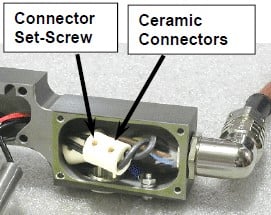

Ceramic connectors are what we would consider "nice to have" components that live inside of the terminal housing at the end of every jaw body on your VFFS machine. This part allows you to connect the wires from the heater to the heater cable. As the name suggests, it's made of ceramic and has two extremely tiny screws.

Ceramic is a tricky material, as it is heat resistant and non-conductive but is also relatively easy to damage and the screws can be easily dropped and lost. This situation is a pain to deal with if you are trying to use electrical tape to securely connect these wires to get back up and running if you don't have any extras.

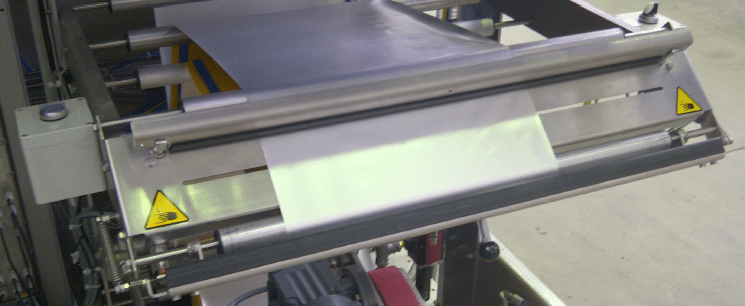

There are several important components of your ROVEMA VFFS machine that are driven pneumatically, from solenoids, cylinders, the cutting knife, and even your vertical seals moving in and out, thus needing air hoses. As the machine runs, especially with the heat and product that these air hoses are subjected to, the material can begin to degrade.

The symptoms of failure will be obvious in this case as the air hoses will be brittle when compared to new hoses or might even come loose if you happen to grab on to them when going through maintenance tasks. Eventually, the hose will become so brittle that it splits or breaks completely, causing unplanned downtime. This situation is not fun as you're either trying to patch it together with duct tape, or a team member is making a run to the hardware store where many folks will find that the hose isn't sold in metric size increments.

Like heater cables, keeping a few meters of extra hose (which most often isn't even $10 per meter) in stock if your find a hose is starting to degrade or does happen to break, getting it quickly switched out can be a low time investment.

Prox switches are used to monitor several other components of your VFFS machine, from the vertical seal bands to the film roll. For example, if the vertical seal band breaks, the "vertical seal prox" sends a signal to the HMI to halt the bagger and to signal that the seal band has broken.

As far as symptoms are concerned, for prox switches, they are either functioning or they are out. If the vertical seal prox is not working properly it will either not let the machine start-up or fails to halt the machine after a part failure, often resulting in running un-saleable packages. Another example is when the film roll is about to run out, an "out of film prox" will stop the bagger prior to the end of the film cycling all the way through, causing you to have to thread a new roll of film through the bagger.

The out of film proximity sensor switches and vertical seal proximity sensor switches are what we would consider to be the most important ones to keep on hand, as their function goes a long way to prevent headaches in your operation, but backups of many others, like the "low film prox" that can help signal your team of when to get a new roll ready to spice can be extremely helpful to have on hand as well.

The Life Cycle Services side of our business spends a lot of time thinking about and talking about maximizing your OEE and maintaining a high level of performance on your baggers throughout the time that you own it.

While unplanned downtime happens, it's not the norm. It's the day-to-day practices of preventative maintenance and changeover repeatability that go a long way towards minimizing the risk of unplanned downtime occurring and also maintaining high performance. We see these recommendations of the types of "just in case" items similarly. A small investment, sometimes a $10 part, that minimizes a large exposure that could cost your business tens of thousands of dollars.

We hope that this article was successful in helping you to build a shortlist of items to check that are stocked in your ROVEMA toolkit or in your parts crib. Another resource you mind find helpful in your day-to-day is this Preventable Maintenance checklist broken out by daily, weekly and monthly tasks that can be customized as you see fit. You can download it for free here and feel free to reach out to us in the help box if you'd like to walk through it with a VFFS expert.

So You Have a Reliable...but Aging Vertical Form Fill and Seal Machine. Does your production team have nicknames for vertical form/fill/seal machines...

Why Multi-Vendor Packaging Line Integration Creates Costly Support Bottlenecks Picture this scenario: It's week three of your new packaging line...

Overall equipment effectiveness (OEE) is a game of inches. With the uptime of machinery having a direct impact on your bottom line, it's always an...