End of Line Packaging

First Priority: Bag Management

Flexible bags and pouches require different handling during the case packing process than products in rigid packaging like bottles, cans, cartons and jars.

Gentle handling while distributing contents is critical.

This involves control of the payload and trajectory while taking into consideration weight, motion and irregularity. Sharp bag corners must be taken into consideration otherwise bags can be punctured during loading and or shipping.

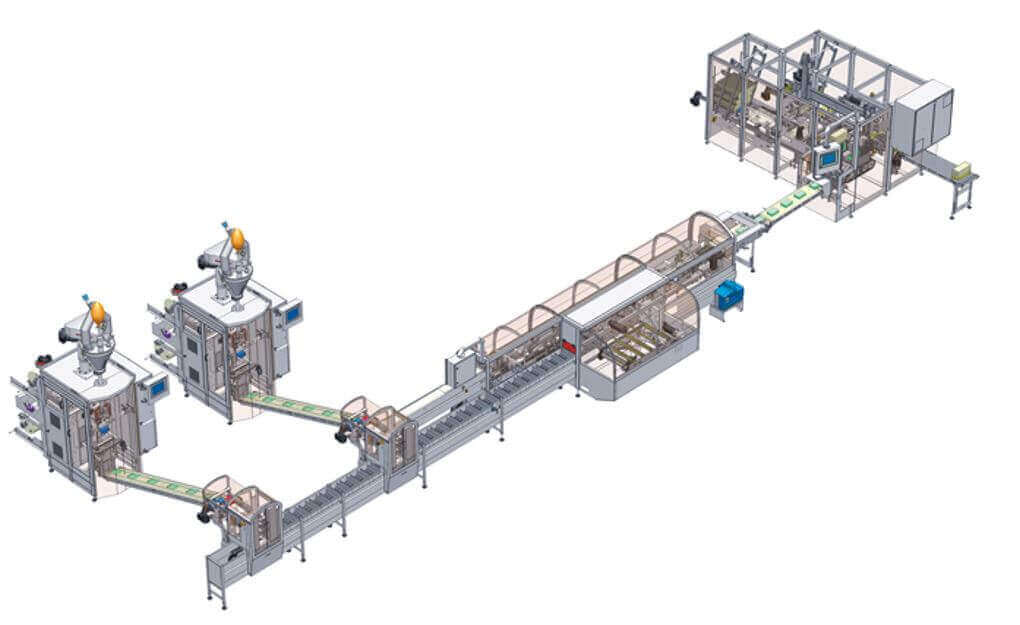

Secondary & Tertiary Packaging To Complete Your CPG Production Line

Many of our customers rely on our baggers at the heart of their production. Their product may require a combination scale rather than one of our easily integrated filling solutions, and often they pack off manually at the end of the line.

But our expertise extends beyond the take away conveyor.

In high efficiency and high volume packaging scenarios, a comprehensive and integrated end-of-line solution becomes crucial. Rovema provides a wide range of machines for cartoning, case erecting, tray packing, lidding, and case packing.

As a true single source supplier, all of these machines are designed, built, and run-out under the same roof by our company. This offers peace of mind to engineers, maintenance teams, supply chain, and procurement teams, as they can purchase packaging systems without the added complexity of integration or potential finger-pointing, even among different divisions of the same global brand.

One of the most challenging aspects often encountered is the transfer, handling, and accumulation of products. We take pride in taking care of all those minute details that are often overlooked when using external integration or when lines are assembled over time from various manufacturers.

If a true single-source, German-engineered packaging line might be the right solution for your business, check out our various options.

We Can Help you Find the Right Machine for Your Product

Cartoning, Picking, Erecting, & Packing Machines

A perfectly and fully automated end-of-line solution for your products will add a tremendous return to your products. That being said, rarely are packing, picking, or cartoning solutions "one size fits all".

Sourcing packaging solutions from the same engineers, under the same roof, as the ones that designed the rest of your line ensures the fully integrated and intricately customized solution you're promised comes to fruition without any surprises.

Maximizing Operational Equipment Effectiveness for Vertical Bagging Operations

It's a critically important topic across manufacturing industries - and it's one that we're committed to fostering dialog around.

As an organization, we stand behind our "no end of life" principle.

We also reject the industry mindset that after over the decades of running your machinery that it's expected that you'll see an incremental drop in speed and quality.

This is unacceptable to us so if you're experiencing any drop in efficiency, know that for our customers, we're committed to restoring it.

Download this guide based on our methodical efficiency audit process.

-card.jpg?width=400&height=293&name=Picker-EPU-(Delta-Robot)-card.jpg)