Packaging Automation Solutions to Address The Grocery E-Commerce Surge

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

We have deep industry experience with a range of products - from copier toner to coffee and that includes a high application knowledge in powders. Whether you need an ATEX or NEC CLASS II DIV II compliant solution for powdered sugar, or a high-speed, twin-tube VFFS solution for spices, our broad install base includes customers with a wide variety of needs within the "powder" market.

We'd love to share what sets our packaging equipment apart when evaluating the best VFFS solution for your powder products.

What is the largest driver of success for your VFFS solution for powders? How your product is handled by the equipment during the powder filling process.

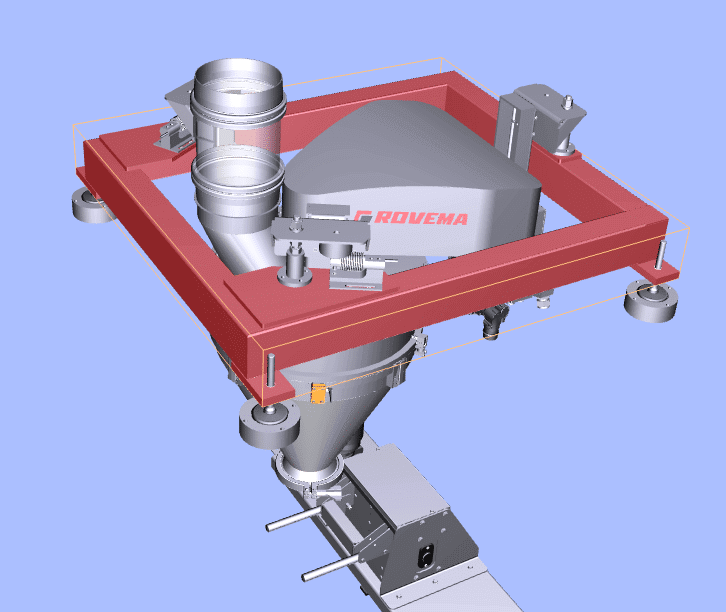

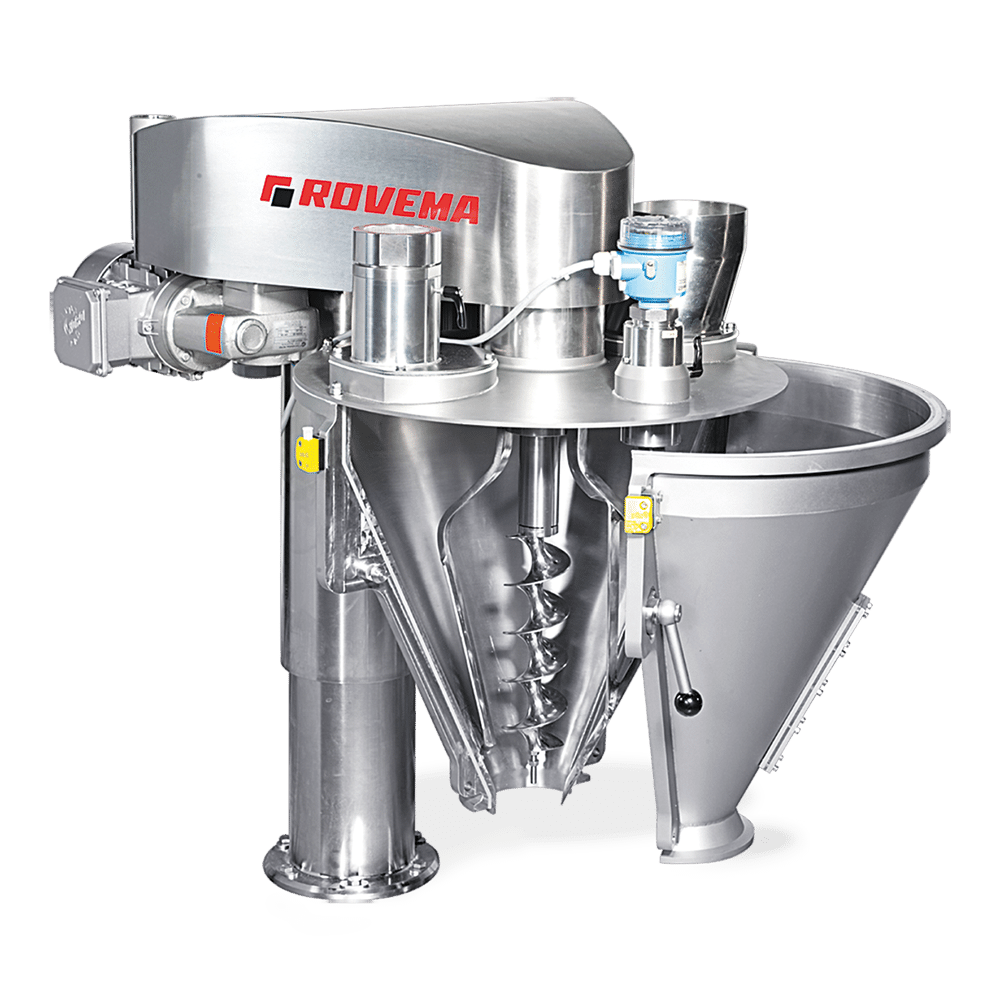

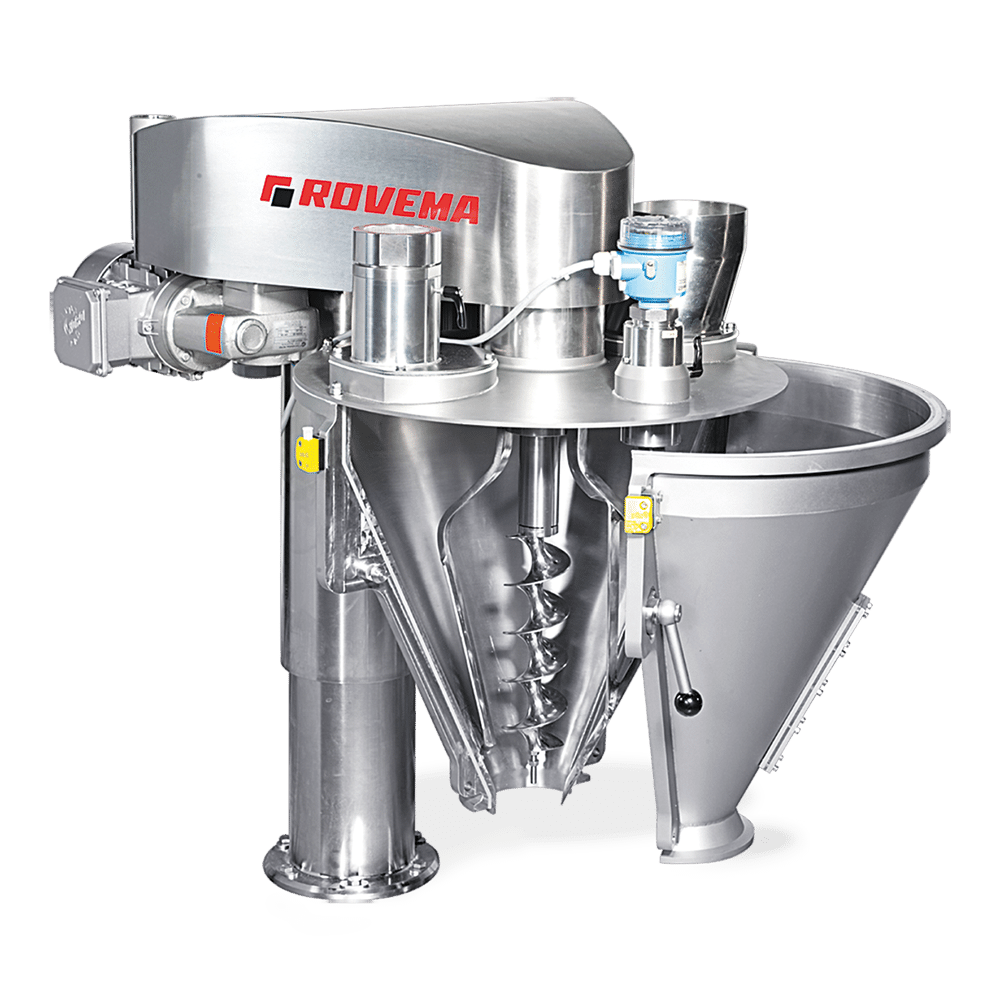

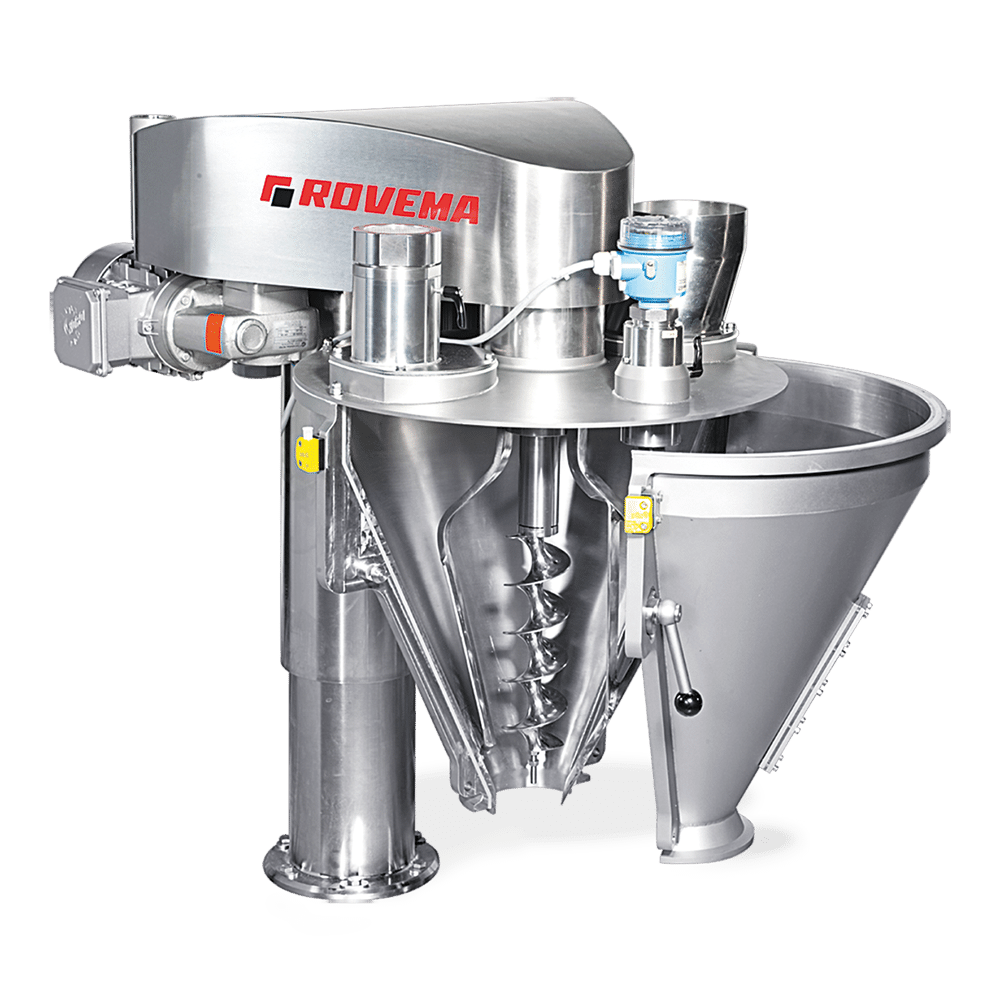

We know from experience that powder product handling is key to high weighing accuracy, dust reduction, and preventing product waste. For many high-value powder products, the horizontal feed screw that loads the product into the Rovema SD auger filler ensures that the product and head pressure level in the hopper remains constant for superior fill accuracy.

Along with other standard features like the hopper level control, split door hopper, and viewing window, the SD 81 and 150 augers also come standard with an automatic check weigher feedback feature that communicates with a downstream check weigher to monitor and make slight auger tooling adjustments if incremental weight inaccuracies are detected.

Our augers are designed to reduce product degradation. The auger itself is milled from a single piece of stainless steel with no welds for high fill accuracies and less product giveaway. The auger tooling is built in-house by Rovema, not outsourced like most others. Special design tooling available for the most difficult products and applications.

A special vacuum auger is also available for extracting air out of product resulting in product compacting (less volume and shorter bag equate to film savings), less dust, cleaner cutoff of product, and better fill accuracy. An economical auger solution is available with the SD auger (cast aluminum hopper) or an SD-H auger (hygienic design) is available in 304 or 316 stainless steel, with a 3A dairy compliant-single piece hopper.) The SD-H design is commonly found in the shredded cheese or milk powder applications within our install base.

Tool-less change over for auger tooling is standard.

Clam shell closure device is available to prevent difficult free-flowing products from getting into the bag seals.

Low profile split door auger hopper for easy maintenance, cleaning, and changeovers. Includes window for visual confirmation of product in the hopper as a standard feature.

Servo driven auger for precision and unsurpassed accuracy and reliability. (Servo controlled revolution of the auger which provides positioning accuracy of auger of+/- 0.05%)

Height adjustment for auger screw is a standard feature - minimum product drop resulting in less dust contamination and reduced product in seals.

Our base size of the Rovema auger filler for high filling accuracy of free flowing powders.

Our largest model auger filler for high accuracy for bulk powder filling operations.

Continuous motion vertical bagger technology is unmatched for powder producers. The longer fill window of the continuous motion design allows the end-user to run the auger slower to obtain better weight accuracy and still maintain high speeds. Also, the true “bottom up filling” allows for substantially less dust build-up during the powder filling process, preventing dust in seals and reducing product waste.

Aroma Perm® was originally designed for the infant formula and milk powder industry which has stringent gas flushing requirements.

Our continuous motion bagger technology is excellent for powder packaging applications.

Whether you want a small RoPack, our version of a Doy-Style stand up pouch with a recloseable feature or you need 50lb bags that can be palletized, you have multiple vffs machine model choices for your powder products.

True “bottom up filling” on these applications will create less dust build-up during filling, prevent dust in seals and ensure stronger seals because of lower drop height. The longer fill window of the continuous motion design allows the end-user to run the auger slower to obtain better weight accuracy and still maintain high speeds.

There are multiple efficiencies to be found in sourcing multiple packaging components of your production line from a single source. Of course long term, you have one place to contact for parts, support, and training.

But short term, there is no upcharge for both auger and bagger controls to be integrated into a single HMI. The electronic controls are housed in a single electrical cabinet allowing for both a simple operation and clean design with an electrical cabinet and a single power drop.

Getting your auger filler and vertical bagger from a single source eliminates potential finger-pointing at FAT or issues after installation allowing you to purchase bagger and auger with complete confidence in the performance and OEE of your full packaging line.

Evaluating a bag-in-box solution for your powdered baking mix products? ROVEMA's end-of-line packaging equipment was built with the same engineering and performance standards. The cartoning equipment and even case packaging equipment can be easily designed and integrated, leading to high levels of packaging line automation, as the full packaging line can be operated from one HMI.

Bulk powder filling automation for large sacks of products is due for an upgrade. Most solutions for bulk powders are hand-filled with large premade bags or they are very poor quality.

For many ingredients producers for the food or even pharmaceutical industries, poor seal integrity is not an option and premade packages are needlessly expensive and slow.

The Rovema REVO 6000 VFFS machine can produce gusseted sacks for powder and free-flowing products that are palletizable and have the same seal integrity and filling accuracy you can expect from the BVC family of continuous motion vertical form fill seal machines.

We have several packaging solutions within our install base that are ATEX compliant based on EU regulations as well as NEC CLASS II DIV II for US customers under OSHA.

Whether your compliance needs fall within ATEX or IECIx depending on your geographic location, many of the standards are similar and many of the ROVEMA vertical form fill seal baggers can be built to meet these high standards for being able to package combustible powder products such as powdered sugar.

Please fill out the form to discuss your NEC compliance needs with a ROVEMA technical expert.

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

Over the last few decades, as supply chains have become more complex, gas flushing products as they are packaged has...

In the world of packaging machinery, it may seem odd to refer to a diverse range of products like baking mixes, ground...