4 Ways to Audit and Reduce Pouch Packaging Material Usage

In the last couple of years, we have spent a lot of time unpacking sustainability as it relates to packaging- recent innovations, external...

4 min read

Emily Brogan

:

Updated on October 30, 2025

Emily Brogan

:

Updated on October 30, 2025

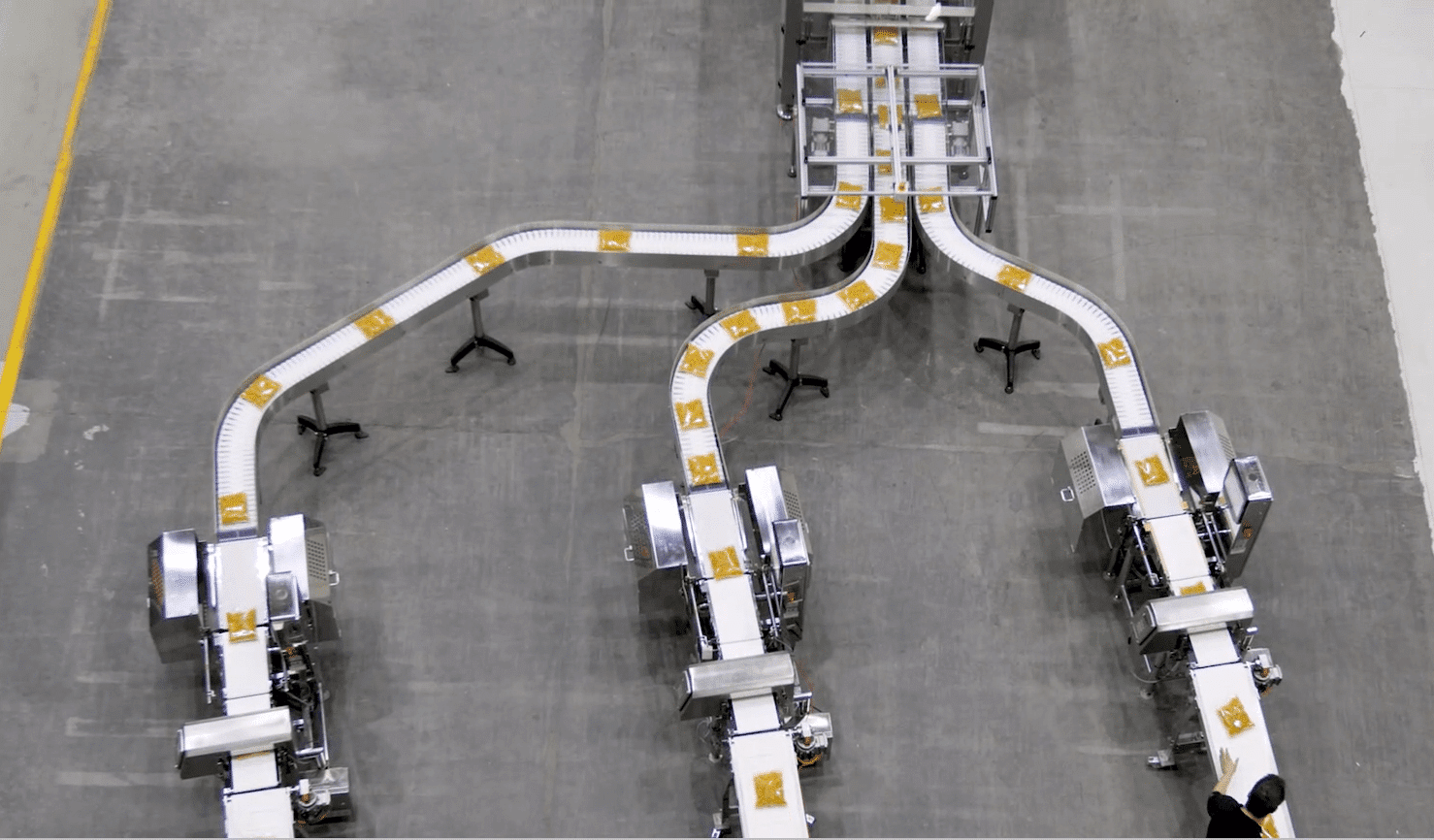

.png?width=561&name=Thumbnail%20Pasta%20Video%20(1).png) We observe a lot of end-of-line packaging machinery projects. Many for the VFFS, tray packing, case packing and filling machines that we manufacture, and many others for other vendors' equipment like combination scales, labelers, check weighers, metal detectors and more.

We observe a lot of end-of-line packaging machinery projects. Many for the VFFS, tray packing, case packing and filling machines that we manufacture, and many others for other vendors' equipment like combination scales, labelers, check weighers, metal detectors and more.

Most companies have detailed documents for engineering specification requirements, from the high level points (e.g. controller type) to the nitty-gritty details (e.g. preferred connector and bearings brands.)

Those are helpful to ensure that corporate standards for new equipment are observed. (To further improve the procurement process we recommend that buyers also consider vendor's balance sheet strength for comfort regarding long-term support.) But these are all criteria that address the selection of welded steel to solve for a specific set of technical requirements.

And that often overlooks important requirements which could often have been easily and inexpensively, proactively addressed if only they'd been identified.

In order to surface those in advance we recommend two audits precede the preparation of any RFQ. These audits are the:

Let's look at how they fit.

Many companies often reach out to us with specific but fairly general operational goals, such as the need for faster production or the ability to produce multiple bag styles on a single machine.

These goals are important and can often be achieved with the right technology-based solution. However, as we delve deeper into their requirements, we often uncover other significant pain points that also need to be addressed at the start of the project. For example:

Frequently maintenance, engineering and operations departments have gradually come to accept these issues as the "nature of the beast." Those are costly issues to accept.

Sometimes there are unique product/process considerations that are difficult to compensate for. However, these and other issues are frequently fixable - particularly with awareness and compensatory design features.

Therefore we suggest every project include an audit of current operations to look at:

With those insights, it's common to find simple problems that can be improved even in existing operations (low hanging fruit and inexpensive wins) and to identify issues that should be considered in the design of additional or replacement machines.

These provide for a richer RFQ which is based on the current situation rather than just a standard template document and also makes for a more convincing capital project request on the COO's desk.

The second audit is the market audit. This will be less familiar to many companies because it's outside of the typical engineering/vendor tech spec planning and procurement discussions.

This audit occurs at the Executive level in conjunction with marketing, sales, merchandising and brand management folks- often the same team members you would have on a well-rounded capital project committee.

The purpose is simple: identify emerging trends in consumer preference and retailer requirements which haven't yet been fully developed but are on the horizon. That may seem outside of the typical EOL packaging machinery process, but here's why it's important.

Based on current trends, for instance, around sustainability, stand-up (doy style) pouches, and shelf-ready packaging, we often find that simple tweaks can deliver the immediate capability to meet those demands in the future or simplify the addition of capabilities later, essentially future-proofing your capital investment. Examples include:

If we know that shelf-ready packaging requirements would be a factor for future contracts you want to win, then discharge heights, integrated control capabilities, package orientation and other features can be included so that required equipment can be dropped inline later to meet the need.

When the brand team is exploring alternative presentations for certain retailers, private label, or different go-to-market channels we might suggest a machine with the ability to run multiple bag styles to provide more flexibility than simply replicating the current style. This could facilitate a rapid, inexpensive expansion into stand-up pouches as consumer expectations increasingly demand.

Worried about sustainability? Knowing that's on your radar, we can include sealing system and web handling features to accommodate thinner gauge materials or even the ability to run paper on the same machine with simple material changeovers.

Will there be issues beyond those which we can use simple design modifications to prepare for? Often, yes. But we also are in many facilities in many industries and able to share observations around best practices and trends which can be helpful as well. (Obviously while carefully observing all MNDA stipulations!)

Frequently, potential market requirements go unaddressed due to the high costs associated with engineering for every possible scenario, leading to frustrating discussions between marketing and engineering teams. However, conducting a market audit can uncover opportunities to proactively prepare and seamlessly implement technically sound solutions that cater to the forefront of the business. This strategic approach ensures that the company stays ahead of the curve, delivering on market demands while optimizing efficiency.

These audits are superficially about buying the right machine.

The goal, and the benefits, however, go well beyond the buying team's analysis and comparison.

It's not uncommon that insights from these audits identify significant improvements in OEE and impending changes which can be inexpensively satisfied.

That takes a VFFS and/or case packing machinery purchase out of the simple component category and helps to leverage it in support of company strategy as a competitive advantage in higher speed, more flexible output, better retailer scores, improved consumer perceptions and reduced cost.

If you're interested in our audit process please just complete the brief form below and we'll be in touch.

In the last couple of years, we have spent a lot of time unpacking sustainability as it relates to packaging- recent innovations, external...

1 min read

In Case You Missed It: the Rovema Brown Bag Blog Series Over the past few months, we’ve been creating and sharing posts as part of our Brown Bag...

A Quick Recap: the Rovema Brown Bag Blog Series If you’ve been following along with this series for the past few months, you might want to skip...