Packaging Automation Solutions to Address The Grocery E-Commerce Surge

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

With over 50 years of expertise, we have perfected the art of packaging pasta. Our very first ROVEMA machine was designed specifically for a pasta product. Throughout the years, we have witnessed significant changes in the packaging industry, and pasta has been beautifully presented to the market in various styles. From the classic pillow bags to the traditional direct carton filling, we have also introduced more premium options like the flat bottom style bags with the gable top elegantly folded or clipped.

Do you believe that the pasta industry in the US is on the brink of a dramatic market shift as much as we do?

As margins get tighter, and sustainability becomes more of an increasingly hot topic in boardrooms and classrooms across the world, large consumer food manufacturers are pushing to drive out more costs, be more "green" and differentiate their products on the shelf.

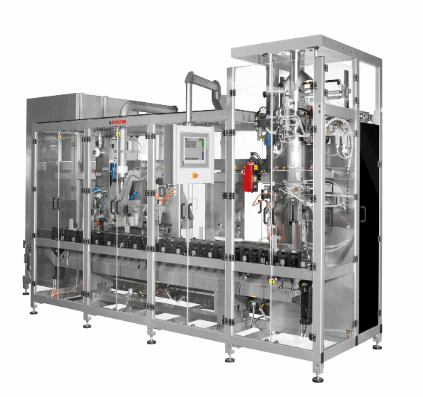

ROVEMA’s equipment offers High levels of OEE, and this is achieved by our German-engineered build quality and resulting machine performance. Our experience and engineering ensure proper execution of machines, common manufacturing, and workforce for your application. Our sales team will be ready to assist you in finding your ideal packaging solution for pasta.

Unlike other global packaging equipment companies, Rovema's expansive line of packaging equipment is actually designed, engineered, manufactured, tested and shipped from our manufacturing facility in Germany. Having your entire pasta packaging line assembled, debugged and accepted in the manufacturing facility can dramatically improve project outcomes.

Not only that, we don't add any additional costs to your project for the integration or project management.

Depending on the style of pasta, it is generally filled by a cup feeder or a scale. For pasta that is uniform in size, such as elbows, ROVEMA can offer our VDD cup filler for low-cost and efficient dosing. The cup filler can be mounted over a ROVEMA bagger or a ROVEMA vertical cartoner for a compact and small footprint. This solution offers a single control platform via the HMI. A scale can also be used for other products that tend to nest or have a unique shape. In this case, we work with a variety of scale manufacturers to offer a turn-key solution.

There are many different package styles Rovema can offer with our family of continuous motion Vertical Form, Fill, Seal Machines, from simple pillow style bags to flat bottom style bags with a shelf-ready appearance. Continuous motion is offered for pasta for gentle product handling and increased output. For a more premium look, ROVEMA offers the SBS Brick pack machine. Some of the premium styles are flat bottom style bags with the top clipped and fanned, top folded and held with reclosable tape or tin-tie, and many more…

ROVEMA can offer a traditional bag and box line with a horizontal cartoner or a vertical cartoner, CMV, which offers direct fill into a carton or bag and box. In conjunction with our cup feeders and baggers, this is a winning turn-key solution with one control platform.

In addition to filling and bag making, Rovema manufactures secondary automatic packaging machinery. Many pasta shapes, like tube-shaped pasta, require careful consideration when designing packaging equipment to handle these fragile products. Because it was designed with VFFS machines in mind, Rovema case packing equipment excels in handling flexible packages.

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

The Rovema Brown Bag Blog Series: The Final Chapter This blog marks the sixth and final installment of our Rovema Brown...