The Brand Manager's Guide to VFFS Bag Styles

Understand the strengths, considerations, variations and best practices of VFFS package styles:

Vertical Form-Fill-Seal bag styles are often selected by default. It’s considered one of numerous technical specs in a machine design - along with min/max package dimensions, speed, secondary packaging integration, controller type and even cylinder and bearing types.

Bag styles impact every aspect of the operation from production speed and cost, through retailer satisfaction and product sell-through, to competitive differentiation and market perception.

Even deciding between different variations of stand up pouches like a doy bag versus the classic flat bottom bag come with their own unique mix of advantages and considerations.

It takes months, sometimes years, to launch a new product which you then entrust to a package to keep it fresh, help it sell itself in competitive markets, and help position your brand as the trusted consumer option.

That’s a tall order for a bit of plastic, foil, and/or paper. But not only can the package deliver all that - it can also give you a huge leg up in the market if you understand what’s possible.

We have created this free 19-page guide to VFFS package styles and the market considerations that you'll weigh when evaluating the best bag style for your products, including:

- What recent trends and packaging machinery capabilities are shaping the CPG industry, like stand-up pouch packaging.

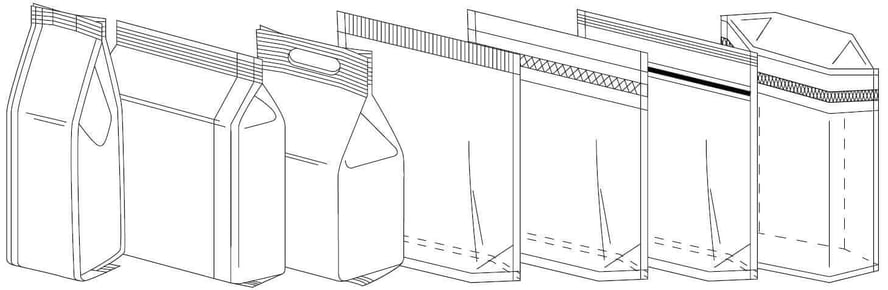

- The comparative strengths and considerations around a variety of VFFS bag styles, like the flat-bottom bag.

- Current variations of these bag styles like stand-up pouches with a zipper, tape, asymmetrical vertical seals or even carry handles.

- How competitive differentiation of your products can kick start your revenue growth.

Free Guide Download

“Good employees that are easily accessible. Solid equipment.” - John B.

%20(1)-1.png)