Maximizing Modified Atmosphere Packaging: Key Factors for Success

Over the last few decades, as supply chains have become more complex, gas flushing products as they are packaged has...

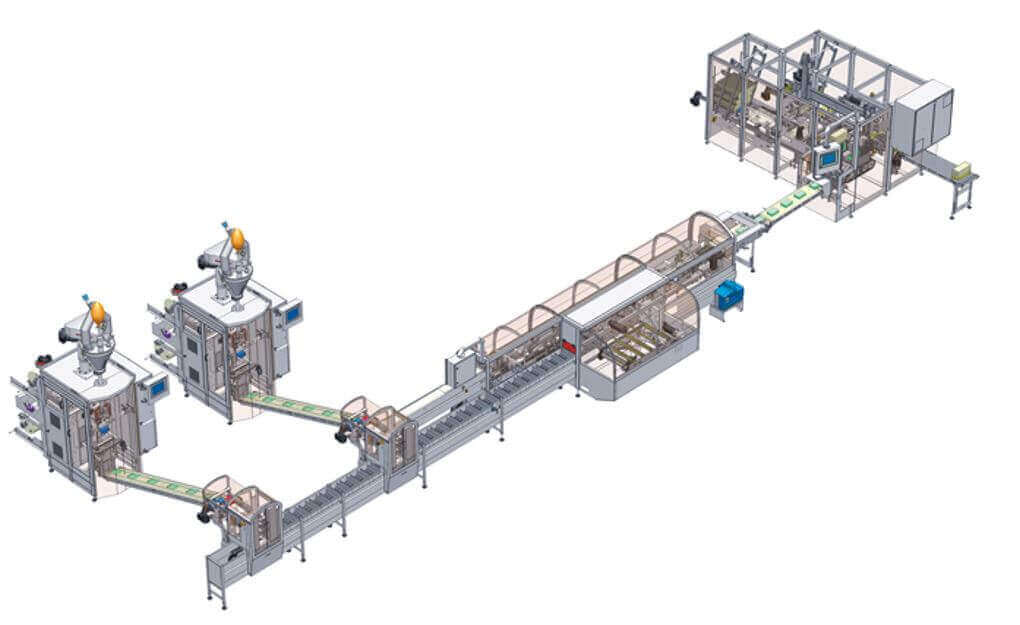

If you package powdered baby formula, you know that creating the highest quality, safest, and healthiest product for the market is your highest priority. Your products sustain the next generation. How you package baby formula as well as what you package it in should be equally as safe, healthy, and fast. Our technologies and solutions are exceptionally suited for the high quality and safety requirements for Powdered Infant and Baby Formula.

Rovema Leads Packaging Technology Innovation and understands each application. Over 60 years of experience have guided us with the features we are known for. Below are just a few as Rovema continues to develop long-term solutions for powdered infant and baby formula.

.png?width=714&height=514&name=Untitled%20design%20(49).png)

ROVEMA’s equipment offers an unmatched ROI and exceptional levels of OEE. These are achieved by our German-engineered build quality and resulting machine performance. Our experience and engineering ensure proper execution of machines, common manufacture, and workforce for your application.

Our sales team will be ready to assist you in finding exceptionally safe and efficient packaging solutions for your powdered baby and infant formula products.

Over the last few decades, as supply chains have become more complex, gas flushing products as they are packaged has...