Packaging Fuels Holiday Traditions

Holiday traditions feel deeply personal – morning coffee rituals, familiar seasonal snacks, the same confections...

Rovema has been packaging spice for decades all over the world. The spice group is one of the most dynamic product group from Paprika, to peppercorns to bay leaves. Spice has been packaged in many types of packaging styles from pillow bags to more premium styles in flat bottom style bags with a gable top featuring a zipper reclosure or tin tie. Spice is also introduced with other products such as rice, and many other food items.

Due to the wide variety of Spice products, the items can be filled with many different methods. For powdery type spices, such as Paprika, it can be dosed with ROVEMA servo auger filler, model SD. For spice products that are more uniform in shape such as salt or peppercorns, the spices can be filled by a cup feeder.

Either one of ROVEMA’s VDD cup fillers or SD auger filler is an efficient dosing solution. They both can be mounted over a ROVEMA bagger for a compact and small footprint. This solution offers a single control platform via the HMI. A scale can also be used for spice products such as bay leaves. In this case, we have established relationships with a variety of scale manufacturers to offer a turn-key solution. In some cases, multiple fillers are used for a product mixture.

There are many different package styles Rovema can offer with our family of Vertical Form, Fill, and Seal Machines from simple pillow-style bags to flat-bottom-style bags with a shelf-ready appearance. Typical vertical bag applications for rice can utilize a variety of films such as heat-sealable laminates, or LDPE films.

Additional recloseable features can be offered such as a zipper reclosure. An intermittent or continuous motion vertical bagger can be offered for spice applications depending on the application requirements. For customers who want to provide a premium bag and eliminate the glass or plastic jars, ROVEMA offers the SBS Brick pack machine. ROVEMA can provide flat bottom style bags with the gable top folded with a tin-tie or recloseable tape. This style will reduce your carbon footprint and reduce your overall packaging costs.

ROVEMA can offer a traditional bag and box line with a horizontal cartoner. In conjunction with our auger fillers, cup feeders, and baggers this is a winning turn-key solution with one control platform.

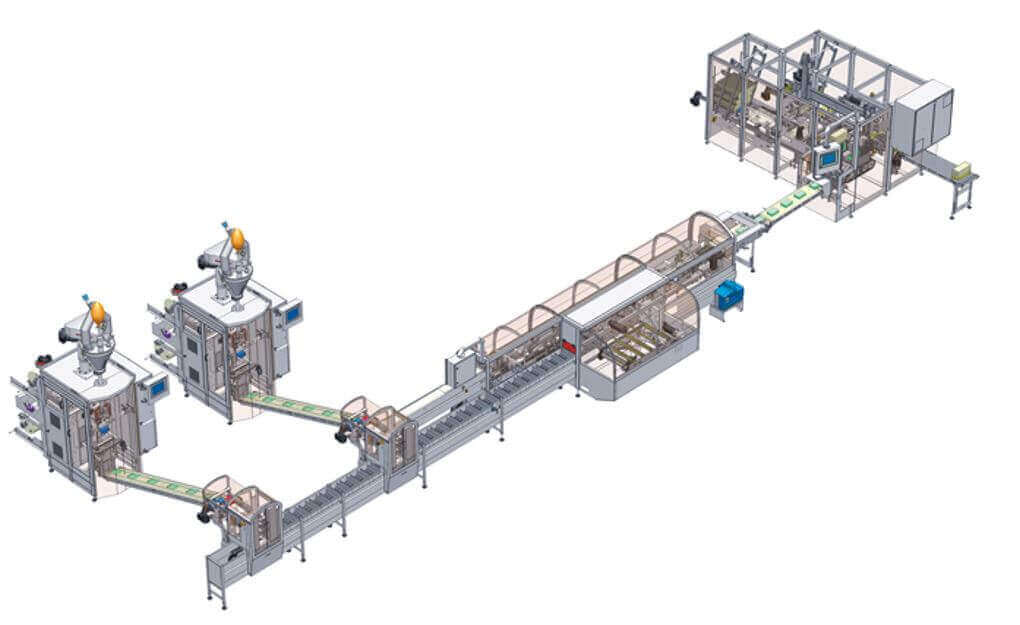

In addition to filling and bag making, Rovema manufactures secondary automatic packaging machinery. We can deliver a complete automatic turnkey packaging line for dosing, bag making, coding, inspection, and casing. The turnkey solution is engineering and built in one facility with a common workforce.

This minimizes complication and risk for the turnkey solution. Case styles can be offered from the RSC case, trays or tray and lid applications.

ROVEMA’s equipment offers an unmatched ROI and exceptional levels of OEE. These are achieved by our German-engineered build quality and resulting machine performance. Our experience and engineering ensure proper execution of machines, common manufacture, and workforce for your application.

Our sales team will be ready to assist you in finding your ideal packaging solution for your spices, sugar, salt, and herbs.

Holiday traditions feel deeply personal – morning coffee rituals, familiar seasonal snacks, the same confections...

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

In the world of packaging machinery, it may seem odd to refer to a diverse range of products like baking mixes, ground...