Rovema Exclusives

Necessity Is The Mother Of Invention

Rovema has been the pioneer of industry solutions for 60 years.

The technical capabilities of our packaging equipment aren't about us as much as they are about our customers. Each innovation, patent and feature has a story and common genesis- a customer or industry faced a packaging challenge and needed someone to solve for the solution.

Evaluating Your Solution

VFFS machines are an efficient and reliable method for packaging a wide variety of product types. And no matter what you are bagging, your priorities likely fall in the same ballpark of most other product types, bag styles or industries.

You'll stack these in different orders of priority depending on what you're packaging but these are probably your comparative metrics when vetting out the best VFFS solution for your products:

- Seal Integrity

- Production Speed

- Bag Style Quality

- Machine Reliability

- After-Sales Experience

Of course there will be other factors that come into play like the ability to build out a fully integrated packaging line, the financial stability of the vendor, et cetera.

But, if a potential vendor drops the ball in any of these 5 areas, they probably won't make the cut- and justly so.

It's those opportunities that get us excited to come to work every day.

The following technologies are all patented innovations offered by Rovema equipment, and almost all of them are standard features for the solution you may be considering.

Want to Learn More?

%20with%20zip%20Bag%20Style.png?width=1772&height=1772&name=Rovema%20Ropack%20(Doypack)%20with%20zip%20Bag%20Style.png)

RoPack®

Our patented process for creating a doypack style stand-up pouch, with all of the space efficiency benefits of a vertical form fill seal machine.

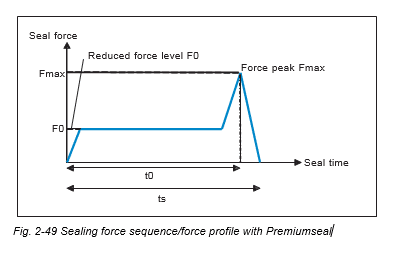

Premium Seal®

Two phase sealing cycle during the D-motion allows the jaws to pre-heat the film before sealing, producing the strongest seals in our industry. At blistering speeds.

Sense and Seal®

Completely servo-driven sealing system allows seal jaws to detect products as light as a marshmallow, preventing not just a sticky mess, but wear of the sealing system.

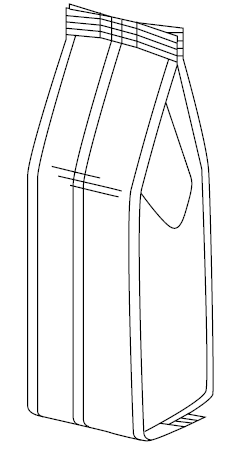

Stabilo®

Invented by Rovema, this stand-up pouch is a variation of the block bottom style bag with four (quad) seals in each of the vertical corners, giving it rock-solid shelf stability.

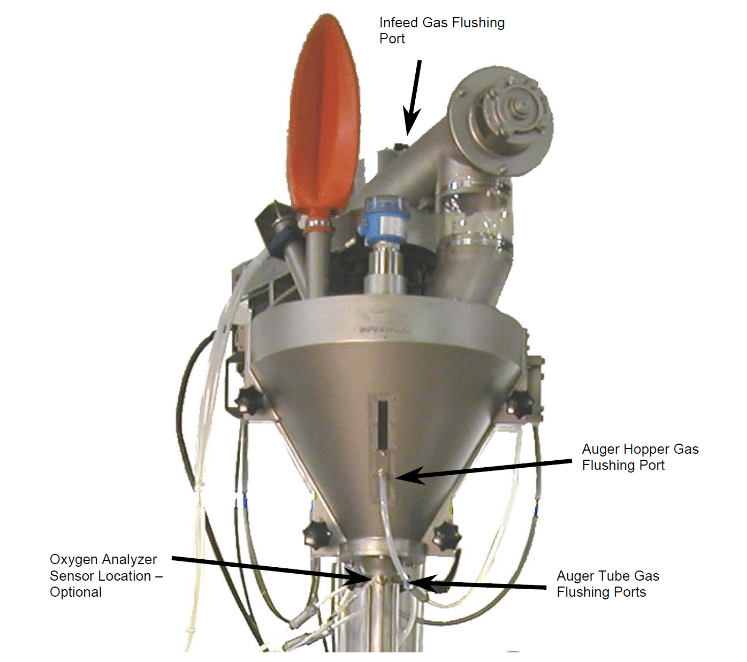

Aroma Perm

A gas-flushing solution that achieves less than 1% residual oxygen to extend the shelf life of coffee, milk powders or chemicals.

Maximized Uptime

When you invest capital in a project you expect the machine to perform as designed. That's a given. We've built our ongoing support program around a few simple principles:

- If your machine is still running you should still be able to get parts and service, no matter how old it is.

- When you call, we should have a knowledgeable technician available to help.

- Retrofits are a normal part of business - not a distraction.

Connect The Dots

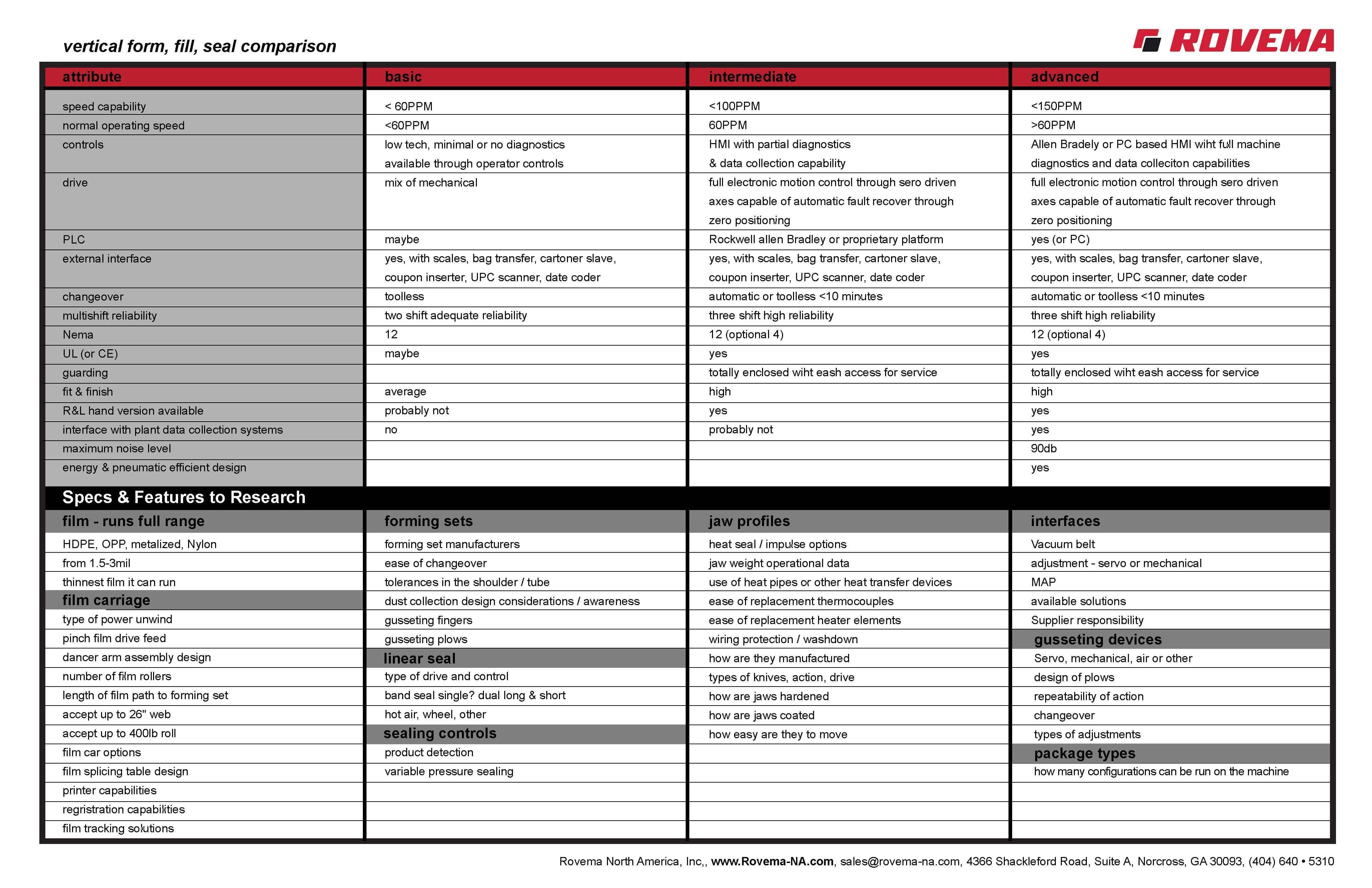

We talk about features, footprints, film drives, and food applications, but when it comes to the basics- speed, motion, controls, etc, how does Rovema compare and what other questions should I be asking?

Capital equipment involves big decisions and you need to do your due diligence to vet out the best VFFS solution for your company- even if it's not us.

We've put together a buyer's comparison worksheet that you can use to kick the tires on several vendors- and we went ahead and filled in our part for you.

BVC Family of VFFS Machines

Our VFFS machine solutions cover a wide span of product-specific model types from liquid products, to frozen products, and basic products like snacks.

Other BVC models are built to maximize the flexibility of package styles or film materials with a tool-less changeover from a simple pillow bag to a RoPack® doy-style stand up pouch.

They have one thing in common- they can be equipped, and often come standard regardless, with every technology above.

No End Of Life

When your VFFS packaging line was built under a single roof in Fernwald, Germany, it wasn't built to last 10, 15 or 20 years, it was built to last a lifetime. We are intentional about making new innovations available as often as possible for older Rovema Machines.

The only time you should have to shop for a new VFFS machine, is when the new technologies are too drastic to be retrofitted to your existing one, but make purchasing a new machine worthwhile.

You can learn more about replace vs rebuild considerations here.