Rovema Machines

Vertical Form Fill and Seal

Vertical baggers are the heart of our machinery program. Our range of equipment includes intermittent and continuous motion baggers.

Numerous variations address specific industry requirements and incorporate features for compliance with safety, food & pharma regulations.

Many of the key technical advances in vertical bagging technology originated with Rovema. Inline cartoning, continuous motion, Stabiloseal, brick packs and dual-access servo were all first found on Rovema's equipment.

At the heart of our equipment is the sealing technology key to shelf life, cycle speed and reduced material cost.

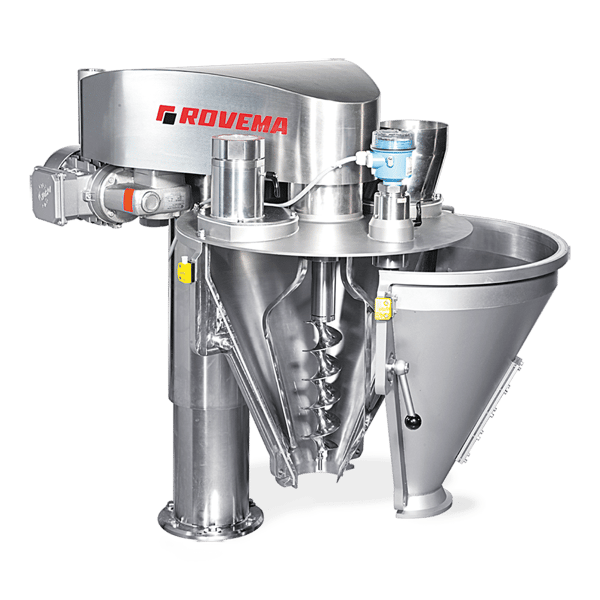

Filling/Dosing/Weighing

How much product can you afford to give away?

Probably none - and yet inaccurate weighing, filling & dosing is one of the most common frustrations with V/F/F/S solutions.

Our range of solutions includes volumetric, auger, and scale solutions with specific features for common challenges.

And our German obsession with accuracy is on full display here, as is our commitment to elegant engineering and integration. Many of our baggers can be equipped with optionally integrated filler controls in the bagger controller.

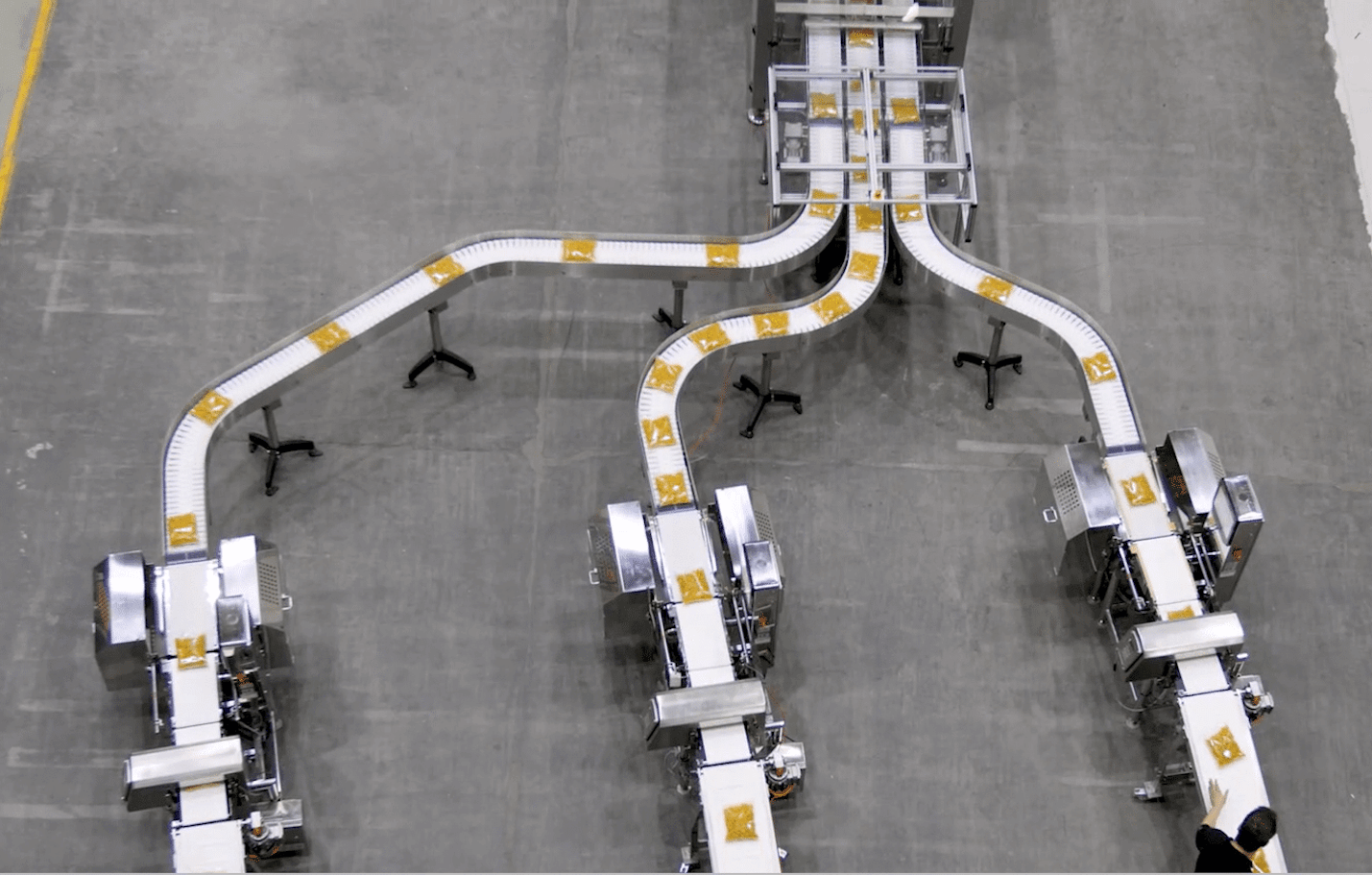

End of Line

It's not enough for your vertical bagger to run at a blistering speed with no package rejects...those bags must be placed in cartons, or packed in trays and cartons for unitization and safe transport to the retail destination.

It's easy to assume that the traditional cartoner is the right one to integrate; or that the tray packing can continue to be done manually.

Projects for new lines, though, often incorporate end-of-line packaging automation technology which not only provides integrated controls and common parts and maintenance procedures but substantially simplifies commissioning through single source responsibility, off-site integration, and full line factory acceptance tests.

What Makes a Rovema Machine Different

Sustainable Packaging

Acting in modern times means taking responsibility for people and the environment. We're partnering with companies to explore and test sustainable options.

Efficient Machines

Planned Obsolescence for VFFS machines is a concern of the past for our customers. Our experts will gladly take you through a free efficiency audit.

Rovema Exclusive Technology

With true single source solutions, you can rest assured that we've fine tuned every stage of your packaging process... and patented some of them.

Life Cycle Services

As an organization, we stand behind our "no end of life" principle. This pillar of our after-market experience is one of the reasons that our return on investment is unmatched.

We also reject the industry mindset that after decades of running your VFFS machinery, it's expected (and accepted) that you'll see an incremental drop in speed and quality.

This is unacceptable to us so if you're experiencing any drop in efficiency, know that for our customers, we're committed to restoring it.

Paper Packaging Guide

Maximizing OEE for Vertical Bagging Ops

Bag Type and Machine Selection Guide

.png?width=259&height=432&name=shelf-ready-packaging-sidebar-cta%20(1).png)