Filling, Dosing, and Weighing

Why You Should Use Rovema's Filling, Dosing, & Weighing Machines

Your feeding, dosing or weighing solution is critical to your application. Whether selling by volume or weight, you've got to be spot on. Margins are too tight to give product away, and expectations for operational efficiency demand that the perfect weight/volume product charge is efficiently transferred into the bag with every cycle.

Awkward transitions and other improper set-up/adjustment can lead to strung-out product which is the leading cause of sealing problems.

It's not all science. Call it art, black magic or just many years of experience - but there's another big factor in the right integration with a bagger. Some products really are better dosed as components before they're mixed, and others don't flow as expected because of unique attributes.

We're happy to explore options with you, conducting tests as required.

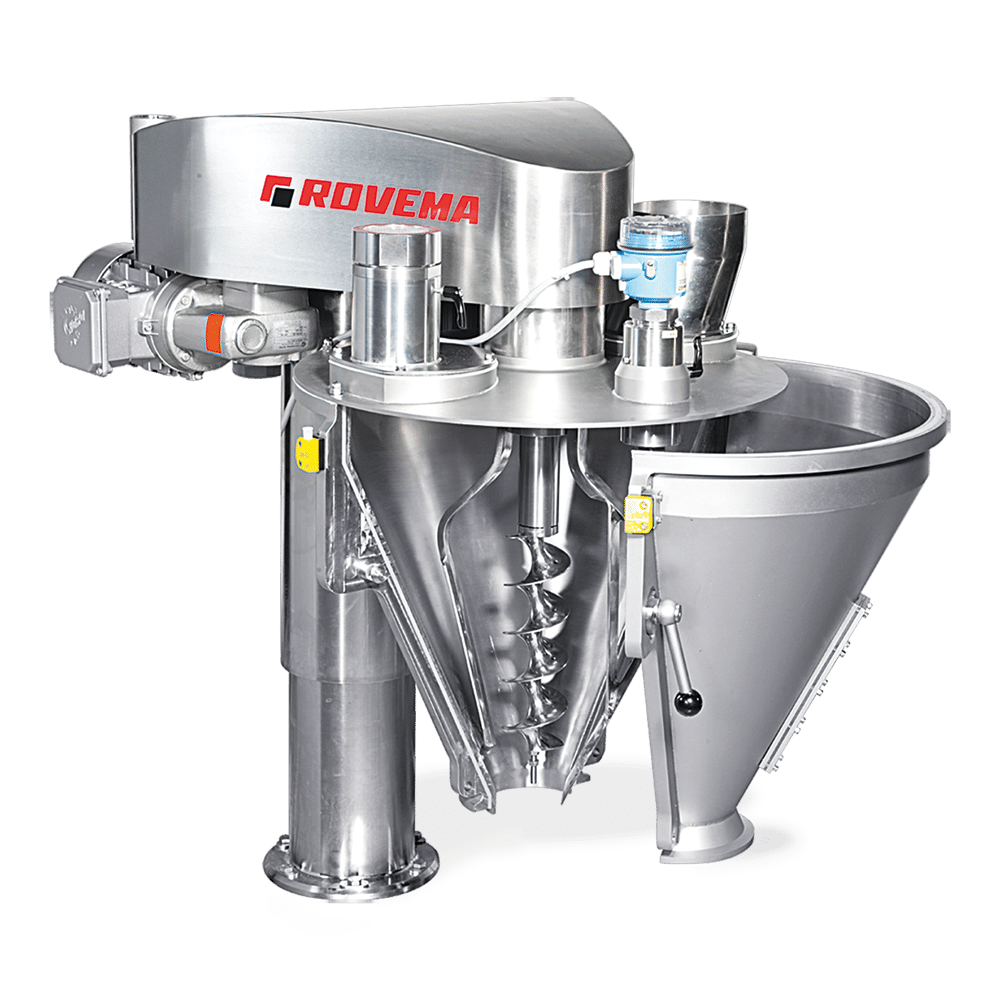

If our cup filler or auger dosers are well suited for your product, you realize an extra benefit. Not only are all components manufactured, integrated and run out under the same roof, but controls can be integrated for a single HMI to operate the system.

Integrate Your Scale Of Choice

Some products aren't well suited to cup and auger-style dosing. Rovema baggers are integrated with a wide range of commonly known scales in applications around the world.

Whether Ishida, Multipond, Multiweigh, Yamato, or many others, we help companies compare options for integrating the scale that best meets their requirements with the optimal Rovema V/F/F/S solution.

We Can Help you Find the Right Machine for Your Product

More Information About Filling, Dosing, and Weighing Machines

For the efficiency of your production line, your methods of feeding and filling of the product will often have more of an impact on speed.

Sourcing your solution from the same engineers, under the same roof, as the ones that designed the rest of your line ensures the fully integrated and intricately customized solution you're promised comes to fruition without any surprises.

Maximizing Operational Equipment Effectiveness for Vertical Bagging Operations

It's a critically important topic across manufacturing industries - and it's one that we're committed to fostering dialog around.

As an organization, we stand behind our "no end of life" principle.

We also reject the industry mindset that after over the decades of running your machinery that it's expected that you'll see an incremental drop in speed and quality.

This is unacceptable to us so if you're experiencing any drop in efficiency, know that for our customers, we're committed to restoring it.

Download this guide based on our methodical efficiency audit process.