Packaging Fuels Holiday Traditions

Holiday traditions feel deeply personal – morning coffee rituals, familiar seasonal snacks, the same confections...

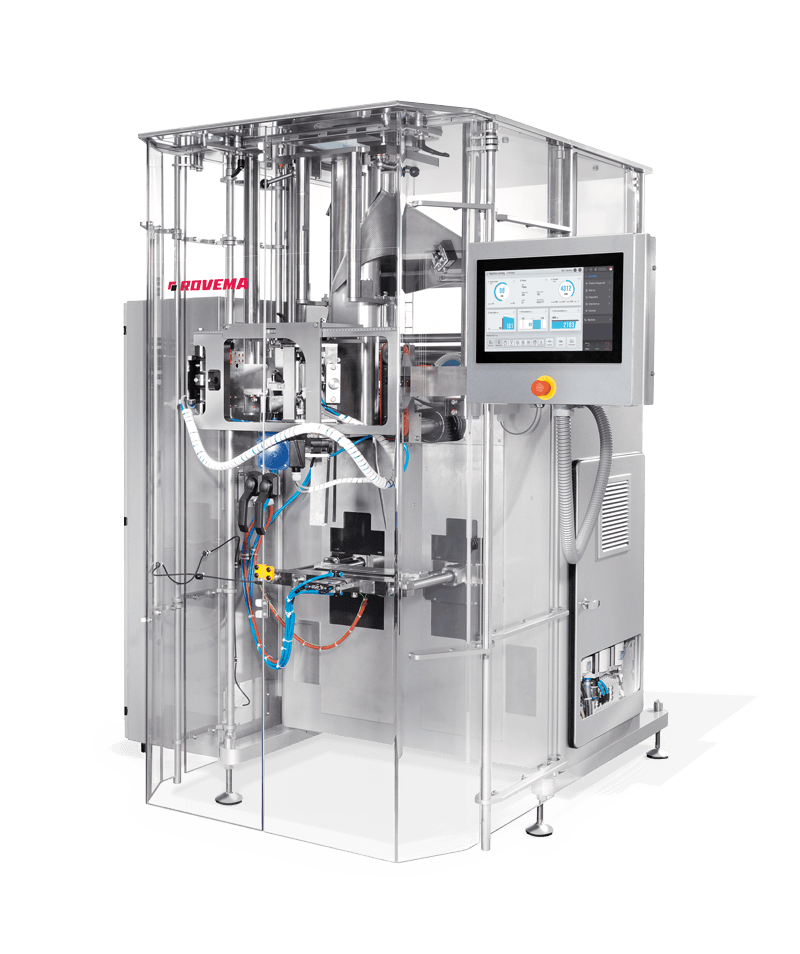

Rovema offers several solutions for your packaged Bakery and Snack needs. There are multiple continuous motion models Rovema can offer. The BVK and BVC series continuous motion baggers with fully integrated scales are trusted by our customers in the snack Industry. For lower output or basic pouch styles and sizes the intermittent BVI is offered. All Rovema models can be integrated with a Rovema filler, an existing filling system, or a new filling system of your choice. Each application would be reviewed with the filler supplier and designed and built to your specific needs and requests, then tested and proved as needed to provide the best and most efficient stack-up.

Best performance starts with a steady supply of product to the fillers, Be it Horizontal motion, vibratory or belts a steady and consistent supply of product is the beginnings the great performing line

Small inlet funnels keep the charge from expanding outward traveling from one transition to another and maintaining falling speed

Steep angles keep the charge focused and minimize swirling

Integrated forming set / funnels minimize change parts and speed changeovers

Bias-cut funnels increase speeds and minimize bridging

Smooth, Dimpled Stainless Steel shoulders are options to choose from

There are various coatings that can be applied to minimize sticking and extend shoulder wear

Epoxy shoulders can be an alternative

Integrated Funnel / Transition are options

Shoulder angles can be modified for special needs and difficult films

Round, Oval, Square, and other shapes are available for special needs

Snack tube / open back former are helpful with very small formers and bridging

Swing gates at the bottom of the forming tube can protect films from sharp and hard edges

Product clamshells can be used to slow product down

Rovema Leads Packaging Technology Innovation and understands each application. Over 60 years of experience have guided us with the features we are known for. The following are just a few as Rovema continues to develop long-term solutions for the packaging industry.

Holiday traditions feel deeply personal – morning coffee rituals, familiar seasonal snacks, the same confections...

Shifting preferences in snack foods and consumer attitudes heighten the demand for packaging equipment that’s built for...

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...