Packaging Automation Solutions to Address The Grocery E-Commerce Surge

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

According to AFFI, the American Frozen Food Institute, the frozen food market experienced a 21% increase in retail sales in 2020 alone and while the packaging demands of this market call for many of the same priorities like filling accuracy and package quality, the tough environmental and hygienic demands call for equally tough equipment.

The Individually Quick Frozen (IQF) market has been exploding over the past 10 years offering new products and packaging styles in the freezer section at the local grocery stores. IQF products are packaged in many forms in today’s market. From the traditional LDPE pillow bags, and bag-in-box packages, to more premium styles in flat bottom style bags with a gable top featuring a zipper reclosure or multi-component meals. IQF covers a wide variety of products from frozen vegetables, ready-made meals, and meat.

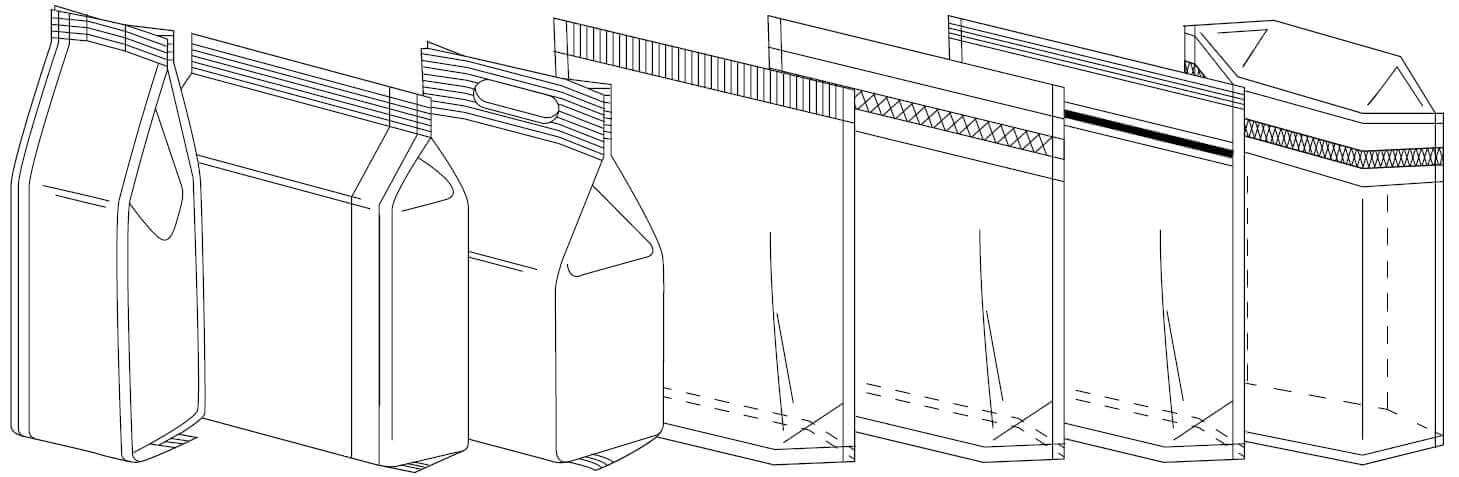

There are many different package styles ROVEMA can offer with our family of Vertical Form, Fill, and Seal Machines, from simple pillow style bags to VFFS-made doypack style bags with a shelf-ready appearance. Typical vertical bag applications for IQF can utilize a variety of films, such as heat-sealable laminates or LDPE films.

Additional reclosable features can be offered, such as a zipper reclosure or tape reclosure for the full range of bag styles. An intermittent or continuous motion vertical bagger can be offered for IQF, depending on the application requirements.

ROVEMA’s construction on the BVC series is a solid frame for better hygiene and eliminates tubular construction. Finally, the BVC series has many 3A features and may be a fit for dairy and meat applications. The BVC-400 was specifically designed for the IQF market.

From the same award-winning continuous motion VFFS family, fit for your frozen products.

Just announced, the modular REVO model is designed for reliability and your budget in mind.

Unlike other global packaging equipment companies, Rovema's expansive line of packaging equipment is actually designed, engineered, manufactured, tested and shipped from our manufacturing facility in Germany. Having your entire IQF packaging line assembled, debugged and accepted in the manufacturing facility can dramatically improve project outcomes.

Not only that, we don't add any additional costs to your project for the integration or project management.

ROVEMA Machines revolutionize the Frozen Food Industry with their unrivaled return on investment (ROI) and exceptional levels of Overall Equipment Efficiency (OEE). These remarkable achievements are made possible by the superior German-engineered build quality and resulting machine performance. Our extensive experience and engineering expertise guarantee flawless execution of machines, ensuring consistency in manufacturing and workforce for your specific application.

We would love the opportunity to demonstrate how our bagger options are uniquely tailored to meet the stringent hygienic requirements of your frozen products.

If you're not quite ready to engage with one of our machine experts, we recommend starting with our Frozen Packaging Guide. This resource will provide you with a comprehensive understanding of how our machine models compare, the critical factors to consider when evaluating a frozen packaging solution, and inspire you to think more creatively about the diverse bag styles and material options available.

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed...

Sustainable packaging materials are becoming increasingly popular, and many of today’s CPG brand teams and other...

Editors Note: This blog was originally published in October of 2017 but has been edited and republished with additional...