Brown Bag Blog Series Pt. 4: Using Sachet Bags with 3 & 4 Side Seals

A Quick Recap: the Rovema Brown Bag Blog Series If you’ve been following along with this series for the past few months, you might want to skip...

5 min read

John Panaseny

:

Updated on August 8, 2025

John Panaseny

:

Updated on August 8, 2025

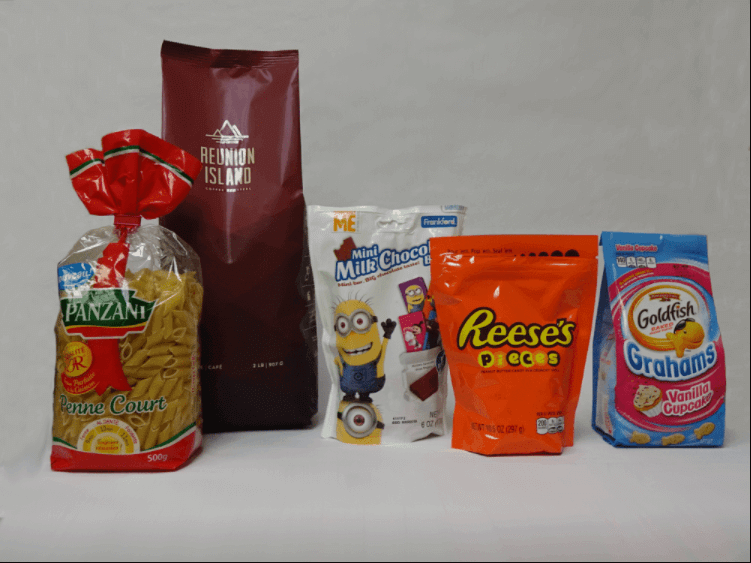

With the ever-increasing demand for Stand-up Pouches and bags, more and more food producers are asking machine builders – "Can I create my horizontally made stand up pouch on a VFFS machine?" The potential answer is yes, but there are important factors to consider. To determine if this goal can be achieved, it is crucial to understand the characteristics and distinctions between HFFS vs VFFS technologies. Let's first define how an HFFS machine operates and how this is different compared to a VFFS machine.

Like a VFFS machine, a horizontal form fill and seal machine takes a roll of film, forms it into a package, fills the package, and seals it - all on one machine. But, as these actions are happening, the film is traveling in a direction that is mostly horizontal to the ground or base of the machine itself.

A key difference in the packaging process as well when comparing VFFS vs HFFS is that the package itself is usually sealed and cut prior to being filled, with a couple additional stations and moving parts needed to open the packages and fill them. Alternatively, for VFFS-made stand up pouches, the packages are filled, sealed, and then the final cut is made.

When evaluating a machine type to produce stand up pouches for free-flowing products, there are several key factors and decisions to take into consideration that set HFFS and VFFS machines apart.

Key items to consider when evaluating VFFS vs HFFS Machines:

Key items to consider when evaluating VFFS vs HFFS Machines:The fundamental difference in how each machine type operates is what introduces constraints on the film type. An HFFS machine takes a roll of film and runs it over a plow, which is what creates the bottom gusset in a stand up pouch, such as the popular doypack.

The horizontal film path over the plow minimizes the force required to pull the film from the film carriage and through the machine. On a VFFS machine the film roll is unwound in an upward direction and then pulled over a forming collar with a change in direction of greater than 90⁰. This change in direction requires more force than a typical HFFS machine requires. Therefore, more rigid films (like paper/poly/foil/poly) can be trickier to run on a VFFS, and require tools like a power unwind to help push film from the back of the film carriage. The introduction of the power unwind technology for VFFS machine film carriages in the last decade greatly improved film material flexibility.

Another important consideration in regards to the material itself is that films for use on a VFFS must have a different coefficient of friction on the inside of the film than on the outside of the film so that it can properly be transported over the forming collar but can also be gripped properly by the draw-down belts.

What is interesting to note is that the same limitation on VFFS for rigid films, works in the opposite direction for monolayer films like straight PE. These films can be run on a VFFS machine but not typically on a HFFS machine.

Another important aspect to consider is the sealing process employed by both HFFS and VFFS machines, as it greatly impacts the final appearance and quality of the package. In the case of HFFS machines, the film is folded flat after passing over the plow, resulting in a package with two dimensions. This allows the film to undergo a series of seal stations where it can be preheated, heated, and cooled in multiple indexing cycles. All of these steps allow for extra conditioning of the seals.

In the VFFS process, the seals are produced at the same time that the bag is being filled and sealed. While this synchronization makes for a much more efficient process, all preheating, heating, and cooling are limited to the time within a single sealing cycle. The net result of these process differences is that the side and bottom seals can have a less refined look, but using a completely servo driven sealing system like Premium Seal® , which was created to address this and other challenges, helps to dial in the appearance and integrity of these seals at high speeds.

It is important to speak with your potential VFFS machine supplier to test your film to determine how it will perform on their equipment and what technologies are available to achieve the bag style quality you need.

Differences of Finished Package Fill Volume of Vertical vs Horizontal Baggers

Differences of Finished Package Fill Volume of Vertical vs Horizontal BaggersThe third item to consider has to do with fill volume. Or in simple terms, how full is my pouch/bag when it is finished and sitting on a shelf. This is a very important item to consider if you are considering or even converting from an existing HFFS stand up pouch to a VFFS produced stand up pouch. Again the difference comes from the varying processes.

When using a horizontal form fill and seal machine, the filling process occurs from the top, allowing for the bottom gusset of the pouch to be fully available. This means that the pouch has its full potential volume when the product is dropped into it. Typically, HFFS made bags are filled to about ⅔ to ¾ of their capacity due to this process.

On the other hand, achieving the same fill volume on a VFFS machine can be more challenging. This is because the bag is being formed and sealed simultaneously while the filling process takes place through the side of the stand-up pouch. As a result, the gusset at the bottom of the pouch is only partially open during this stage, leading to a reduction in the package fill volume. Just like with HFFS machines, it is crucial to leave enough headspace in the package to prevent excess product from interfering with the seal jaw.

A further difference in fill volume also occurs when a recloseable zipper is part of the stand up pouch. In the HFFS process. the zipper is open when filling through the top and minimizes fill volume restrictions.

In a VFFS process, the zipper is closed during the filling/sealing process and therefore limits the available volume for filling of the product. It is important to check with the VFFS machine supplier to determine whether your existing bag can be run on a VFFS machine with no finished product amount change to the stand up pouch. If you are developing a new package to be run on a VFFS machine, this fill volume topic can be accounted for in the initial design.

Also, thanks to servo-driven sealing, often a product stripping motion, where the sealing jaws come within a few millimeters of each other and move down the package to help the product to settle prior to sealing. This solution helps to reduce the needed headspace, particularly for VFFS made doy style packages.

One other question that often comes up during this discussion is, "Can my existing VFFS machine can produce a stand up pouch?"

It may be possible, but it would be best to check with your VFFS machine supplier to make this decision. The most common challenges are that older machines may not have the registration tolerances or gusseting ability to produce a good looking package and therefore new equipment is the best solution.

For ROVEMA packaging machine owners, a retrofit, the Stabilo Seal® Stand-Alone Unit, has been available for years that can be used with all Rovema continuous form, fill and seal machines for the production of these premium bags styles.

If your project to produce a vertically made stand up pouch passes these checks, you will be in for some pleasant added benefits. Most often, a VFFS machine making SUP’s will take up substantially less space in your plant. For reference, a standard BVC VFFS machine, has a footprint of about 7'x 6' while an HFFS for stand up pouches is often 2 to 3 times the footprint size.

Additionally, a VFFS usually offers greater flexibility of bag styles. It is not uncommon that the same VFFS can produce a pillow bag, a gusseted bag, a gusseted flat bottom bag and a vertically made stand up pouch all on the same machine with minimal change over time and between them - with the right vffs solution, the changeover is completely tool-less.

So when your colleagues or boss ask the question, “Can we produce this horizontally made stand up pouch on our VFFS machine?

You can answer potentially yes, but we need to consider a few items.

A Quick Recap: the Rovema Brown Bag Blog Series If you’ve been following along with this series for the past few months, you might want to skip...

Here are some interesting statistics for you. Stand up pouches are expected to reach 33.4 billion USD globally by 2020. From 2015 to 2020, they have...

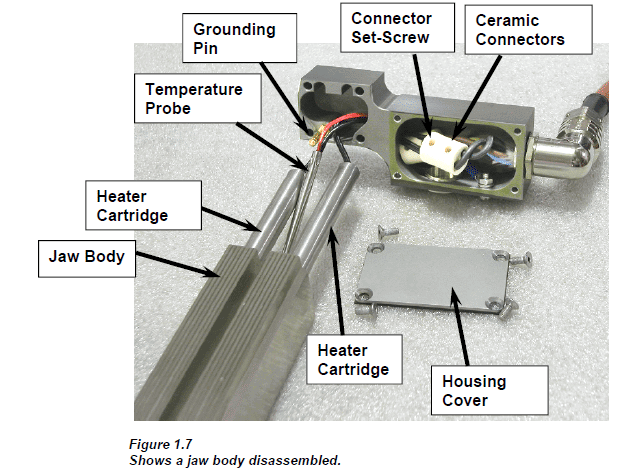

If you're hands-on with packaging machinery, you likely spend a lot of time making sure your packaging machinery stays up and running, changing wear...