4 Ways to Audit and Reduce Pouch Packaging Material Usage

In the last couple of years, we have spent a lot of time unpacking sustainability as it relates to packaging- recent innovations, external...

4 min read

Emily Brogan

:

Updated on August 20, 2024

Emily Brogan

:

Updated on August 20, 2024

Often people try to isolate a mechanical factor for VFFS inefficiency, for instance, sealing. And that's often the case. But before jumping to conclusions it's always important to take a system view of the entire mechanical stack-up, environmental factors, and film.

Everyone's aware of a significant change - like between film suppliers - but sometimes very subtle factors can manifest in frustrating ways. One example is the variety of ways in which coefficient of friction (CoF) affects overall system performance and how overlooking this simple film spec and have effects on the performance of your operation.

Before we break down specific solutions to help solve for lesser-than-ideal CoF film specs, let's break down what coefficient of friction is why it matters for VFFS packaging operations.

The coefficient of friction is the “ratio of the frictional force resisting the motion of two surfaces in contact to the normal force pressing the two surfaces together”, as defined by Encyclopaedia Britannica .

There are two different kinds of friction at play when two surfaces are in contact- static friction and kinetic friction. Static friction is the friction between two objects that keeps the objects at rest- like sitting a heavy object on a sloped surface - high static friction will keep it in place.

To move the object the static friction between these objects must be overcome and kinetic friction takes over. Kinetic friction is the friction occurring between two objects that are moving relative to each other.

The coefficient of friction of your film plays a huge part in the success (or potential issues) of your packing operations, especially for vertical form fill seal machines. It’s important that VFFS packaging film have a very low coefficient of friction so the film creates as little resistance as possible when traveling through all of the rollers of the film carriage and over the forming collar.

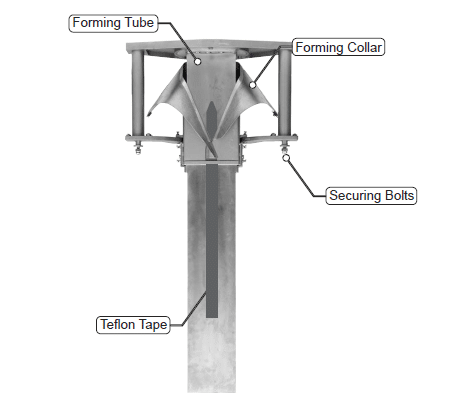

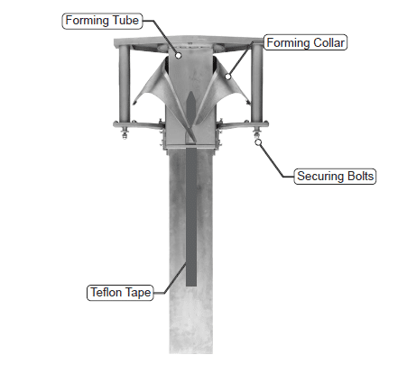

When the film comes over the forming collar, it makes over a 90-degree direction change, which has the potential to generate higher kinetic friction. This friction can put stress on the film, causing wrinkling, or in the worse cases, tearing of the film material.

Determining whether the issues with your VFFS machine are caused by the coefficient of friction (CoF) of your film can be quite challenging. However, there are several signs and indicators that can help you identify if CoF is the culprit.

A film with a high coefficient of friction can cause excessive tension as it moves through the machine. This tension can lead to misalignment, film stretching, or even tearing during the forming and sealing process. On the other hand, a low COF might result in insufficient tension, leading to slack and poor film tracking, which can cause wrinkles and improper seals.

The coefficient of friction directly impacts the consistency of the sealing process. A high COF might cause the film to stick to the sealing jaws, resulting in inconsistent seals or even damage to the film. Conversely, a film with an optimal COF will move smoothly through the sealing station, ensuring consistent, high-quality seals without compromising the film integrity.

Increased friction not only affects the film but also puts additional strain on the VFFS machine components. Over time, this added friction can lead to accelerated wear and tear on parts such as rollers, belts, and sealing jaws, increasing maintenance costs and potentially leading to unexpected downtime.

The COF of the film directly correlates with the operational speed of your VFFS machine. Films with a high COF can slow down production as the machine compensates for the increased resistance. Conversely, films with a lower, more controlled COF allow for faster and smoother operations, maximizing production efficiency.

To accurately determine if the CoF of your film is causing issues with your VFFS machine, it is advisable to consult your machinery vendor or film supplier. They have the expertise and knowledge to test film samples and provide recommendations based on their findings. They can assess the CoF of the film and suggest alternative materials or adjustments to the machine settings to mitigate the issues.

By considering the signs and involving the expertise of your suppliers, you can effectively determine if the CoF of your film is impacting the efficiency and performance of your VFFS machine. Taking proactive measures to address the CoF-related issues will result in improved packaging operations and help you meet the demands of sustainable packaging.

Many producers today are navigating sustainable packaging demands from their retailers and customers but many of these renewable and recyclable materials can come with unique challenges like higher (even incrementally) coefficient of friction that can cause issues with output speed.

This is one of the main factors to consider when evaluating paper packaging for your products. The coefficient of friction of plastic film is much lower than paper films, so production tactics and machinery innovations are often coupled with this change to help keep OEE high.

Selecting the right film for your VFFS machine is essential to optimize performance. Here are some considerations to keep in mind:

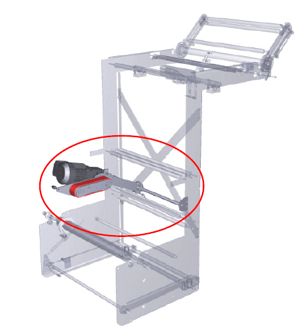

If higher friction caused by your packaging material is unavoidable, there are material handling strategies that can help to prevent wrinkling and tearing of your film caused by the added stress. Relying on just the draw-down belts below the forming collar to pull the film adds stress to the film as it travels over the collar. It’s possible to spread out the energy needed to move the film, such as using a power unwind on the back of the machine, which “pushes” the film from the back as the draw-down belts “pull”.

Not only does this help to reduce the stress on the film, but it can also have the added bonus of being able to use larger rolls of film, resulting in less downtime and labor costs.

Films with higher CoF also put higher stress on your wear parts, particularly the forming set. As I mentioned above, the edge of the forming collar can be worn down by this friction but simply reinforcing the edge can help to prolong the life of this spare part.

It's always a good idea to involve your suppliers when evaluating production changes, whether they involve your film, product doses, or changes in bag styles. Machinery vendors are often willing to test film samples for you and provide recommendations based on their findings.

ROVEMA has a comprehensive database of nearly 200 sustainable film options from multiple film suppliers, along with their testing and specification recommendations. This allows customers to transition to sustainable film efficiently and with confidence.

Machinery vendors and film suppliers often have strong relationships and truly consider themselves as your partners in business. They will work collaboratively to help you bring new packaging materials and other innovations to the market.

In the last couple of years, we have spent a lot of time unpacking sustainability as it relates to packaging- recent innovations, external...

VFFS Speed Considerations Last week we kicked off our series on VFFS speed considerations, and discussed how package width and head space relate...

Overall equipment effectiveness (OEE) is a game of inches. With the uptime of machinery having a direct impact on your bottom line, it's always an...