How the Right Snack Packaging Machine Fuels the On-the-Go Snacking Revolution

Shifting preferences in snack foods and consumer attitudes heighten the demand for packaging equipment that’s built for speed and flexibility. In...

4 min read

Emily Brogan

:

Updated on December 8, 2023

Emily Brogan

:

Updated on December 8, 2023

.png?width=443&name=rovema-ropack-flatbottom-stabilo-stand_up_pouches%20(Not%20used%20anywhere).png)

It's no secret that candy and snacks are a popular and sought-after product line. So much so, that the industry is experiencing its own innovation explosion. The pandemic has resulted in many retailers and consumers demanding different things than they used to, particularly in the confectionery space, as we saw in last week’s Sweets and Snacks Expo. Throughout the pandemic, it was reported that candy and other feel-good foods experienced a substantial jump in demand, and producers want to keep the momentum up.

In an effort to provide new experiences for customers, companies are coming up with creative ways to make their products stand out on shelves, such as experimenting with new and novel packaging, recipes, and flavors. Producers in the candy and snack space are cashing in on a year's worth of rain checks and brought their absolute A-game to this year's "Most Innovative New Product Awards".

There are 4 candy packaging trends on the rise today based on our experience at the show and in looking at the list of winning innovations. Many of these trends were already on confectioners’ radars a year and a half ago, and some are new. They range from the latest challenges of increased input costs and conversations around food safety to the long-term initiatives around sustainability and convenience.

Innovations in food packaging machines must evolve to meet the needs of the food being packaged, which of course is driven by new consumer demands. Innovate or risk going extinct - it's that simple.

So what does that mean for your candy packaging? Well, there's good news: with technology advancements over time, there have been so many more options available to manufacturers than ever before. This means that there are not only better ways to produce your current packaging but also more opportunities for you to offer consumers something new!

Innovations are driven by the needs and demands of customers, producers, and retailers as they face today's and tomorrow's challenges and call on their suppliers to rise to the challenge and find effective solutions. So how has packaging machinery adapted to specific trends in the candy industry?

The demand for stand up pouches for candy isn't slowing down anytime soon. With so many people back on the go with vacations, ball games and family events, the added convenience of shareable and recloseable packages was still a major trend at the show, as were a variety of reclosable features like zippers and Velcro.

Stand up pouches for candy can be made by a variety of different machinery types. Many folks that have a smaller production volume or a wide range of SKUs will often opt for premade packages and fill them either by hand or with a large premade pouch filling machine. The footprint of these machines is similar to a horizontal form fill seal machine, which is also a stand up pouch solution for candy. These baggers will form the pouches from rollstock and fill them as the film travels horizontally through the stages of the bagger. HFFS machines and premade pouch filling machines have very large footprints and the materials needed to manufacture them translate to a large ticket price as well.

Many of the largest candy producers are opting to manufacture their stand up pouches for candy using vertical form fill seal machines, which is a relatively new innovation that allows them to replicate doypack zipper bags but with around a 6' x 7' machine footprint.

"Clean label" formulas, plant-based or vegan formulas, or incorporating more "macro-friendly" ingredients like protein or unsaturated plant-based fats were among many of the "better for you" formulas that we have seen making waves in the candy aisle. Many choices fall into two categories: fun flavors with better nutritional profiles OR whole food ingredients and classic combinations with "clean" and simple ingredient lists - these often include foods with complex carbohydrates.

Premium and innovative candy packaging technologies are often needed to meet the shelf-life requirements of these high-value products. If you are a candy producer that is investing in higher-priced ingredients for these types of products, compromising on seal integrity or a high rate of scrap is detrimental to the success of these new product launches, particularly with the cost pressures of today's increasing ingredient costs.

Today's package sealing technology has evolved greatly to meet the quality needs of premium candy and snack products- without compromising on the speed and overall equipment effectiveness.

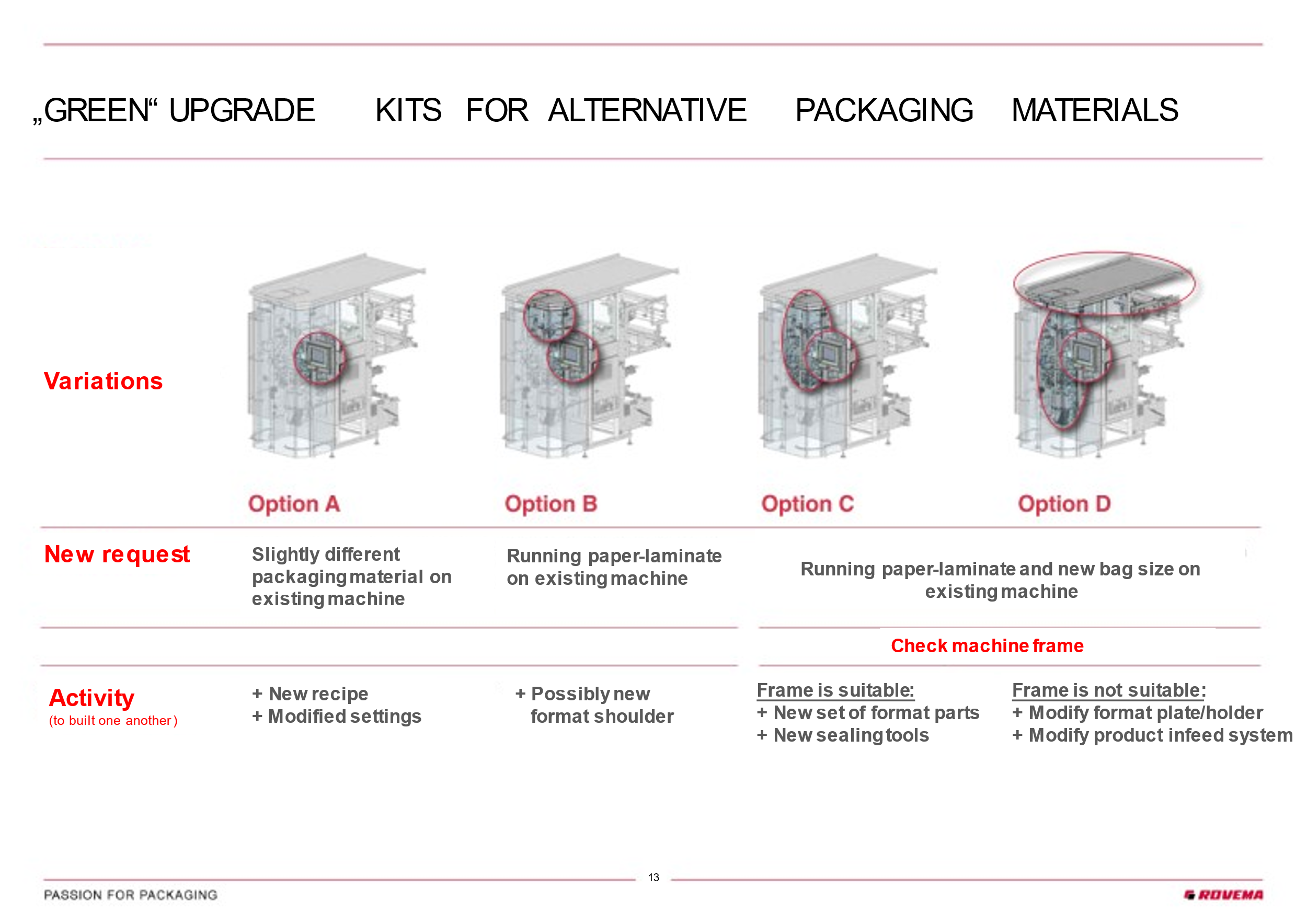

We're not at all surprised to see sustainability as another major trend; many companies feel increasing pressure from consumers and retailers to produce packaging made from sustainable materials like recycled content, soy ink, corn starch plastics and paper. Over the past few years, sustainable film technologies have scaled by leaps and bounds and as availability and demand have grown, many large brands have found it feasible to make the jump, due to lower production costs and increased awareness.

The key to a successful sustainable packaging strategy, like many of the other trends above, often lays in the capabilities of your packaging line. Sustainable packaging like paper, recyclable or compostable films can be significantly harder to handle. Having machinery with the proper film handling and sealing technology can allow you to make the jump and spare you heartburn.

We've heard a lot of concerns from the market and from our own customers around rising input costs for suppliers in general, but how does that translate into candy? Think, for example, about labor. Labor cost and supply varies greatly by region or country, so even if sugar prices stay relatively stable compared to other commodities like lumber, labor costs may still rise with the cost of living increases and general food inflation. This is what makes it hard to predict what will happen in terms of product innovation- manufacturers are always looking for ways to reduce inputs (especially costly ingredients) without impacting product quality.

A major push by producers is looking for opportunities to use less packaging materials, whether it's simply finding incremental reductions in your flexible packaging or even switching from rigid packaging to flexible. Another way that producers are looking to reduce overhead costs is by increasing their plant's automation. Often, if packaging machinery is integrated properly, an entire packaging line can be controlled from one HMI and one operator can run multiple packaging lines. We've had more and more conversations with our customers over the last couple of years around automation and digitization and are looking forward to what the future holds.

It should be clear from reading through these trends that packaging plays an important role in marketing today's snack and candy innovations. Funky designs, whimsical fonts, bright colors- these all help get attention on store shelves when consumers are faced with rows of endless packages, but making sure that the packaging does its job of keeping the product safe and fresh while giving the consumer and great experience with your product is also key to keeping them coming back for more.

Increasing input costs, demands from retailers, and pressure to continuously innovate can make things tough for many candy manufacturers, but we're proud to see that innovative candy packaging is supporting major industry trends as demonstrated at last week's sweets and snacks expo.

Shifting preferences in snack foods and consumer attitudes heighten the demand for packaging equipment that’s built for speed and flexibility. In...

Supermarket shelves have seen radical changes in the last few decades. Not only has the packaging artwork style changed and package styles become...

Sustainable packaging materials are becoming increasingly popular, and many of today’s CPG brand teams and other stakeholders are evaluating ...