3 min read

Optimizing Flexible Package Stability: Sustainable Film Initiatives

Emily Brogan

:

Updated on October 30, 2025

Emily Brogan

:

Updated on October 30, 2025

That inner swell of pride you get when you pass by your own products in the market is very familiar to me. My dad has worked for the same CPG company for over 30 years and as far back as I can remember, we would walk down the grocery store aisle as he pointed out what packages we needed to straighten up, which of their products were new and tell me stories of his time as the distributor, before he finished college and traded his box truck for an office.

That inner swell of pride you get when you pass by your own products in the market is very familiar to me. My dad has worked for the same CPG company for over 30 years and as far back as I can remember, we would walk down the grocery store aisle as he pointed out what packages we needed to straighten up, which of their products were new and tell me stories of his time as the distributor, before he finished college and traded his box truck for an office.

Today, I experience that same sense of pride when I see our own customers' products in the market and now I get to walk him to other parts of the same grocery store if we happen to go together.

Brand owners, operations engineers, and their vendor partners beam with pride when see their products stand out in the market- and more importantly, so do consumers. The shelf presence of your products matters, even subconsciously, as shoppers make quick decisions.

The Challenge of Sustainability Demands:

But here's a reality that many food producers are facing:

Big retailers and their customers are prioritizing sustainability and demanding that their vendors do the same. And many have put deadlines behind those demands.

A lot of folks immediately see recyclability as their singular solution but if you're packing product into any type of pouch today and your product requires some barrier properties of your film to stay fresh, you're probably using a premium multilayer film made of different materials like PE, aluminum, an inside sealant layer, etc.

The intricate mix of materials along with the current recycling capabilities boil down to a simple fact: the packaging for your product isn't recyclable- yet. This is the status quo here in the U.S. for many industries- coffee, potato chips, even your pet's food.

The most sustainable goal you can have for your products is to keep it as fresh for as long as possible so that it ultimately gets consumed.

Step One: Package Material Reduction

The economic accessibility of fully recyclable films with these same barrier properties is improving but in the meantime, many producers have another option- material reduction.

Here's a new resource on how to audit your package for material reduction opportunities.

Thinner films present one of the largest opportunities for material reduction. However, for producers with simpler packages, achieving stability with thinner films poses a unique challenge.

Maintaining Package Stand-Up Ability with Thinner Films

Shelf presence and package "stand-up ability" are vital factors. As films become thinner and procurement and finance departments seek greater cost savings, you may wonder how to maintain a dynamic shelf presence. The solution lies in being strategic and innovative with bag styles.

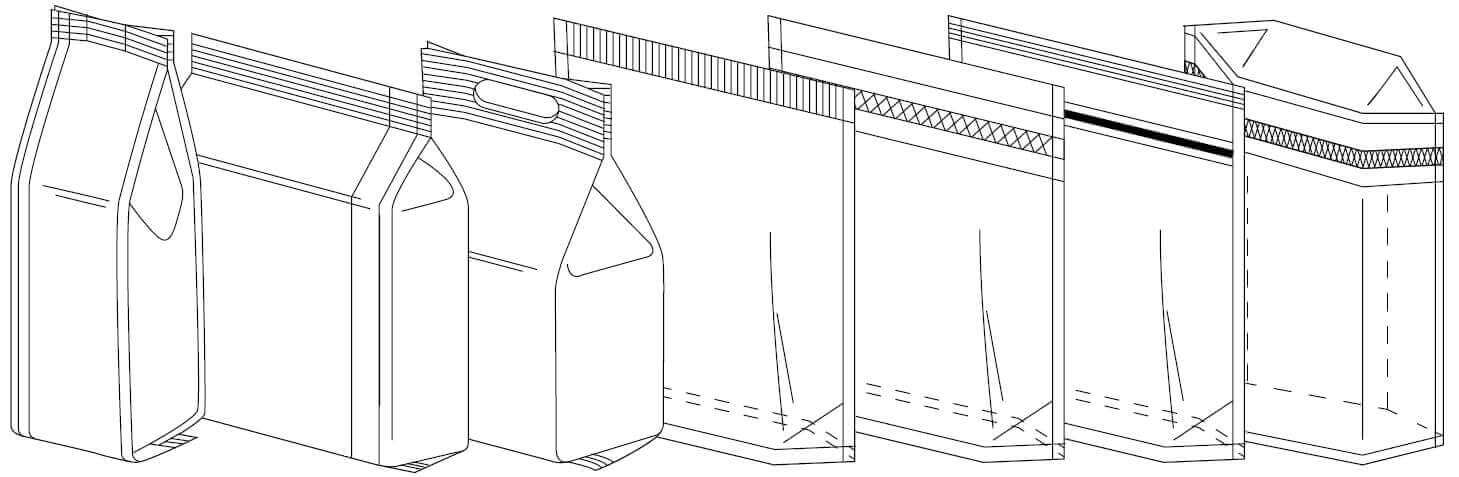

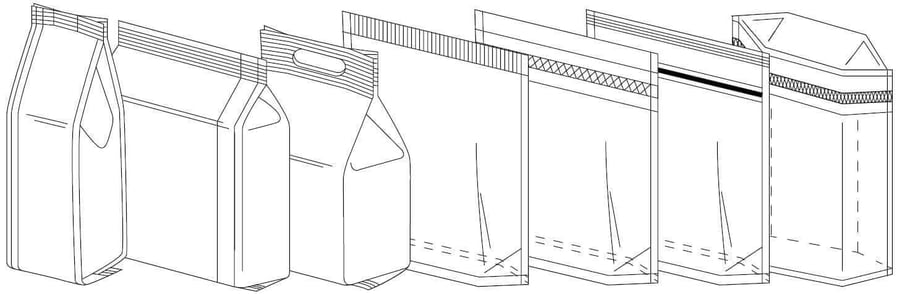

There are several bag styles engineered specifically to stand out in the market while providing structural stability, even with the thinnest of films. Let's explore a few examples:

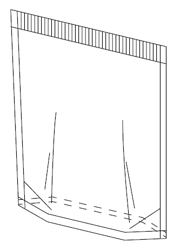

RoPack®

RoPack®

The RoPack® package is ROVEMA's trademarked version of a doy style pouch made on a VFFS machine. The seals that support the bottom of the package allow for excellent shelf presence and stand up ability and are a great fit for snack foods, powders and confectionery products and was recently recognized by one of our customers for it's innovative design.

Learn more about the RoPack bag here.

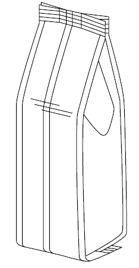

Stabilo®

Stabilo®

A patented process by ROVEMA, the Stabilo® package takes a standard block bottom bag design but adds quad vertical seals to the corners to give excellent shelf stability as well. This is commonly seen in the coffee aisle and for snack foods as well in larger sizes.

Learn more about the Stabilo bag here.

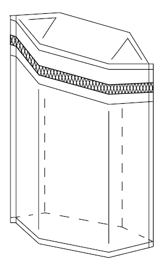

FlexCan

FlexCan

This package is formed using the same process as the Stabilo® bag and was invented to serve as a flexible alternative to cans, jars or other rigid packaging typically used for snack foods. Much like the RoPack®, the stability seals along the bottom of the package allow for a completely level and supported foundation.

All of these package types use narrow vertical seals (in addition to where the package is actually sealed) that have been great solutions for many of our customers that have converted to lower gauge films.

To learn more about different bag styles, their advances and considerations, you can check out our newest guide on current bag style capabilities, their unique advantages and considerations and the market trends driving today's innovations.

In Conclusion:

By leveraging innovative bag styles, you can enhance package stability, achieve standout shelf presence, and meet sustainability goals even while working with thinner films. While fully recyclable films with barrier properties are on the horizon, strategic material reduction and embracing bag style advancements pave the way toward a more sustainable future for packaging.

Extra, Extra! Packaging and Food In The News | October 2020

Cultivated hot list of videos, articles and other great resources that we enjoyed over the month. Sustainable Packaging Innovation: Apeel ...

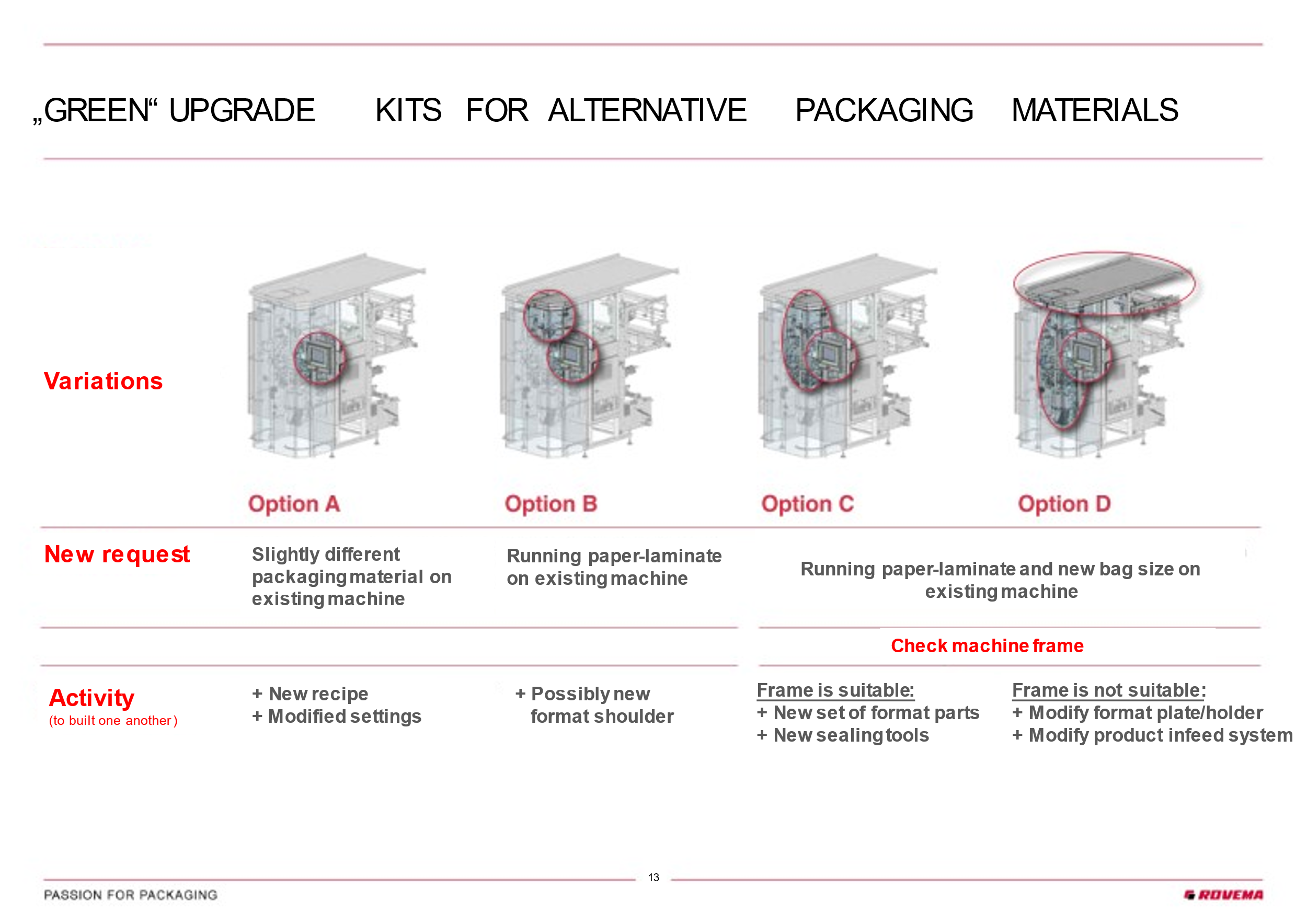

Evaluating Existing VFFS Machines for Sustainable Films

Sustainable packaging materials are becoming increasingly popular, and many of today’s CPG brand teams and other stakeholders are evaluating ...