4 min read

How the Right Snack Packaging Machine Fuels the On-the-Go Snacking Revolution

Emily Brogan

:

Updated on August 22, 2024

Emily Brogan

:

Updated on August 22, 2024

Shifting preferences in snack foods and consumer attitudes heighten the demand for packaging equipment that’s built for speed and flexibility.

In today's fast-paced world, consumers demand convenience in every aspect of their lives, including their snacking habits. The on-the-go snacking revolution is transforming the food industry, driving the need for efficient, reliable, and innovative snack packaging solutions. At Rovema, we understand that choosing the right snack packaging machine is crucial in meeting these evolving consumer demands and ensuring your product stands out in a crowded market. How crowded, you ask?

According to a 2022 report "Snack Food Market" published by Strait Research, Inc., the global market for snack foods is projected to reach USD 658.49 billion by 2032, driven by robust demand for functional snacks, and rising popularity of protein-fortified, organic and natural ingredients-based snack foods, such as bars, chips and cookies.

Sizing Up Snack Food Segments

Sweet snacks are a perennial mainstay however savory snacks are also booming, thanks to the ongoing consumer penchant for health and wellness, and industry projections from Straits Research expect the segment to grow at a CAGR of 2.90% over the forecasted period.

Sweet snacks are a perennial mainstay however savory snacks are also booming, thanks to the ongoing consumer penchant for health and wellness, and industry projections from Straits Research expect the segment to grow at a CAGR of 2.90% over the forecasted period.

From a retail perspective, categories don’t get much bigger than salty snacks like jerkies and chips, which was valued at USD 250.5 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 4.9% from 2022 to 2030 according to projections from Grandview Research, outlined in their Savory Snacks Market Size, Share & Trends Analysis Report.

Snacking Occasions

We’ve officially entered a modern era of snack eating, with 71% of consumers snacking multiple times throughout the day, according to the fourth annual State of Snacking™ from Mondelez. This further illustrates how essential snacking is to the American diet. Snacking is an essential component in most Americans’ daily eating habits .

According to Mondelez, "consumers are increasingly replacing meals with snacks, with 55 percent reporting a higher likelihood to eat a snack across all three standard mealtimes."

The rise of the on-the-go snacking trend is fueled by busy lifestyles, health-conscious choices, and the need for quick energy boosts throughout the day. Consumers are no longer satisfied with traditional meal times; they want snacks that are portable, easy to open, and maintain freshness. This shift in consumer behavior presents both challenges and opportunities for food manufacturers.

To capitalize on this trend, food manufacturers must invest in the right snack packaging machine that can handle a variety of packaging formats, ensure product integrity, and maintain efficiency on the production line.

Key Features of an Ideal Snack Packaging Machine

Versatility in Packaging Formats

The ideal snack packaging machine should accommodate a wide range of packaging formats, from single servings to larger resealable formats that can be passed around a family on the go. This versatility allows manufacturers to cater to diverse consumer preferences, whether they seek portion control, easy portability, or sustainable packaging options.

High-Speed Efficiency

In the competitive snack industry, speed is of the essence. A high-performance snack packaging machine should not only operate at high speeds but also maintain consistent package quality. This ensures that manufacturers can meet market demand without compromising on the integrity of the product inside.

Product Freshness and Integrity

Packaging plays a critical role in preserving the freshness and quality of snacks. The right snack packaging machine should include features like controlled atmosphere packaging (CAP) or modified atmosphere packaging (MAP) to extend shelf life and maintain product integrity, ensuring consumers enjoy the snack as it was intended.

Ease of Use and Maintenance

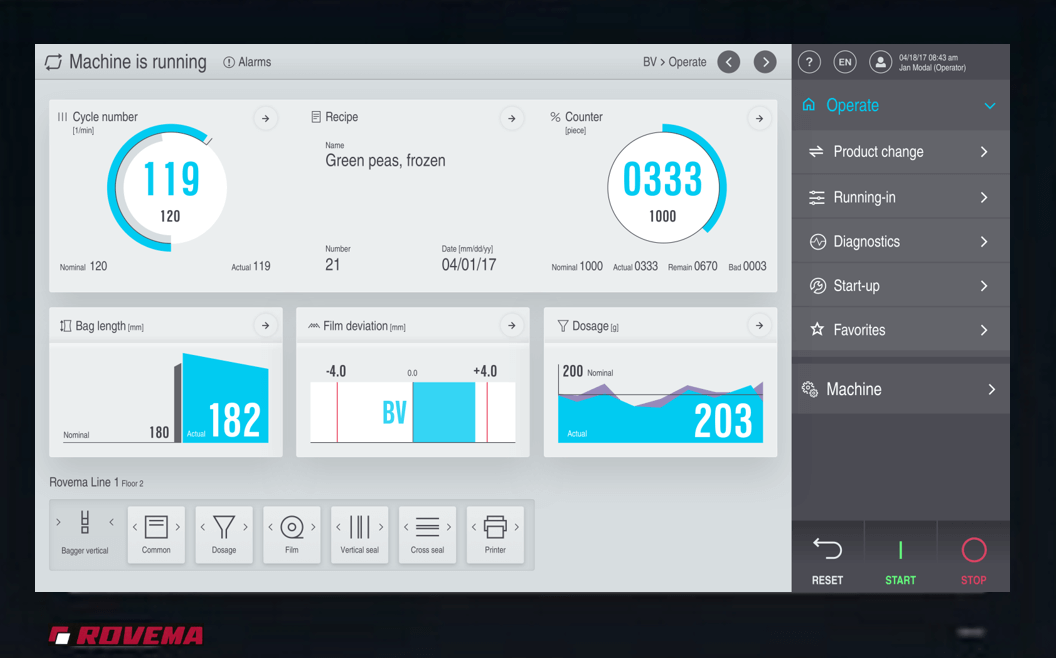

Efficiency on the production floor is directly related to how user-friendly and robust the equipment is. A snack packaging machine that is easy to operate and maintain reduces downtime and increases overall productivity. Rovema’s machines and aftermarket support programs are designed with operators in mind, ensuring seamless integration into your existing production line.

Sustainability Considerations

As consumers become more environmentally conscious, the demand for sustainable packaging solutions continues to grow. The right snack packaging machine should support the use of eco-friendly materials and reduce material waste, aligning your brand with the values of today’s consumers.

Snack Packaging Machine Solutions

Changing dietary habits are driving changing snack packaging and production considerations. That's in turn driving changing expectations of vertical form fill seal machinery commonly used for snack packaging of chips, nuts, dried fruit, jerky, savory snacks and more.

Changing dietary habits are driving changing snack packaging and production considerations. That's in turn driving changing expectations of vertical form fill seal machinery commonly used for snack packaging of chips, nuts, dried fruit, jerky, savory snacks and more.

Meeting tight production demands for snacks hinges on equipment that’s designed for speed, efficiency and simplicity. Those were the key considerations behind Rovema’s Family of BVC Packaging Systems, ultra-hygienic, continuous motion vertical baggers for forming, filling and sealing that are excellent VFFS solutions for snack product packaging.

If your operation would benefit from maximum flexibility, the BVC Flex VFFS machine can toolessly change between 13 different bag styles like pillow bags and sachets and sophisticated bag styles like the doy-style stand up pouch.

If you have a need for speed, and getting the most output out of your floorspace, the BVC Twin Tube VFFS machine could be the best fit for your operation, with a maximum mechanical speed of 500 pillow bags per minute. The twin machine is a great fit for small profiles like fruit snacks, gummy candy, and nuts.

Whatever your needs are, our snack packaging machines are designed to handle a variety of snack types, from candy and nuts to marshmallows and dried fruit. With advanced features like ultrasonic sealing, ultrasonic edge control, and product detection in the seal jaws, our machines ensure that your snacks are packaged with care, retaining their flavor and texture until they reach the consumer.

The ROI of Investing in the Right Snack Packaging Machine

Investing in the right snack packaging machine is not just about meeting current market demands—it's about future-proofing your production line. The efficiency, flexibility, and reliability of Rovema’s snack packaging machines translate to lower operational costs, reduced waste, and increased production capacity. This means a faster return on investment and the ability to scale your operations as the on-the-go snacking trend continues to grow.

How Can We Help?

The on-the-go snacking revolution is here to stay, and the right snack packaging machine is key to capitalizing on this trend. At Rovema North America, we are committed to providing innovative packaging solutions that help you deliver high-quality, convenient snacks to consumers wherever they are.

By partnering with Rovema, you’re not just investing in equipment—you’re investing in the future success of your brand.

1 min read

Recloseable Options to Delight Consumers and Run Well on VFFS Machines

Editors Note: This blog was originally published in October of 2017 but has been edited and republished with additional content around this topic. ...

3 Keys to Success with Flexible Liquid Packaging on a VFFS

Picture this exasperating scenario. It’s midday and lunch rush is happening in the restaurant you manage. You go to refill the soup and notice there...