Packaging Fuels Holiday Traditions

Holiday traditions feel deeply personal – morning coffee rituals, familiar seasonal snacks, the same confections appearing on tables year after year....

7 min read

Ember Sadler

:

December 3, 2025

When your packaging operation demands reliability, speed, and consistent quality, the choice of VFFS machine becomes critical to your success. Here's everything you need to know about Rovema's BVC series and why it's trusted by leading food and consumer goods manufacturers worldwide.

The BVC series represents more than six decades of vertical form-fill-seal innovation, engineered specifically for high-volume production environments where downtime isn't an option. From snack food manufacturers running delicate potato chips to coffee roasters packaging premium beans, these machines deliver the precision and reliability that operations managers depend on.

Whether you're replacing aging equipment, adding capacity, or building a new production line, understanding how the BVC series addresses critical packaging challenges—film handling variability, seal consistency, and changeover efficiency—can mean the difference between a packaging line that supports your growth and one that limits it.

In this comprehensive guide, we'll explore the technical capabilities, real-world performance data, and application insights that make the BVC series a cornerstone of efficient packaging operations across multiple industries.

The BVC series encompasses multiple models designed for specific production requirements, from the compact BVC 180 for smaller operations to the high-capacity REVO 6000 for industrial-scale production. Each machine shares core engineering principles while offering configurations tailored to different product types and output demands.

Key Specifications Across Models:

| Model | Bag Width Range | Max Output | Film Width | Target Applications |

|---|---|---|---|---|

| BVC 180 | 80–180mm | 240 cycles/min | 400mm | Small portions, sachets |

| BVC 260 | 80–260mm | 240 cycles/min | 680mm | Standard food packages |

| BVC 400 | 120–400mm | 150 cycles/min | 850mm | Large format bags |

| REVO 6000 | 200–600mm | 80 cycles/min | 1560mm | Industrial applications |

Available Configurations:

Control System Options:

The BVC series delivers measurable performance advantages through engineering decisions that prioritize consistency over maximum theoretical speed. While some competitors focus on headline-grabbing cycle rates, Rovema's approach emphasizes sustainable, real-world efficiency.

Proven Output Performance: Real customer installations consistently achieve 85-95% OEE, significantly higher than industry averages of 65-75%. This performance gap translates directly to increased throughput and reduced cost per package.

Advanced Sealing Technology:

Product Handling Capabilities: The BVC series handles challenging products through engineering features that competitors often overlook:

Machine Reliability Metrics:

German Engineering Heritage: Every BVC machine reflects Rovema's 60+ years of packaging expertise:

The BVC series serves diverse industries, but certain applications showcase the technology's particular strengths:

Snack Food Manufacturing:

Coffee and Beverage Products:

Nutraceutical:

Production Environment Compatibility:

Modern packaging operations require seamless integration between multiple equipment types. The BVC series is engineered for compatibility rather than isolation.

Upstream Equipment Compatibility:

Downstream Integration Options:

Turnkey System Capabilities: Rovema's single-source approach eliminates integration headaches:

Existing Line Retrofit Possibilities:

Changeover Requirements and Flexibility:

Learn how turnkey packaging solutions from Rovema simplify system design and line integration.

Sustainability isn't just about materials—it's about the entire packaging process efficiency and waste reduction.

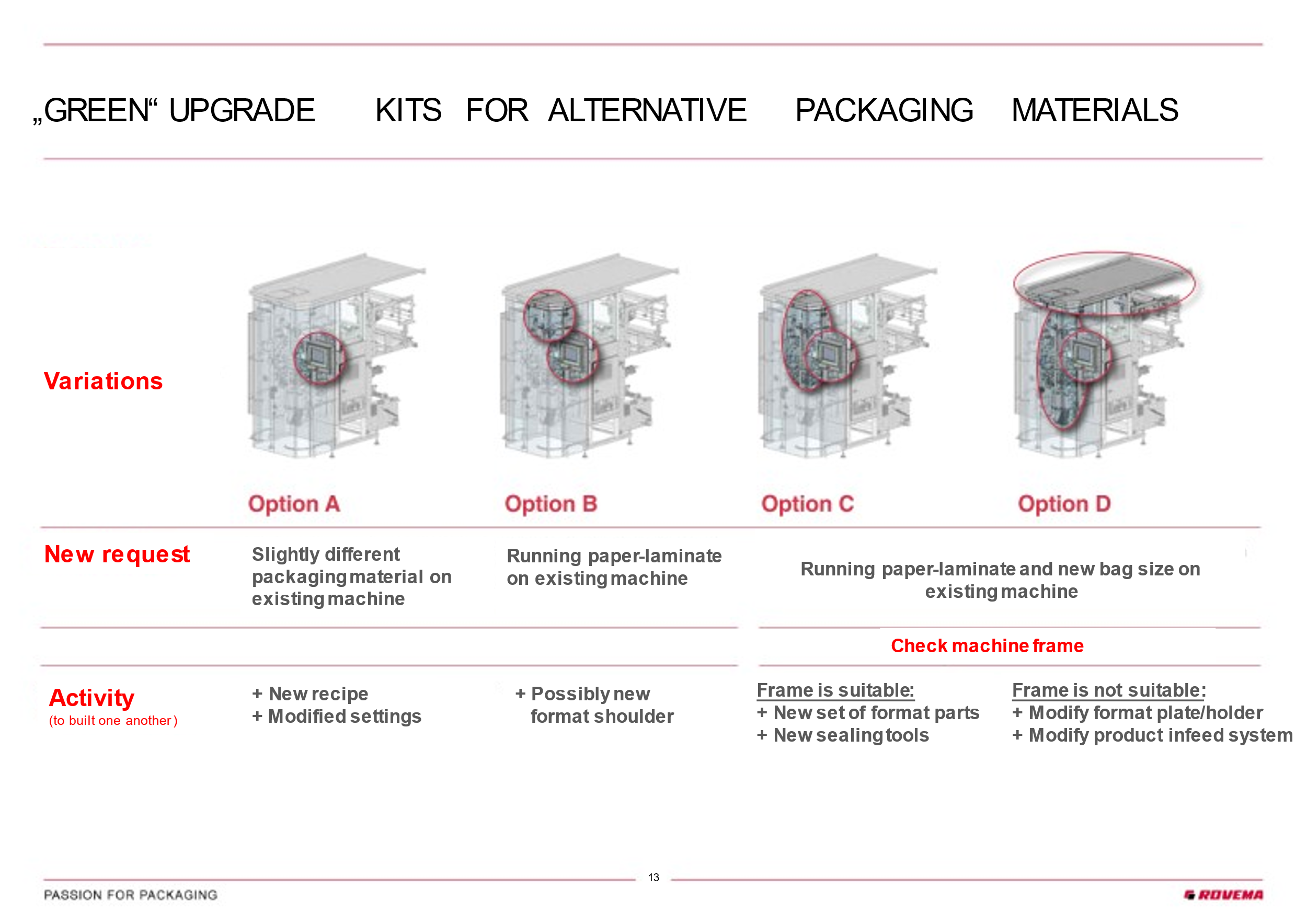

Sustainable Packaging Material Compatibility: The BVC series handles next-generation materials that traditional machines often struggle with:

Energy Efficiency and Resource Conservation:

Machine Lifecycle and Upgrade Pathways:

Waste Reduction Capabilities:

Circular Economy Contributions:

Dive deeper into Rovema’s sustainable packaging approach and real-world environmental impact.

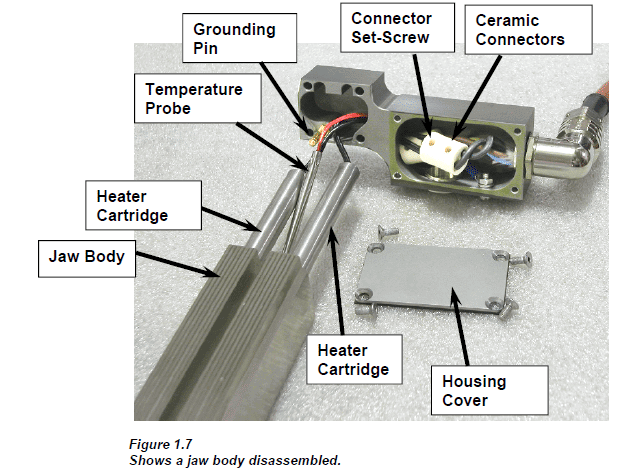

Comprehensive technical support begins with accessible documentation and continues through professional training programs.

Available Technical Resources:

Training and Support Programs:

Service Documentation:

Explore the PackPro Learning Hub for on-demand training and operator education.

Customer testimonials provide insight into actual performance improvements and operational benefits.

At Reunion Coffee Roasters in Ontario, Canada: The BVC machines helped achieve a 30% OEE increase while reducing residual oxygen levels below 2%. And, because the reliability of the machines has enabled a more accurate production forecast, “the machine operators are highly engaged and enthusiastic with the changes.” - Greg Rusciolelli, VP Operations

Quantified Results Across Customer Base:

Before/After Production Scenarios: A major snack food manufacturer replaced aging equipment with BVC 260 machines:

Common Performance Improvements:

Read the full Reunion Coffee Roasters case study for a deeper look at BVC performance in production.

Selecting the optimal BVC configuration requires understanding your specific production requirements and growth plans.

Capacity and Application Decision Matrix:

Choose BVC 180 when:

Choose BVC 260 when:

Choose BVC 400 when:

Choose REVO 6000 when:

Investment Considerations:

Competitive Advantages:

Use the VFFS Machine Comparison Matrix to compare BVC options against alternative solutions.

"What's the typical changeover time between products?" Standard changeovers take 10-15 minutes with toolless design. Complex format changes requiring different forming equipment may take 30-45 minutes. Pre-set recipes eliminate guesswork and reduce setup time.

"How does this machine handle different packaging materials?" Accommodates a wide range of film fitnesses.

"What training is required for operators?" Basic operation training takes 2-3 days. Advanced troubleshooting and maintenance training requires an additional week. Online resources and video tutorials support ongoing skill development.

"What's included in the preventive maintenance program?" Monthly maintenance requires 2-4 hours and covers lubrication, wear part inspection, and calibration checks. Annual comprehensive inspections ensure long-term reliability and performance.

"How do you ensure consistent seal quality?" Premium-Seal technology monitors sealing parameters continuously and adjusts for variations in film thickness, temperature, and humidity. Sense & Seal prevents product contamination in seal areas.

The BVC series represents proven technology backed by decades of engineering expertise and real-world performance data. Whether you're solving current packaging challenges or planning for future growth, understanding how this technology fits your specific requirements is the first step toward improved packaging efficiency.

Next Steps:

Connect With Our Team: Ready to move beyond packaging limitations? Our technical specialists understand the challenges facing packaging operations and can help you evaluate whether BVC technology aligns with your operational goals.

Schedule a consultation or call (404) 640-5310 to discuss your packaging requirements with our team.

*Planned Maintenance estimate based on single 8 hour shift 5 days/week

Holiday traditions feel deeply personal – morning coffee rituals, familiar seasonal snacks, the same confections appearing on tables year after year....

If you're hands-on with packaging machinery, you likely spend a lot of time making sure your packaging machinery stays up and running, changing wear...

Sustainable packaging materials are becoming increasingly popular, and many of today’s CPG brand teams and other stakeholders are evaluating ...