So much time goes into evaluating your bag style, choosing the right film material, and maxing out how fast you can run acceptable packages, etc.

Of course, those are crucial and excited steps to vetting out the best vffs solution for your products but at the end of the day, if your packaging solution makes it difficult to maintain an exemplary level of hygiene and safety, it won't matter what recloseable feature you picked or how fast you can run.

Food safety isn't a category you have the luxury of just glancing over, so what technologies are available for Rovema equipment that allow for consistent and efficient washdowns and changeovers?

Rovema's chemical-free automated washdown system available on our range of auger dosers allows users to reduce their downtime spent cleaning and drying the filling component by 89%. The four-step process displayed in the video above of pre-rinsing, flooding, rinsing, and drying, is automated and not only safer for your customers but your operators as well.

Even though it's chemical-free, it's advantageous as the components inside of the auger move as normal as the washing cycle happens, making sure no spot is missed.

Another auger filler feature is the high level of accessibility for your maintenance and operations teams.

Another auger filler feature is the high level of accessibility for your maintenance and operations teams.

Getting into a typical auger filler has always been a pain but for Rovema augers, they come standard with a split door hopper that opens up 180 degrees.

The hopper also comes standard with a window, allowing operators to easily monitor product levels inside.

Many common issues that producers experience with seal integrity, like the film running off-center or product getting caught in the seal, are thankfully visible to the human eye or pulled by leak detection technology.

But for some film types like metalized film, the sealing process can cause micro-leakers in the edges of the film that compromise the shelf life of the product and make for unhappy consumers.

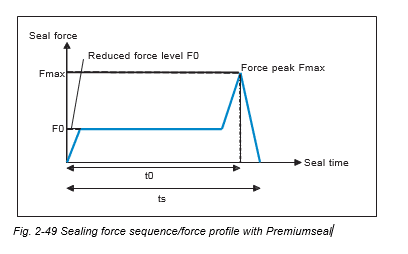

Rovema's Premium Seal ® process uses two sealing pressures in each cycle, allowing the jaws to preheat the film prior to applying full force, preventing these micro-leakers.

Rovema machine seal integrity, strength, and safety are unmatched in the VFFS industry.

When you invest capital in a project you expect the machine to perform as designed. That's a given. We've built our ongoing support program around a few simple principles:

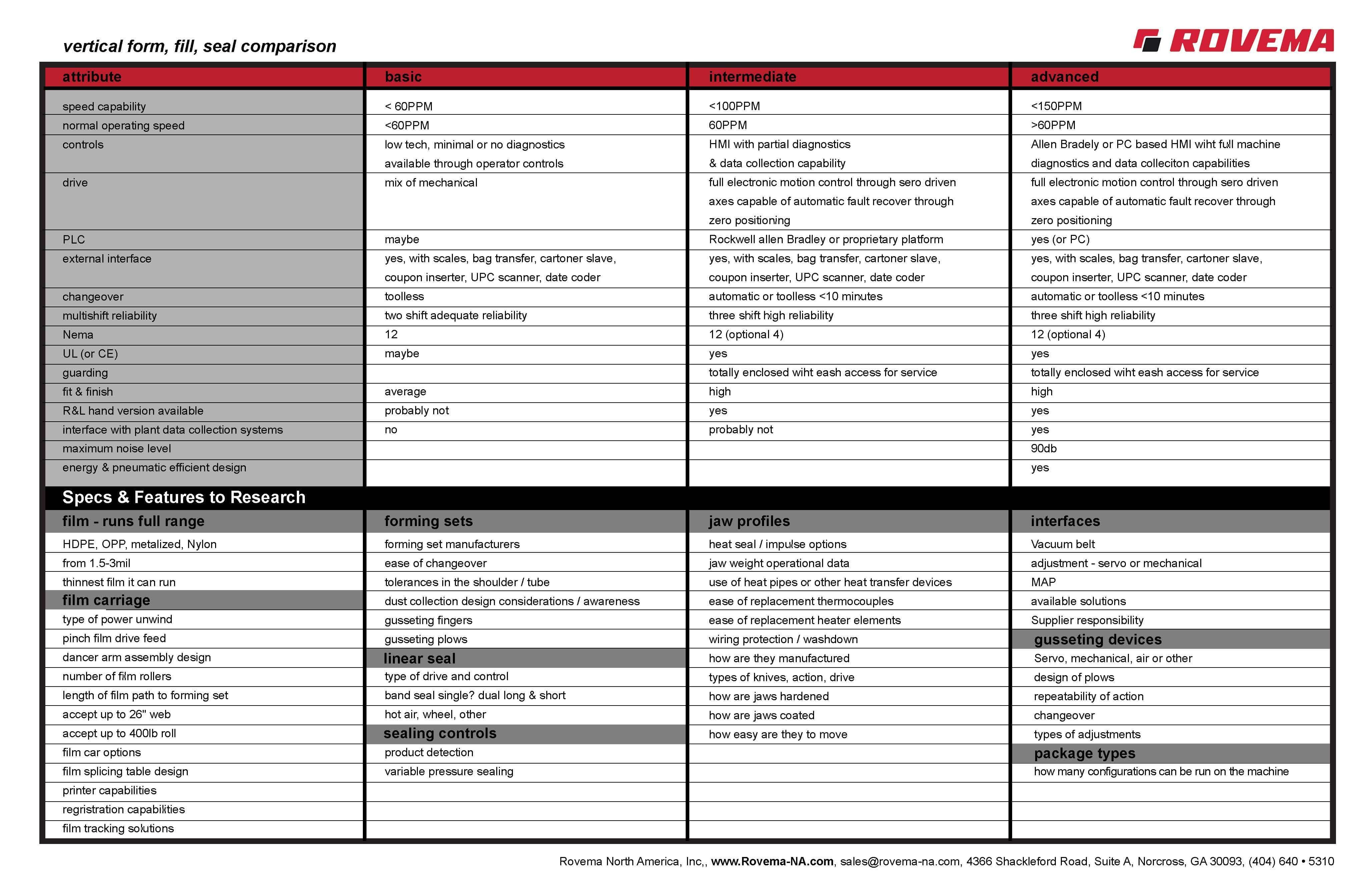

We talk about features, footprints, film drives, and food applications, but when it comes to the basics- speed, motion, controls, etc, how does Rovema compare and what other questions should I be asking?

Capital equipment involves big decisions and you need to do your due diligence to vet out the best VFFS solution for your company- even if it's not us.

We've put together a buyer's comparison worksheet that you can use to kick the tires on several vendors- and we went ahead and filled in our part for you.

.jpg?width=2483&name=BVC_145_TwinTube_CMYK%20(1).jpg)

Our VFFS machine solutions cover a wide span of product-specific model types from liquid products, frozen products, and basic products like snacks.

Other BVC models are built to maximize the flexibility of package styles or film materials with tool-less changeover from a simple pillow bag to a RoPack® doy-style stand up pouch.

They have one thing in common- they can be equipped, and often come standard regardless, with every technology above.

When your VFFS packaging line was built under a single roof in Fernwald, Germany, it wasn't built to last 10, 15 or 20 years, it was built to last a lifetime. We are intentional about making new innovations available as often as possible for older Rovema Machines.

The only time you should have to shop for a new VFFS machine, is when the new technologies are too drastic to be retrofitted to your existing one, but make purchasing a new machine worthwhile.

You can learn more about replace vs rebuild considerations here.

“Good employees that are easily accessible. Solid equipment.” - John B.

© 2024 Rovema