Brown Bag Blog Series Pt. 2: Gusseted Pillow Bag Packaging

Editors Note: This blog was originally published in May of 2021 but has been edited and republished with additional content around this topic. A...

1 min read

John Panaseny

:

Updated on December 13, 2023

John Panaseny

:

Updated on December 13, 2023

In order for efficient packaging and loading of bags into cartons for bag in box packaging, it is very important to size the bag for the carton to prevent loading jams and product damage.

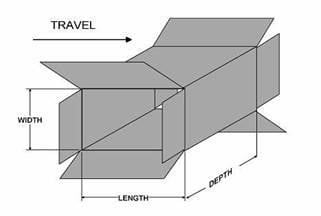

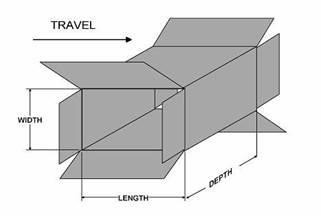

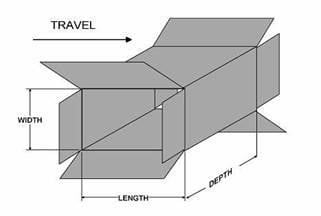

Bag girth = [(carton width + length) x 2] – ½” (12 mm)

To measure bag girth:

If the bag does not measure up properly then the vertical seal dimension and the forming set size should be checked.

Bag length = carton width + carton depth – ¼” (6 mm) See above carton drawing for dimensions

To measure bag length:

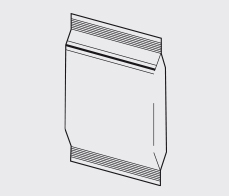

Once the bag is properly sized, then the next most important factor to check is the amount of air in the bag.

To measure the proper air in the bag:

Editors Note: This blog was originally published in May of 2021 but has been edited and republished with additional content around this topic. A...

Open your pantry. Chances are you’re going to have some product with Bag in Box Packaging. Cereal, crackers, cookies, pasta meals, and more! These...

1 min read

Bag in box packaging is a type of packaging method that uses a flexible package inside a paperboard carton. A bag in box package is created by...