Solving Bulk Powder Packaging Challenges with VFFS Machines

Dust Free Filling- Keep More Product In The Bag... Where it belongs.

Are you involved in a large-scale powder filling operation, where you pack valuable powders or free-flowing products into pre-made sacks?

Undoubtedly, you are already aware that your packaging process is quite costly, and the overhead expenses are eating into your precious profit margins.

However, finding alternative methods to accurately fill and securely seal your bulk packages is crucial. While the process may take some time, your priority lies in ensuring top-notch quality rather than mere quantity.

It is essential to prevent overfilling your large bulk powder or pet food packages, as it could result in further loss of profit.

Get More Info

Cost-effective. Fully Automated. Highly Accurate. Perfectly Safe.

Bulk powder packaging solutions have traditionally fallen into two categories: fully automated sacks from roll stock that lack accuracy, seal integrity, and package sturdiness, or partially automated methods where individuals manually fill or load empty sacks onto a premade sack filling machine.

While older automated sack filling machines may be suitable for lower-value products like soils, customers expect higher standards when it comes to their dog's food or a sack of concrete. They shouldn't have to tolerate any compromises in quality.

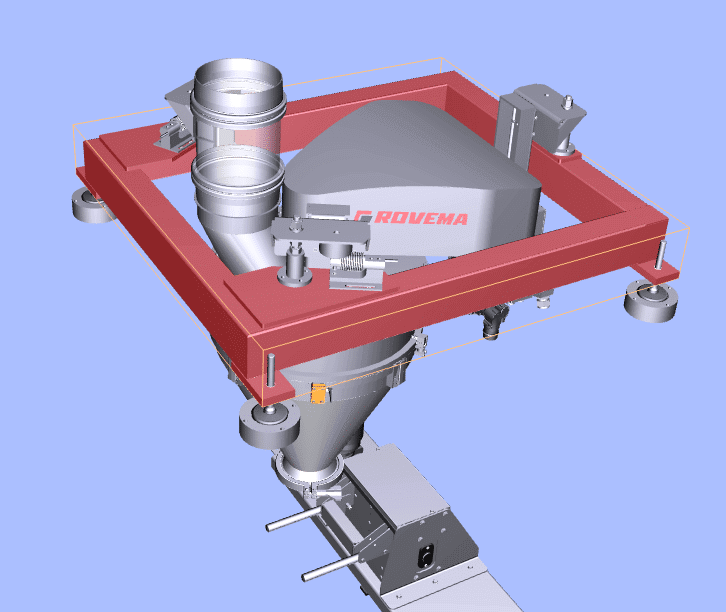

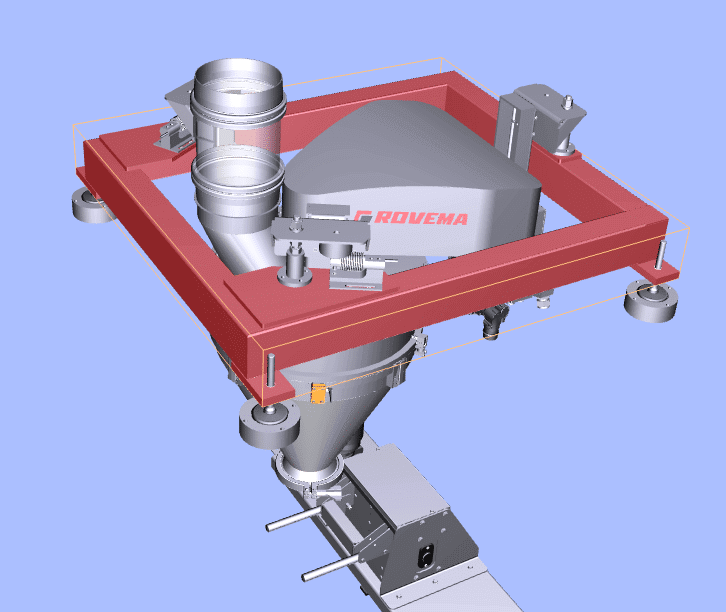

In the past, fully automated pouch forming, filling, and sealing machines were limited to small pouches weighing only a couple of pounds. However, Rovema has revolutionized the industry by expanding its reliable VFFS solutions to include bulk filling and bagging capabilities. This means that producers in various sectors, such as retail coffee or snack spaces, can now enjoy the exclusive benefits of Rovema technologies.

By embracing these advancements, manufacturers can ensure accurate filling, package strength, and seal integrity for high-value products. This eliminates the need for customers to settle for anything less than perfection.

What the SD-W Auger's Weigh Cell Technology Means For Filling Accuracy

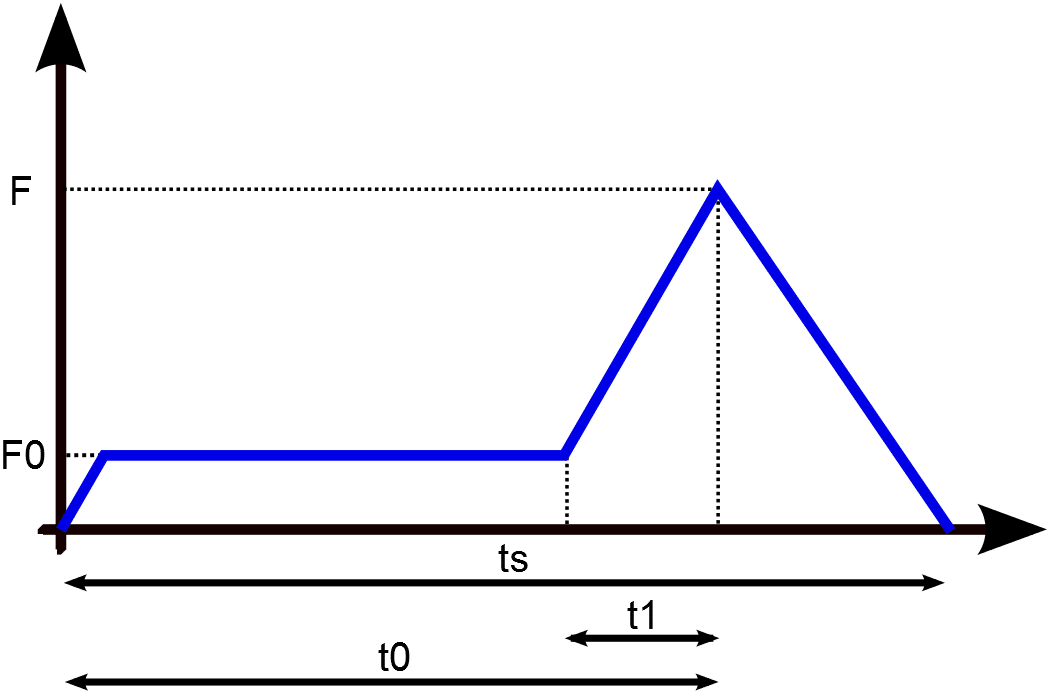

By equipping the SD-H auger filler with the standard horizontal feed screw to maintain consistent head pressure, many are able to get extremely high filling accuracy. But for extremely high-value powder products that need the highest accuracy possible, the auger can be equipped with weigh cells that trickle in the last ~5% of the product.

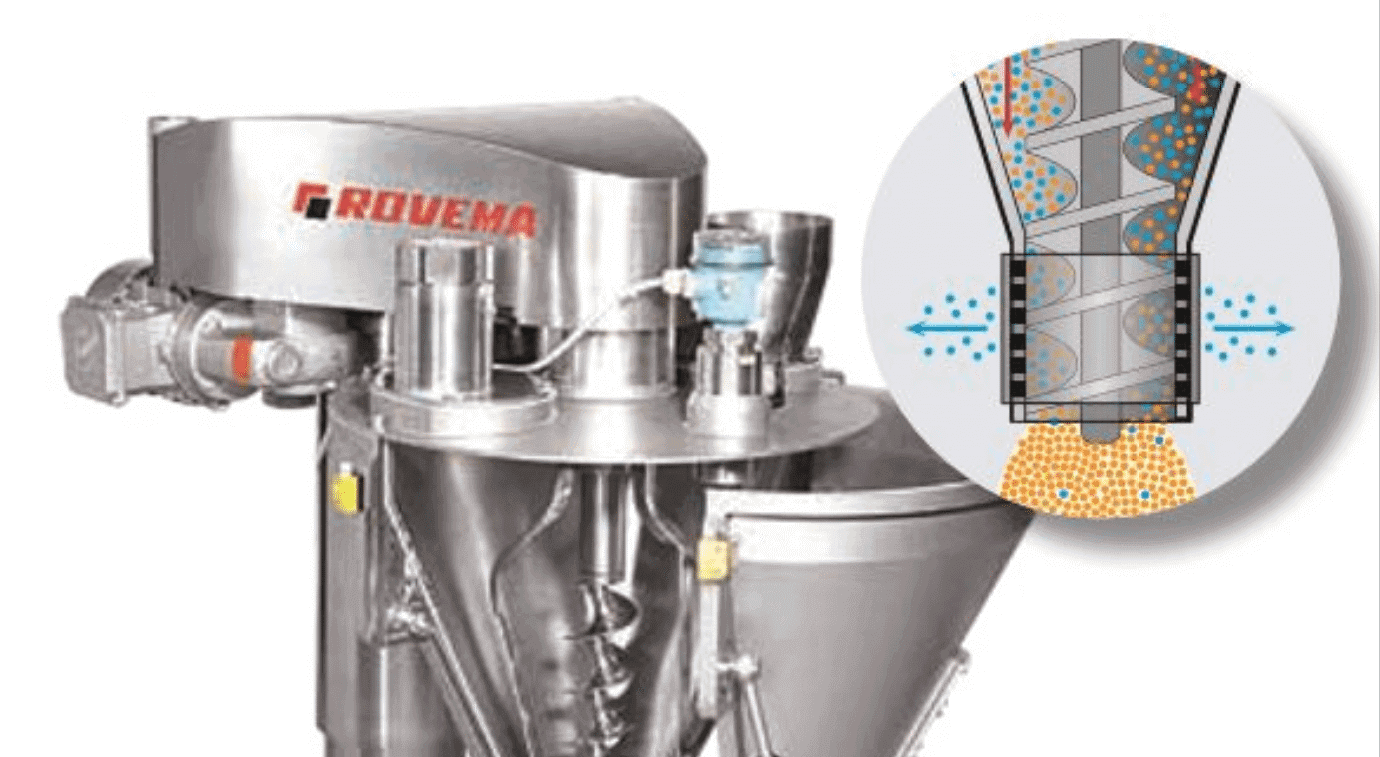

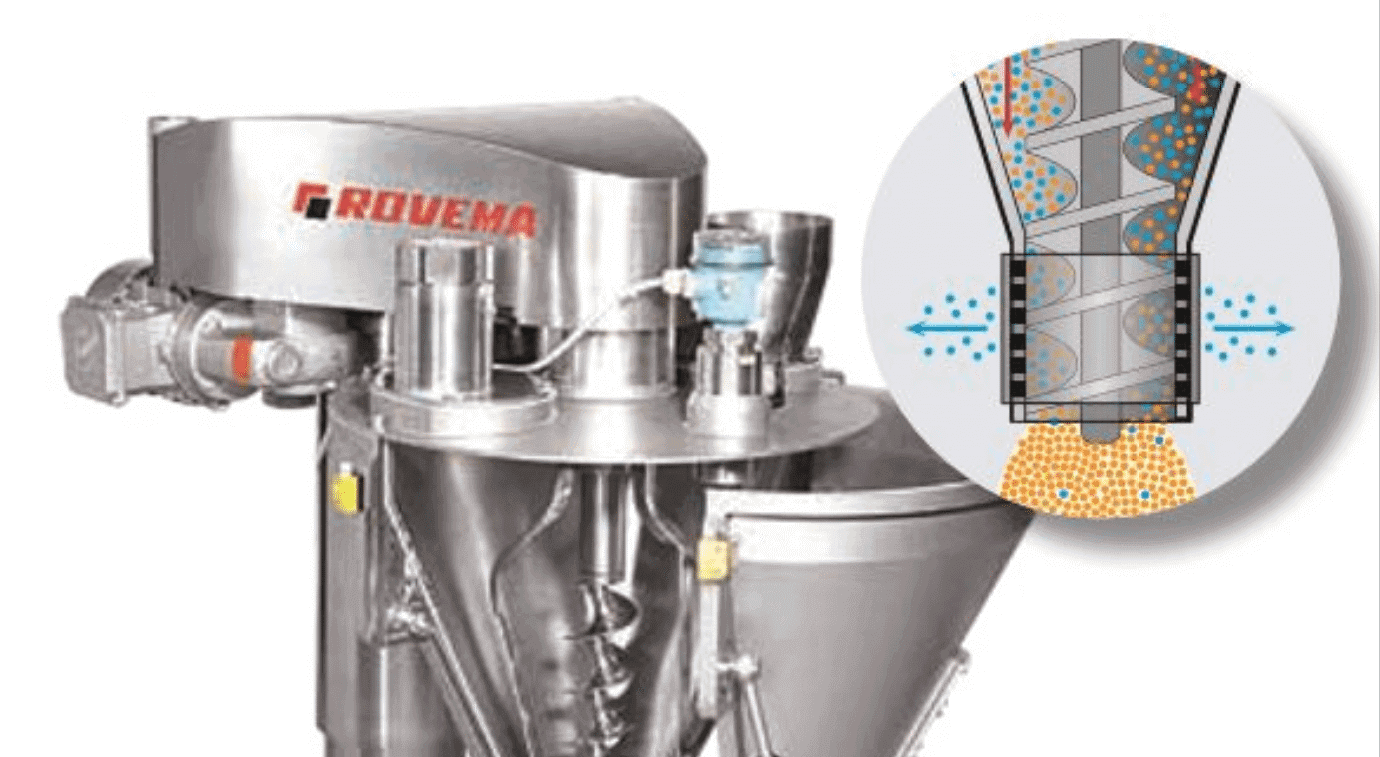

Dust-Free Solutions for Bulk Powder Filling

Dust kicked up by the packaging process of bulk dry powders is inconvenient, wasteful, and a pain. However, for some products, it can also be dangerous for the folks working in your facility, and thus, they must wear protective and expensive gear to keep themselves safe from the airborne particles.

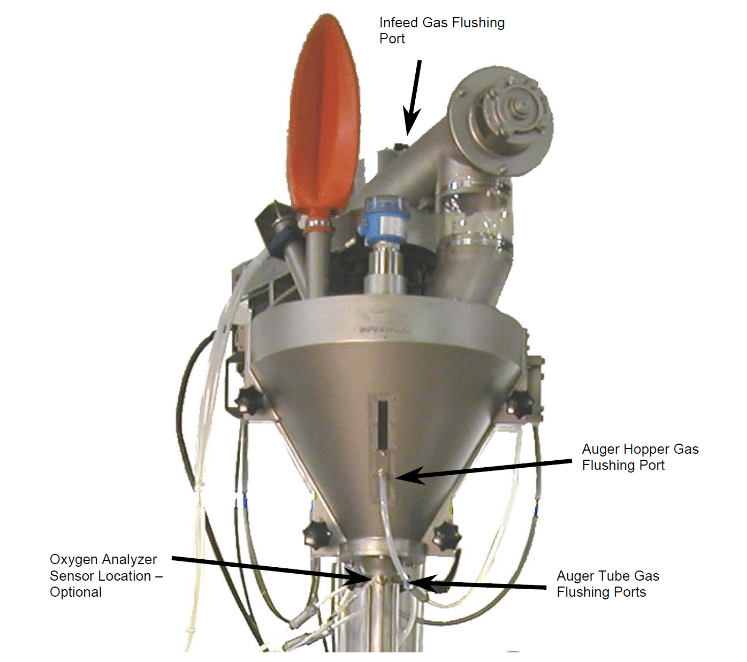

By incorporating a Rovema SD-H auger filler with vacuum dosing into your bulk packaging line, you can eliminate these issues. At the end of each dosing process, the vacuum lock prevents tiny particles from trickling down, causing them to be kicked up.

Dust-Free Solutions for Bulk Powder Filling

Dust kicked up by the packaging process of bulk dry powders is inconvenient, wasteful, and a pain. However, for some products, it can also be dangerous for the folks working in your facility, and thus, they must wear protective and expensive gear to keep themselves safe from the airborne particles.

By incorporating a Rovema SD-H auger filler with vacuum dosing into your bulk packaging line, you can eliminate these issues. At the end of each dosing process, the vacuum lock prevents tiny particles from trickling down, causing them to be kicked up.

What industries benefit?

Like it's mentioned above, there are plenty of "good enough" bag fillers and other solutions for lesser value bulk products, that from a total cost of ownership perspective, make more sense for products that fit the profile.

But if you're looking to automate your bulk packaging process for high-value products, without compromising on filling accuracy, package strength, or seal integrity, you'll have heavier factors to weigh, like cost of product giveaway, cost of product spoilage, or even your relationships with your customers.

Globally, these are the spaces we're seeing the biggest impact:

-

Pet Food Packaging

-

Construction Powder Packaging

-

Bulk Pharmaceutical Powder Packaging

-

Bulk Nutraceutical Powder Packaging

-

Carbon Black Packaging

-

Bulk Rice and Grain Packaging

Aroma Perm® Nitrogen Gas Flushing

For your high-value, oxygen-sensitive products, being able to maximize your products' shelf life by efficiently achieving less than 1% residual oxygen results in better value for your customers and retailers.

Premium Seal® Technology

Heavy sacks of product need uncompromising seal strength, or else you risk losing a tremendous amount of product. Thanks to the patented Rovema Premium Seal® technology, our seals are considered the strongest in the industry, withstanding fork truck drop tests as demonstrated in the video about Aromaperm.

Sense and Seal®

For your bulk packaging operation, every package that's formed, filled, and sealed holds a substantially higher amount of liability than many folks packaging retail stand-up pouches, for example. If you have a bad seal from a piece of kibble getting caught during the sealing process, you often don't lose just one 40lb sack of food- you lose both.

Sense and seal allows your machine to detect this, prevent it from happening, and keeps the product clean, so that it can be added back in upstream to prevent waste.

“Good employees that are easily accessible. Solid equipment.” - John B.

%20(1)-1.png)