1 min read

Un-Packing The RoPack® (Doypack) Stand Up Pouch

The Rovema Brown Bag Blog Series: The Final Chapter This blog marks the sixth and final installment of our Rovema Brown Bag Blog Series. Throughout...

3 min read

John Panaseny

:

Updated on July 18, 2025

John Panaseny

:

Updated on July 18, 2025

There are numerous reasons why someone may consider a vertical packaging machine for their coffee packaging needs. Your business may be expanding and you need to look at an option that saves on labor and packaging costs while handling the increasing demand. You may have aging equipment that is unreliable and causes excessive downtime. You may be transferring from pre-made, hand-filled bags to automated packaging looking for increased output of packaged product. You may be searching for a packaging system that has a small footprint.

Before making the decision on a vertical bagger for your coffee products there are some key points that need to be researched and considered.

The ability to package your product immediately after roasting is an important aspect of maintaining product freshness. Preventing oxygen degradation is the best way to keep your coffee tasting fresh and delicious. This is accomplished through methods, such as Aroma Perm® (Modified Atmospheric Packaging) that lowers your residual oxygen levels.

Minimum recommended oxygen levels are no more than 3%, however industry standards are typically set at 2% or less. Because the end goal is ultimately a great product that provides consumer satisfaction, a vertical packaging machine that offers low residual oxygen levels is a high priority for coffee packaging.

ROVEMA's patented Aroma Perm® Modified Atmosphere Packaging technology allows coffee producers to get below 1% residual oxygen in their ground coffee products and below 2% on whole bean products.

It may be small, but this mighty component plays a critical role in coffee packaging. During roasting, coffee beans release gases, mostly carbon dioxide, which continue to escape for days or even weeks. Without a coffee degassing valve, pressure builds up inside the bag, risking bursts or leaks.

Degassing valves allow gas to escape while keeping oxygen out, preserving freshness and protecting seal integrity. They also help shorten the time between roasting and packaging, reducing WIP inventory and accelerating throughput.

While commonly used on premium Stabilo® (Quad Seal) bags, interest in using surface-mounted “coupon” valves on high-speed coffee frac packs is rising. Ensure your VFFS machine can support valve application without compromising speed or bag quality.

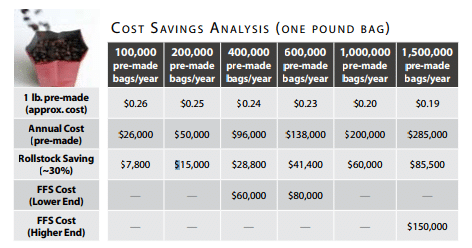

When evaluating a vertical bagger for coffee packaging, it’s not just about meeting today’s production needs. You need a system that scales with your growth. Investing in a VFFS machine that supports higher throughput and consistent uptime can deliver long-term cost savings. This is especially true when transitioning from pre-made pouches or expanding capacity. The result: faster fill rates, fewer bottlenecks, and a stronger bottom line. See the impact in the chart below:

Your package is more than a container. It’s a reflection of your brand and the value you place on your product. Often, it’s the first impression a customer gets, even before they taste what’s inside.

With bag styles like Stabilo® (Quad Seal) bags, vertical form, fill, seal machines can create sturdy, premium-looking packages that reinforce your brand image. Features such as an offset back seal align cleanly with the bag corners, leaving unobstructed panels for branding, graphics, and regulatory copy.

Regardless of the bag shape or stand up pouch style you choose, your coffee package must deliver strong, gas-tight seals and consistent form. A high-performing VFFS machine should produce visually appealing bags with excellent seal integrity, precise knife cuts, and built-in detection for any off-spec packages. That way, you can trust every bag that leaves your line.

A high-performing VFFS machine with quality components shouldn’t be a bonus, it should be the baseline. After all, high OEE (Overall Equipment Efficiency) is the goal. Reducing downtime and inefficiencies means less wasted labor and lower operational costs.

Machines that are thoughtfully engineered with reliable mechanical and electrical systems can also contribute to film savings, lower energy usage, and improved overall line efficiency. The result: reduced direct costs and a smoother, more dependable packaging operation.

Interested in how exclusive technologies can further boost your line performance? Here’s where to learn more.

Reliable support after installation is just as important as the equipment itself. Fast, knowledgeable responses to your questions help prevent costly downtime and keep your operation running smoothly. Ongoing support throughout the machine’s lifecycle ensures you're never left guessing, especially as components age and require replacement.

Backed by a responsive team of experts, you gain more than peace of mind. You maintain the performance, efficiency, and longevity your packaging line depends on.

The price of a VFFS machine (like anything) varies depending on what you want regarding performance. If your goal is high speed packaging, flexibility in packaging styles and a machine built with a sturdy and expert design, then it may be more expensive than a machine that is geared toward one bag style with lower speeds. The complexity and excellence needed of the machine correlates with the cost. For example, a machine that makes a variety of packaging styles or formats may be more expensive than one that is producing one bag format. We have a VFFS comparison matrix available that lists different performance tiers, features and other deciding factors, if this would be helpful as well.

A VFFS machine is an important part of your coffee packaging operations. You will want to feel comfortable and confident in the machine and manufacturer you choose. After all, you will have that machine for years to come. Looking at the key elements described can clarify and help make that choice easier.

1 min read

The Rovema Brown Bag Blog Series: The Final Chapter This blog marks the sixth and final installment of our Rovema Brown Bag Blog Series. Throughout...

You’ve heard the question, "If you were on an island and could only take three things, what would you bring?" It may take me a minute to come up with...

1 min read

Welcome Back: The Rovema Brown Bag Blog Series Hello hello! We hope you’re doing well. Welcome to this month’s edition of our Brown Bag Blog...