7 Things to Look for When Choosing a VFFS for Coffee Bean Packaging

There are numerous reasons why someone may consider a vertical packaging machine for their coffee packaging needs. Your business may be expanding and...

3 min read

Christa Francis

:

Updated on August 8, 2025

Christa Francis

:

Updated on August 8, 2025

You’ve heard the question, "If you were on an island and could only take three things, what would you bring?" It may take me a minute to come up with the other two items, but I don’t even need a second to give you the first one. Coffee! It’s how many of us make it through the first hour of the morning (or even half the day).

Coffee roasters take pride, and rightly so, in their roasting process and endeavor to create a product that has quality flavor, acidity, body, aroma, and finish. During the packaging process of coffee, both volatile and non-volatile gases are released. These gases, 80% of which is CO2, add to the flavor of the coffee but also continue to emit for some time. This is why, when perfecting the roasting process, the packaging process of coffee is not just the final step, but an extremely important one. Flexible coffee packaging maintains the freshness, integrity, and shelf-life of the ground or whole bean coffee, and it does so in a way that is unique compared to other products packaged on a vertical bagger.

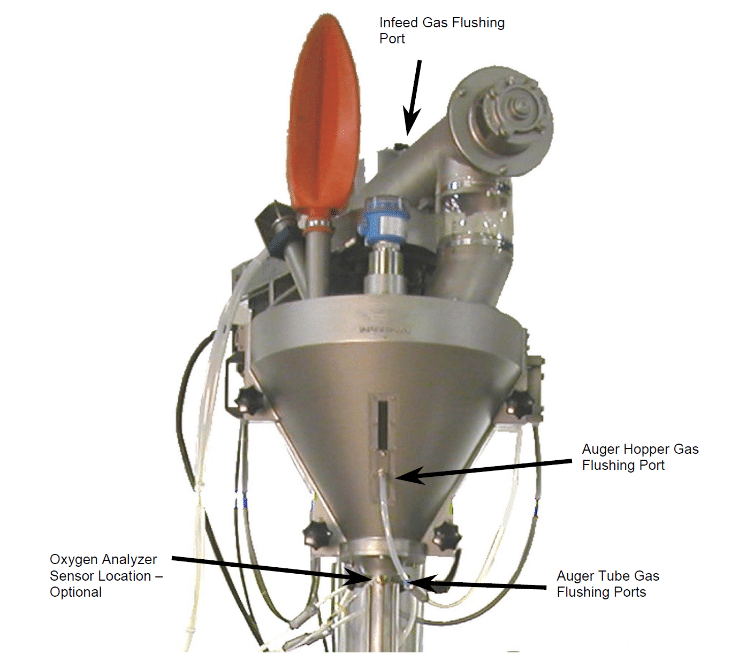

Gas flushing, either by Aroma Perm® or modified atmosphere packaging (MAP), and a one way degassing valve are necessary for maintaining freshness, an important aspect of coffee rating. Gas flushing replaces oxygen, a component that quickly decreases shelf life and quality, with nitrogen. With the minimum recommendation of a 3% residual oxygen level (many roasters require a lower percentage), gas flushing is an imperative feature.

While gas flushing is one feature that makes the packaging process of coffee different, the one-way degassing valve is equally as distinct and essential. It is incorporated into the bag-making process at the end of the unwind and prior to the forming stage and can be placed in various areas on the pouch. Let’s look at how this small, button-like feature is integral to flexible packaging solutions on a VFFS.

1) Inflation! And I am not referring to pricing and the economy, but to inflation that occurs in the packaged coffee as a result of gases being released. The emission of gases begins just after roasting. Giorgio Olmi explains:

“Retaining these gases inside the package may be dangerous, as it may cause package inflation with consequent failure. Moreover, inflated packages may also roll over the shelf and then drop down to the floor.”

With the pressure continuously building as a result of these gases, the bag could swell, leak, or even burst open. The degassing valve allows these gases to escape the pouch during storage, causing more flexibility with the package, maintaining package appearance, and preventing a messy cleanup due to a bursting bag.

2) Oxidation. This is defined as a chemical reaction where a material loses electrons, which happens when the material combines with oxygen. While oxygen allows us to breathe and live, it is also an eroding, corrosive factor. Think of rust or an apple that has been cut and then starts to brown. These are the results of oxidation occurring.

What does oxidation mean for the freshly roasted coffee? It is the main factor in causing the coffee to become stale and decreasing shelf life. It can mean the difference between a high-quality shelf life of 10 days or four months. Ground coffee is even more susceptible to this than whole bean.

As discussed, the prevention of oxidation is generally referred to in terms of gas flushing and its role in replacing oxygen with nitrogen. The one-way degassing valve plays its part as well. It prevents the oxygen from coming in while at the same time releasing the other gas emissions from the ground or whole bean coffee.

3) WIP (Work in Process) Inventory. With the degassing valve, roasted coffee can be packaged quickly. As mentioned, CO2 is released from coffee immediately after roasting. With ground coffee in particular, a third of CO2 is released immediately and an additional third of the gas is released within the next 40 minutes.

Without using a degassing valve, transitioning from roasting to packaging would be more time-consuming. This can be especially true if using a bin degassing method versus gas flushing and packaging with a one way degassing valve. If it is immediately packaged without the key valve component, you have the inflation and risk of a leaking pouch. The catch 22 of that is if it is not immediately packaged, there is more oxidation. The delay in the packaging process of coffee means the product does not get to go directly to market and therefore, is held in WIP inventory.

When using VFFS machines, these valves are an integral part of coffee packaging. The fractional (frac) pack, which does not typically incorporate a degassing valve, is starting to incorporate the label style valve into the pillow bag design, to allow the same high-speed coffee packaging solution that producers are using for their standard one pound stand up pouches.

Let’s give these tiny coffee valves a round of applause for the work they do to make our coffee delicious. This simple mechanism allows the accruing build-up of gas to be released from a sealed container while preventing oxygen from coming into the bag. It not only allows for freshness and better quality, but increases the efficiency of the packaging process, helping to provide the consumer with an enjoyable and positive experience.

There are numerous reasons why someone may consider a vertical packaging machine for their coffee packaging needs. Your business may be expanding and...

While oxygen is essential for our survival, it can be detrimental to the freshness and quality of coffee. Roasters worldwide face the challenge of...

Cultivated hot list of videos, articles and other great resources that we enjoyed over the month. Sustainable Packaging Innovation: Apeel ...