These 5 Symptoms Tell You It’s Time To Replace Your VFFS Machine

Spending some to save more Industrial operations, especially in the food industry, are all about minimizing costs, both operational and capital....

4 min read

Christa Francis

:

Updated on August 8, 2025

Christa Francis

:

Updated on August 8, 2025

For those of you concerned with maintaining optimal OEE (Overall Equipment Effectiveness) this is not only an interesting statistic but it also compliments information we receive from organizations who are interested in replacing their current vertical bagger.

But is replacing your machine with a new one the best choice? The answer is that it depends - there are options to maintain, rebuild, or replace your machine. While choosing one of these actions may seem like something that should be easy to determine, there is often analysis and research involved in making sure the choice is cost effective and right for your production plan and goals.

When choosing to repair, rebuild or replace your VFFS, the decision is often associated with cost and capabilities. For an analysis that looks at those two qualities and then goes even deeper it is important to ask the following questions:

Do they prefer new machines with new features or an aged machine?

Available funds may limit your choice of what is necessary vs. what is preferred.

It is important to use formulas comparing payments and depreciation with high operation costs. This could include information on failure rate, maintenance repair man hours and other data that impacts cost and profit.

An industry with slow growth would be more limited than a thriving industry.

A pillow bag may be fine for your product but what if adding a zipper adds a value that causes consumers to prefer your product over your competitor's? Would having the ability to produce a stand up doy style pouch on the same bagger allow you adapt to new consumer preferences?

Is there excessive downtime that prevents you from meeting production goals? Or does the bagger speed limit your production capabilities?

Now that we've focused on the above important questions to consider, let's look further into VFFS service and what it means to maintain, rebuild, or repair your machine.

When you make a decision to repair certain items in your car, this is often due to some type of wear and tear. Examples of this could be getting new tires or new breaks. This is also applicable to a vertical bagger with items such as the draw-down belt and other routine parts.

Repairing your machine is performing maintenance on an item that has failed or is defective. How often a machine may need a new part can be heavily dependent on preventative maintenance and the product itself. For example, oil would be more kind to a machine than a granular product and the VFFS would need less stringent maintenance requirements than it would with the harsher product. Sometimes it may be more effective in the long run to replace a specific system rather than the failed component.

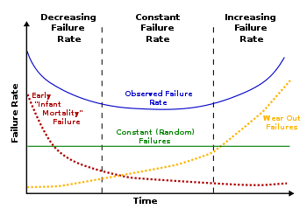

A machine typically ends up moving to the rebuild or replace decision point when repairing becomes more aggressive. A warning sign may be going from needing a new vertical seal band once every three years to every 6 months. You can repair the system by replacing the part and have it operational again, but it continues to fail at an increased rate costing more time and money.

The OEE Primer describes the stages of failure rate which leads a transition from repair and maintenance mode to the rebuild or replace mode. This three-part period, referred to as the bathtub curve, involves infant mortality failures, useful life failures, and wear-out failures.

Equipment failure, effectiveness, and reliability are typical factors that trigger this decision point. Rebuilding means you want to get as close to a new machine as possible without buying a new vertical bagger. It provides additional life to the machine and an improved quality. This is not to be confused with a machine conversion which typically involves adjusting the machine for a new bag style, feature, or upgrading equipment, although it can be related to the choice.

From a mechanical standpoint (at least this is the case with Rovema) almost any vertical bagging machine can be refurbished. This may not be applicable, however, from an electrical standpoint. An older bagger may not have the software or electrical capability to take advantage of advanced features commonly found in newer VFFS accessories.

Jim Fox, a Rovema service technician with 25 years in the industry remarks:

"We often do electrical conversion upgrades which can incorporate technological advances and thereby extend the life of a mechanically sound machine about 10 years. In some cases we might not recommend this. Particularly if the machine is more than 25 years old. However, for any machine of a VPR-250 design or later this is often a less costly solution than buying a new machine. Within the past 2 years we have actually done 6 or 7 of these upgrades to the current controls systems with great effectiveness. This typically costs about half the cost of a new machine."

Replacing a VFFS typically means accounting formulas and cost have been researched, the quality of the machine has been determined and you have decided that you need a new machine with the same capacities or one that has new features compatible with your company’s production direction.

The replaced machines can be repurposed for other production purposes. If a company has a fleet of the same machine type, the machine that was replaced can be cannibalized and used for parts. If the machine was replaced due to a need for new capabilities, the old one may be transferred to another facility where its characteristics are more applicable.

There is nothing more important to increasing the life cycle of your machine than preventative maintenance. Including scheduled repairs to your machine as part of a preventative maintenance routine is especially necessary. This is because failures and subsequent repairs have 1.5 to 2 times more cost than a scheduled maintenance repair. Maintenance and scheduled routines are specific to each machine, company, location, and product.

If your goal is cost savings, profitability and sustainability, this can be achieved by a machine that is reliable, safe, easily maintained and efficient. As your machine ages, you lose parts or all of these aspects. Knowing when to and planning for repairs, a rebuild or replacement can help your organization achieve OEE. Let us know if you have any other thoughts, suggestions, or ideas on this topic by hopping in the chat.

Spending some to save more Industrial operations, especially in the food industry, are all about minimizing costs, both operational and capital....

Packaging machinery is an important feature in managing and branding your product. Your vertical bagger should improve your OEE (Overall Equipment...

For most of us, when we decide to make a purchase, the interaction with the team that designed and produced it is short-lived. When we go to buy...