VFFS Machine Flexibility: Why It’s Critical, Especially Today

If these last few months have taught us anything, it’s that flexibility rules. Whether that’s being flexible about where and how you work (Hello,...

4 min read

Megan Reschke : Updated on December 14, 2023

.png?width=746&name=Copy%20of%20Webinar%20Cover%20Slide-%20Azo,%20Connecting%20Food%20and%20Rovema%20(1).png)

A few months back, we posted a blog about the importance of flexibility in your VFFS Machine. We discussed how important it is to have packaging machinery that not only excels within current conditions but also adapts to meet new demands that arise down the line. We analyzed how machine agility and flexibility go hand in hand and how, together, they can ensure that you are able to meet the demands of both your consumers and stakeholders.

In this blog, we’re expanding upon this topic to include a more broad analysis of the relationship between institutional and retail business.

Often, we see a whipsaw relationship between institutional and retail: one in which there are rapid transitions between upward and downward trends on either end, resulting in significant impacts to you and your products and markets. These whipsaw trends have awakened folks to the need for flexibility in their packaging machinery, and we believe that Rovema’s VFFS packaging machinery can meet this demand. Our VFFS machines are highly efficient, flexible, consistent, and customizable, and our team has the expertise needed to support your company through the ups and downs of this whipsaw relationship.

You might be wondering why we decided to devote another blog to a seemingly similar topic as our one on VFFS machine flexibility. Though there are many connections, we wanted to focus more on the complexities of the relationship between institutional and retail, and talk about how Rovema has the expertise to support you as you balance your investors’ needs with your customers’ needs.

Navigating the past year has taught us all the importance of being able to react, adapt, and embrace flexibility. This isn’t something that’s unique to the packaging world; we’ve seen this across all industries and in all professions.

It would be quite easy to spend an entire blog harping on the challenges that COVID has brought, both within the packaging industry and beyond (Toilet paper shortages! Extreme demand for shelf-stable packaged products! How to balance you and your partner needing to be on two different VERY IMPORTANT Zoom calls in the same 1-bedroom apartment at once!)

These are all things we know and are familiar with, and there’s no use wallowing in the different challenges that we’ve all faced.

As such, we’d like to focus this blog on the lessons that have been learned, how we can use the insights we’ve gained as we move forward, and how, in the packaging industry in particular, we can be better prepared to balance retail and institutional demands.

At Rovema, we believe the best way to be prepared for the whipsaw between retail and institutional is by building defensive resilience and "opportunistic optionality" into your primary and secondary packaging.

Last year, we saw rapid and extreme swings in the market. This impacted investor demands being placed on consumer goods companies. We learned that we need to be able to quickly innovate and adapt to these ever-changing needs, especially when big challenges like COVID arise.

Producers experienced huge shifts in retail product demand during COVID. Think about those first few weeks when we went into lockdown. I don’t know about you, but when I walked into the grocery store, I was met with mostly bare aisles. Beyond the toilet paper disappearing at an alarming rate, shelf-stable products went rapidly. I saw people with carts filled with granola bars, trail mix, packaged soups, and other products they knew would last a long time, and I feel pretty confident predicting that you saw something similar.

With customers scrambling to scoop up these products, a great demand was placed on companies like yours from the retail end: to package more product with increased efficiency and speed.

At Rovema, we saw that these different pressures--from both institutional and retail--resulted in a whipsaw effect for many of our customers. The mass migration of demand from the foodservice and institutional channels over to retail caused a lot of heartburn. To try to survive, companies adapted as much as their operations would allow, to convert idle foodservice capacity to aid blistering retail demand.

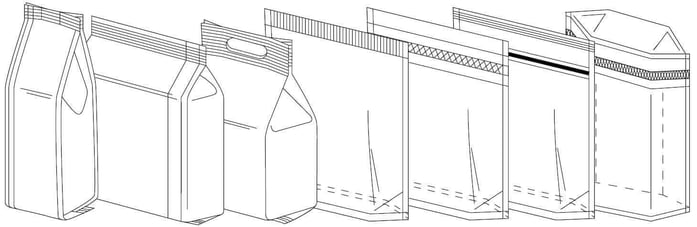

But often, food service and retail markets have different market expectations of VFFS bag style, shelf presentation, and even package size, so one-trick-pony packaging solutions siloed production lines and even entire facilities.

The big takeaway? As companies move forward, they need to build defensive resilience by investing in predictable, flexible, and efficient machinery, while also allowing for opportunistic optionality by choosing VFFS packaging machines that are customizable, agile, and flexible. Rovema understands the pressures that you are under, and we are prepared to support you by providing excellent machinery that allows you to respond to changes that come from various external forces.

Market changes have taught us that there is a great need for packaging companies to be able to both adapt AND innovate. Though many folks assume that these are mutually exclusive, they don’t need to be.

Rovema has proven expertise when it comes to engineering packaging machines that are highly agile and adaptable. We have demonstrated excellence and understanding of integrated production lines and have a stellar team devoted to helping you maintain and adapt your machine for as long as you see fit. A new need arises from retail demands? We’ve got you covered. Our machines have no end of life, showing just how far we’ll go to demonstrate our dedication to longevity and adaptability.

Many would assume that machines with this level of adaptability are rigid, one-trick ponies that lack innovation. At Rovema, this is far from the case. We are constantly on the cutting edge of new technology and innovations, like our newly-patented Collect, Buffer, Feeding Technology. We know that you have a responsibility to show your stakeholders that you are keeping up with the latest trends and innovations in the industry, and we’re committed to providing you machinery that allows for that.

Owners have responsibilities to their stakeholders, especially when it comes to planning capital investments. When considering capital equipment to invest in, it is important to consider all eventualities and all parties impacted.

Understanding the whipsaw between retail and industry and how investing in VFFS packaging machinery that is both adaptable and innovative will be hugely beneficial to your company. You need to be able to please your investors, as well as meet the demands of an ever-changing retail landscape.

We’ve all learned lessons from this last year. At Rovema, we feel that, in particular, we’ve used the challenges we’ve faced to drive us forward and help us better serve our customers. At the end of the day, we want to help you pick the best VFFS solution to meet your distinct needs.

If you’d like to chat with an expert, please reach out to us. Or, you can connect with a live person now in the chat.

If these last few months have taught us anything, it’s that flexibility rules. Whether that’s being flexible about where and how you work (Hello,...

1 min read

In Case You Missed It: the Rovema Brown Bag Blog Series Over the past few months, we’ve been creating and sharing posts as part of our Brown Bag...

1 min read

It’s intriguing to read studies about food and supermarket psychology: how milk and eggs are located far from the entrance so shoppers get...