The Secret Ingredient for Long Term VFFS Machine Reliability

For most of us, when we decide to make a purchase, the interaction with the team that designed and produced it is short-lived. When we go to buy...

4 min read

Emily Brogan

:

Updated on December 13, 2023

Emily Brogan

:

Updated on December 13, 2023

Thinking back over the last year (and then some..) on the challenges of COVID-19, it's interesting how much our priorities have changed.

On an individual level, we've gained a deeper appreciation for family, friends, and celebrations, as well as nurtured green thumbs and maybe a new pet. It's interesting to see that many fundamental priorities of the business world have changed as well. Particularly the priorities that differentiated companies that showed resilience and even success over these tumultuous times.

Over the course of conducting their survey across Europe, Africa, North America, South America, and Asia, the IEEE determined that the top 3 enablers of manufacturing resilience in 2020 were:

Organizational Flexibility

Employee Skills and Know-How

Technological Ability and Capacity

It's probably safe to make the alternative assumption that companies that struggled or even succumbed to the COVID-19 disruptions likely struggled in some or all of these categories.

A primary enabler of all three of these categories is harmonizing packaging operations across multiple plants. For example, just consider the disruption a year ago as nearly all institutional and foodservice demand took a nose-dive, as retail demand for packaged foods and other staple items surged to the point where many categories couldn’t keep up.

Entire inner grocery store aisles were left bare. The same aisles that, for years, had been giving up grocery store real estate to products on the outer perimeter or “fresh” sections in the past - these inner aisles were cleaned out as consumers prioritized foods with longer shelf lives, that were considered to be more comfort-focused.

Food manufacturers that supplied to both institutional and retail markets had serious challenges to overcome as they did what they could to shift production to meet these higher retail demands and mitigate the losses to their foodservice side of the business.

For many companies, their product types made the process simple- only needing to switch to retail SKU packaging with package styles and package sizes remaining largely the same. But for many producers, the process was not this simple.

Institutional/foodservice versus retail markets often have drastically different demands and priorities, whether it be the finished package sizes, re-closure features, and even the entire package style itself. Take the pasta industry, for example. The pasta aisle took months to keep up with the spike in retail demand and while most retail pasta facings are in 1lb cartons, pasta for food service is often packaged in flexible pillow bags up to 10lbs.

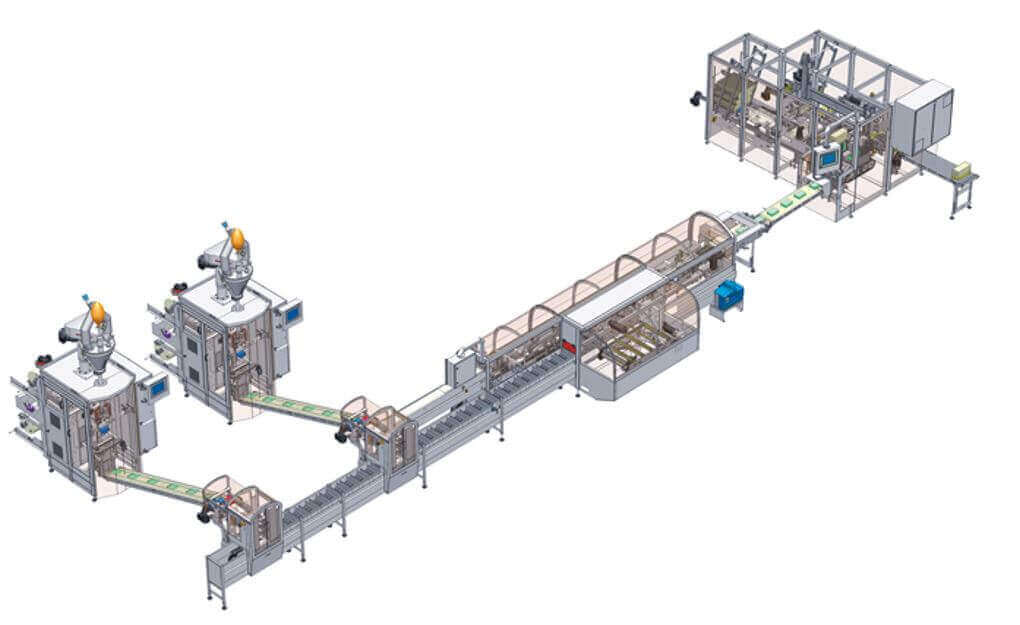

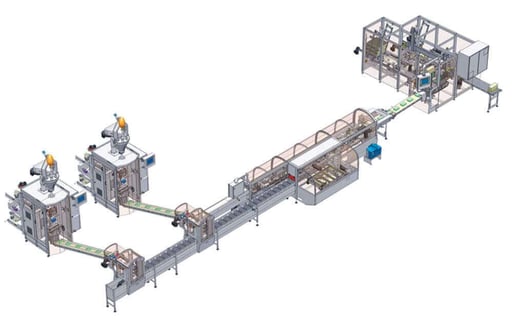

Converting production from VFFS packaging lines over to cartoning lines isn't a quick fix during times like these but with the right solution, adapting your foodservice products in pillow bags, to smaller retail sizes and even different retail-friendly bag styles could be. More pasta brands are switching to flexible packaging out of rigid cartons, and not just for the operational flexibility.

Flexible packaging machinery enables manufacturers to efficiently adapt to new market demands and in the case of the COVID-19 crisis, it helped manufacturers across many markets to have machinery that could adapt to the different priorities of retail vs foodservice.

In terms of the machinery flexibility that we just broke down, having a packaging line that can run multiple bag sizes or bag styles doesn't do your operation much good if the changeovers aren't efficient. In layman's terms, without some specific technologies, when you switch over from a pillow bag to a block bottom stand up pouch, it could take several minutes and wasted packages to get the film to track correctly or the weights to become consistent. And over time, these changeovers could become more and more challenging as your OEE declines.

Having specific features built into a flexible solution that helps to maintain consistency shift after shift, year after year, can be a significant key to success. Automatic film tracking that moves the entire film carriage to dial in the film alignment allows for the bags to run correctly only a few seconds after startup and having an automatic check weigher as well that sends feedback to the filling component to make needed adjustments can also help to make each recipe repeatable and keep your OEE in check.

Resource fluidity has often been cited as an enabler of agility within business models. But what resources in terms of packaging equipment can gain fluidity as operations are harmonized? The most popular answer? Spare parts!

Of course, this is true if many packaging and processing lines have the same machinery models, but it should be taken into consideration that often machinery from the same suppliers will need different wear parts for different models or bag sizes if the seal jaws, draw down belts or other components are different. However, being able to rely on a single source for these parts can often come with pricing and shipping efficiencies.

Another invaluable resource today is the talent and experience of your operators, maintenance teams, and engineers. When processing and packaging equipment is harmonized across different facilities, when needed, your personnel can be equipped to easily jump in to support operations at other production facilities.

Last year, and even today, skilled labor was and is a hot commodity. Many producers that had to shutter segments in the foodservice sector are still trying to recover from the decades of talent that many had to let go when these operators and engineers couldn't be retained when these lines couldn't be used to meet the surging retail demand or workers didn't feel equipped to operate equipment used at other facilities.

The manufacturing industry has seen a near-record number of job openings as the world inches back to "normal" but "77% of manufacturers say they will have ongoing difficulties in attracting and retaining workers in 2021 and beyond". It will take a long time for facilities that lost valued and skilled personnel to fully recover.

We see it even in the machinery manufacturing space- some companies operate as an amalgamation of entities which can be costly to integration, harmonization, and even communication. We often bring up the topic of single source vs single brand in our discussions with potential customers and sometimes these factors can make a difference in the harmonization of equipment.

Along with the points suggested above, the IEEE also makes a handful of excellent recommendations you can check out here that can help to ensure the success of "pandemic and post-pandemic manufacturing capabilities and operations."

Also in the context of flexibility, Rovema recently released a Bag Style Guide that takes a deep dive into how packaging equipment can help to check some of the boxes of agility, harmonization, and automation that help check the boxes for your packaging line according to what traits the IEEE pointed out as resilience enablers.

For most of us, when we decide to make a purchase, the interaction with the team that designed and produced it is short-lived. When we go to buy...

{% video_player "embed_player" overrideable=False, type='scriptV4', hide_playlist=True, viral_sharing=False, embed_button=False, autoplay=True,...

1 min read

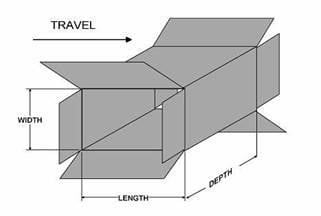

Bag in box packaging is a type of packaging method that uses a flexible package inside a paperboard carton. A bag in box package is created by...