Reimagine Your Pasta Packaging.

The Changing World of Pasta

Do you believe that the pasta industry in the US is on the brink of a dramatic market shift as much as we do?

As margins get tighter, and sustainability becomes more top of mind in boardrooms and classrooms across the world, large consumer food manufacturers are pushing to drive out more costs, be more sustainable and differentiate their products on the shelf.

Competitive and Changing Markets

Our experience is that your company has probably invested countless hours optimizing your current packaging and logistics processes in such a competitive and saturated market. You have wrung nearly every extra penny of procurement savings that you can in order to add value to your bottom line for your stakeholders and offset any expense volatility of what actually goes IN your product.

While the prices for ingredient markets have been improving, these futures are always uncertain. For a new approach to efficiency and optimization, it's time to say: "It's what's on the outside that counts!"

The status quo for the pasta industry here in the US is represented by a sea of cartons and considering just a drastic change may be daunting.

Why is challenging this "norm" an imperative?

Ready to Ditch the Box?

A Better Way: Flexible Packaging

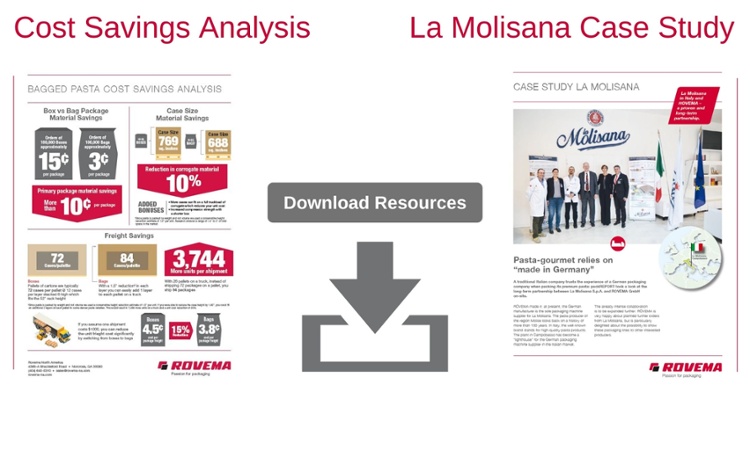

Retail aesthetics, shelf life, and convenience are recognized attributes of flexible packaging. While the benefits are clear from a branding standpoint, what if there is so much more to this switch than what your customers will experience? According to our calculations from working closely with several substrate suppliers around the country, we have come up with some astounding metrics that justify the move from cartons to film. Just on the substrate costs per unit, we estimate that this switch could result in up to 80% lower costs. Are you ready to take the leap in transforming your business?

Case Study: La Molisana and Rovema

In the Italian market, the focus for pasta today is on quality equipage and a less-is-more mentality. By using simple recipes with superior ingredients, La Molisana has gone above and beyond for over 100 years and set themselves apart in the market. In the same way that they are selective in what goes into their pasta, they are selective in the equipment to package it and there are many reasons detailed in the case study above of why they have chosen to partner with Rovema.

La Molisana has nine lines running Rovema equipment and is now exporting to their pasta to the States.

Why Rovema?

Thoughtful, broad & deep industry and consumer product insight are key characteristics needed to successfully install and operate VFFS packaging systems. With over 60 years of industry experience and numerous patents, Rovema has the expertise and partnership you need to navigate with you through this exciting transition.

Our machines are built to run for decades and as our history with many global pasta companies like La Molisana demonstrates, we support our customers not only during the initial installation but through every film and package design innovation and go above and beyond with our service and maintenance programs.

We believe that with the right partner, changing up your space in the pasta aisle is going to generate substantial savings and an ROI you can be proud of. Our machines are some of the most reliable in the market and the operating system with which they're equipped is award winning for its intuitiveness and ease of use. During the transition, we will be with you every step of the way with on-site and multimedia based training for your teams as well as world-class aftermarket support for any maintenance parts, conversion requests or service from the lifetime of your machine, guaranteed. That's the beauty of American market knowledge propelled by German engineering.

“Good employees that are easily accessible. Solid equipment.” - John B.

%20(1)-1.png)