1 min read

Lean and Mean: Our VFFS Spare Parts Pricing Overhaul

Driving out inefficiencies We know that manufacturers see spare parts as something they have to deal with to keep their machine running. Our job is...

3 min read

Emily Brogan

:

Updated on August 22, 2024

Emily Brogan

:

Updated on August 22, 2024

Editors Note: This blog was originally published in May of 2020 but has been recently re-published with additional information on this topic.

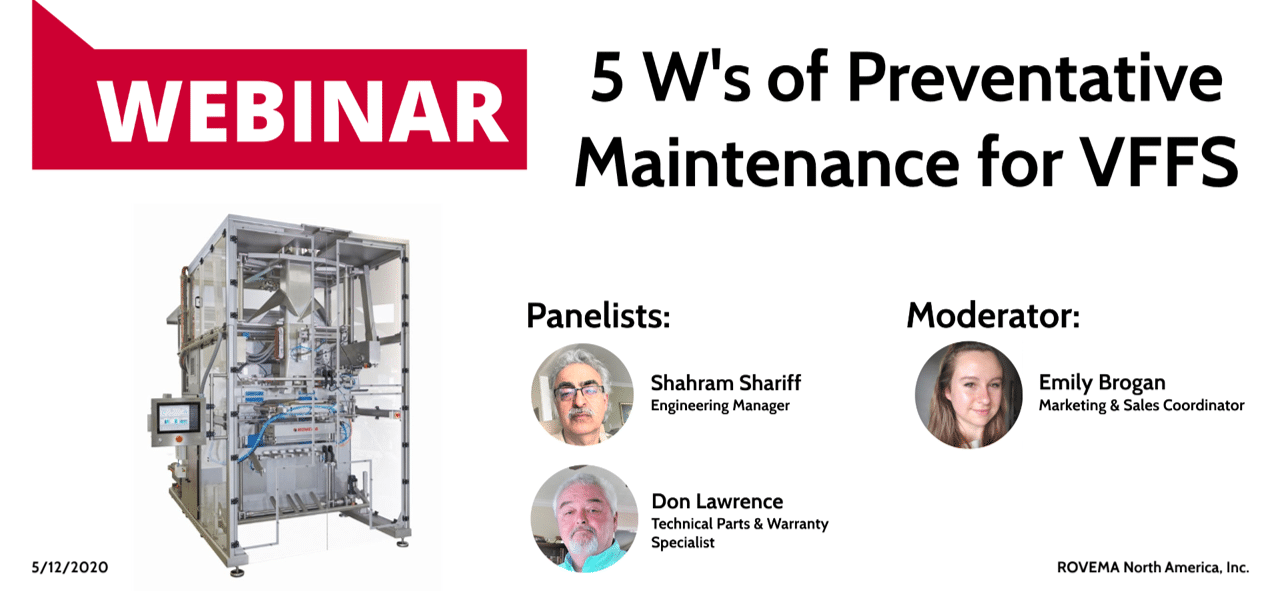

In May of 2020, we hosted a webinar on the 5 W's of preventative maintenance for VFFS Machines. Two of our experts, Don Lawrence and Shahram Shariff walked us through the four foundations of successful packaging machinery preventative maintenance: consistency, reliable spare parts, team member accountability and the maintenance schedule. They also walked us through the five benefits of upholding these foundations: maintained capacity, spare part longevity, seal integrity, downtime avoidance and lower scrap rate.

According to Don Lawrence, veteran VFFS service expert who has been with ROVEMA for 30 years, the key to upholding the 4 foundations and achieving all 5 of the outcomes that were covered in the webinar came down to the first 10 minutes of the VFFS operators shift. If you happened to miss it, no worries, the full recording is posted here.

We had a great turnout for the webinar and received positive feedback from many of our customers. It was a great feeling to know that it was beneficial to so many, not just in the USA but across the globe.

At the end of the webinar, we held a question and answer session, and received way more questions than we had time to answer so we are sharing them here along with our answers in hopes that it can help even more people with all their VFFS service needs.

If you took the time to watch the webinar recording and you had your own questions come to mind, shoot them to us! We bet you’re not the first to think of it and we would like to add it to this post. You can reach out to us on our contact page or in the live chat. 👉👉👉

At the end of the day, consistently performing the recommended daily, weekly and monthly tasks are the name of the game when it comes to downtime prevention and maximizing your OEE over the life of your machine.

But there are other key insight areas you should be considering. Take a deeper dive on VFFS maintenance by checking out PMMI's ProSource article that provides 7 key areas you need to be taking into account for the maintenance of your form/fill/seal equipment.

Stay tuned for announcements on our next webinar topic!

1 min read

Driving out inefficiencies We know that manufacturers see spare parts as something they have to deal with to keep their machine running. Our job is...

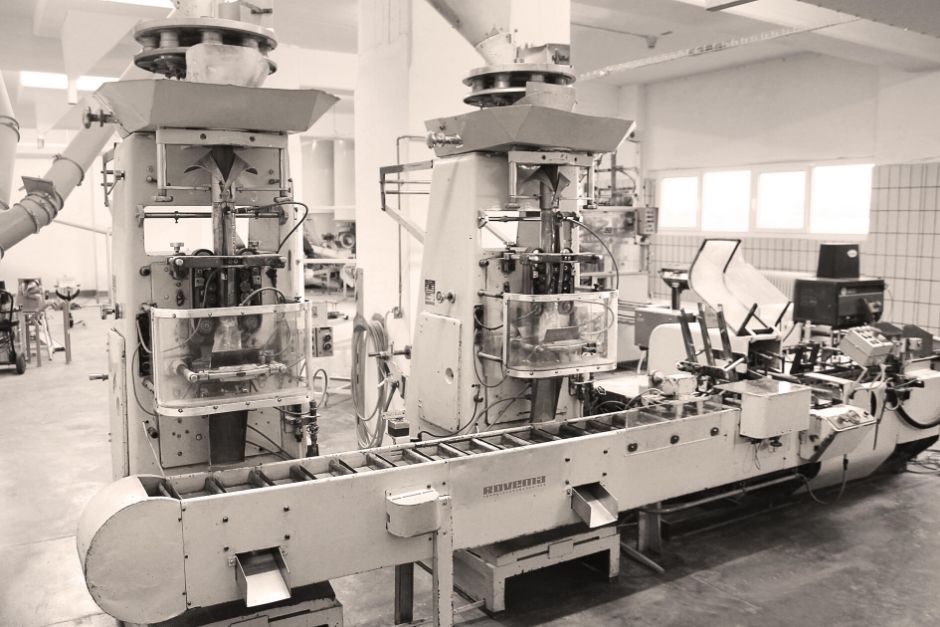

So You Have a Reliable...but Aging Vertical Form Fill and Seal Machine. Does your production team have nicknames for vertical form/fill/seal machines...

For most of us, when we decide to make a purchase, the interaction with the team that designed and produced it is short-lived. When we go to buy...