Troubleshooting 5 Common Electrical Problems With Your VFFS

Packaging machinery is an important feature in managing and branding your product. Your vertical bagger should improve your OEE (Overall Equipment...

5 min read

Info : Updated on September 17, 2025

Editor's Note: This resource was first published in March of 2017 but is frequently updated with new relevant information.

When your packaging line goes down at 2 AM, you need answers fast. Here's your field guide to the most common VFFS film issues and how to resolve them.

Information for almost any subject is available instantly. Pull out your phone, type a question, and get immediate answers. But if you're managing a packaging operation and your VFFS machine starts acting up, you'll quickly discover this is one area where helpful online resources are surprisingly scarce.

Picture this: You're overseeing third shift operations when film tracking goes wrong on your vertical form-fill-seal line. You search "Why is my film not tracking on VFFS?" and find nothing but ads and generic brochures. Meanwhile, your line stays down and costs pile up.

No operation can afford extended unplanned downtime. Every minute of disruption wastes resources, delays shipments, and impacts your bottom line. Quick problem identification prevents minor issues from becoming major production disasters.

Drawing from decades of field experience with Rovema machines, Allen Overmyer has identified the 11 most frequent film-related issues that disrupt Vertical Form Fill Seal machine operations. These problems account for the majority of unscheduled maintenance calls and emergency troubleshooting requests.

Problem: Film consistently drifts to one side during operation, causing alignment issues and potential seal problems.

Root Causes to Check:

Quick Fix: Start with spindle centering—this resolves 80% of off-center film issues. If the problem persists after centering, inspect the film roll quality and belt alignment.

Problem: Film wanders or shifts position unpredictably during operation, making consistent bag formation impossible.

Root Causes to Check:

Quick Fix: Re-thread the film following your machine's threading diagram. Loose spindle mounting is often overlooked but frequently causes tracking issues.

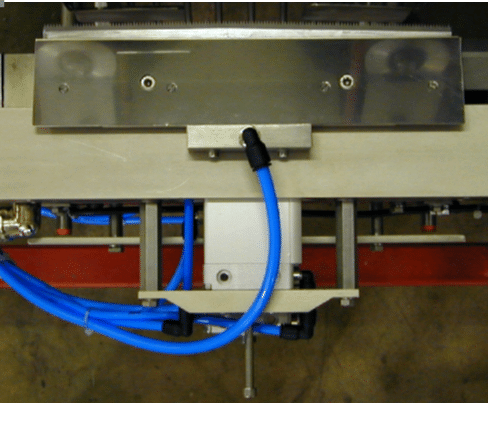

Problem: Feed belts fail to advance film, stopping production completely.

Root Causes to Check:

Quick Fix: Check belt tension first- overtightening is the most common cause. If belts move freely by hand but won't engage, inspect the drive system.

Problem: Finished bags vary in length, creating issues with case packing and product presentation.

Root Causes to Check:

Quick Fix: Clean the feed belts first—buildup from film additives or environmental contamination frequently causes slippage that leads to length variation.

Problem: All bags exceed the target length consistently.

Root Causes to Check:

Quick Fix: Verify the bag length setting in your control system matches your product requirements. Registration eye misalignment can add unexpected length to each bag.

Problem: Wrinkles or creases appear in the film, affecting bag appearance and potentially compromising seal integrity.

Root Causes to Check:

Quick Fix: Inspect the forming collar first, wear patterns are usually visible. Clean all contact surfaces before making adjustments.

Problem: Film resists unwinding from the roll, requiring excessive force and potentially causing web breaks.

Root Causes to Check:

Quick Fix: Clean the forming tube and collar assembly. Many unwind issues stem from film additive buildup that increases friction.

Problem: Excessive resistance when film moves through the forming section, potentially causing web breaks or stoppages.

Root Causes to Check:

Quick Fix: Start with a thorough cleaning of the forming set. Check for splice tape remnants—they're easy to miss but cause significant drag.

Problem: Film bunches up or jams at the forming tube entrance, stopping production.

Root Causes to Check:

Quick Fix: Reduce vertical seal temperature and pressure. Film sticking to hot sealing surfaces is the primary cause of forming tube jams.

Problem: Belts can't maintain grip on the film, causing irregular feed and bag length variation.

Root Causes to Check:

Quick Fix: Clean the belts and check vacuum operation. Many slipping issues are resolved by removing film additive buildup and ensuring proper vacuum assist.

Problem: Film adheres to the vertical sealing band, causing web breaks or poor seal quality.

Root Causes to Check:

Quick Fix: Reduce temperature and pressure settings. Clean sealing surfaces to remove any film buildup that increases sticking tendency.

Film structure changes can dramatically affect machine performance, even when the supplier reports "equivalent characteristics." A film that ran perfectly last month might cause multiple issues after a supplier reformulation or manufacturing change.

Communication between procurement, operations, and machine operators prevents confusion when performance suddenly changes after a roll change. Document any film specification changes and adjust machine settings accordingly.

Most of the issues covered here require minor adjustments, cleaning, or small parts replacement. But if you're fighting these problems consistently, there might be a larger equipment issue.

Frequent troubleshooting indicates:

Modern VFFS machines include features like automatic tension control, servo-driven adjustments, and predictive maintenance alerts that prevent many of these common problems.

While preventive maintenance and quick troubleshooting keep your current equipment running, persistent issues signal it might be time for a conversation about upgrading your packaging capabilities.

If you're spending more time troubleshooting than producing, or if these issues are impacting your ability to meet customer commitments, we'd be glad to discuss how modern packaging technology could improve your operations.

Ready to move beyond constant troubleshooting? Contact our team to explore packaging solutions built for reliability, not just speed.

Packaging machinery is an important feature in managing and branding your product. Your vertical bagger should improve your OEE (Overall Equipment...

Recently, I had the opportunity to sit with Allen Overmyer, senior technical advisor and one of Rovema's "big guns" for an interview to discuss the...

Maintaining an efficient and well-run production environment is an important key to success. It saves on unplanned downtime, cost and stress. You can...