How Single-Source Packaging Lines Eliminate Multi-Vendor Problems

Why Multi-Vendor Packaging Line Integration Creates Costly Support Bottlenecks Picture this scenario: It's week three of your new packaging line...

3 min read

John Panaseny

:

Updated on August 8, 2025

John Panaseny

:

Updated on August 8, 2025

Complex engineered packaging machines and lines have the potential to greatly enhance production efficiency. However, it is important to note that these complex systems can also pose challenges if not properly planned and managed. For a project to be successful, it requires meticulous planning, well-defined acceptance criteria, thorough commissioning and training, and robust maintenance procedures.

As multiple pieces of equipment are integrated into production lines, the level of complexity increases significantly. This complexity encompasses a wide range of factors, from straightforward aspects such as signaling and controls, to more nuanced considerations like successive surge capacity requirements and the integration of various disciplines including electrical, mechanical, safety, and process engineering. It is crucial to carefully navigate this complexity in order to maximize the chances of long-term success.

As complexity has increased due to higher speed, increased automation, and the expectation of lean and efficient operations, more CPG packaging projects have fallen short of meeting the expectations on which justifications and production planning were based.

In response, the packaging machinery industry has emphasized the importance of single source solutions. However, this term means vastly different things to different people. It generates confusion.

When you think of single source packaging lines, which of the following do you envision?

All are viable models. The substantial variations, though, highlight the need to dig a bit deeper in evaluating packaging solution providers.

In the packaging industry, the term "single source" typically refers to either a common brand of machinery or the integration of various equipment by a third party. It is crucial to understand the context of this term, as it carries different connotations for buyers and sellers.

One example of its usage is by global conglomerates, which have seen significant consolidation in the packaging machinery business over the past decade.

These conglomerates have acquired niche machine/technology companies to enhance their offerings in growth industries like pharmaceutical and food packaging.

That means that in many cases a single sales rep may sell automated packaging systems as single source (the logo on the rep's business card matches the logo on each machine) that are actually designed, engineered, manufactured, tested and shipped from entirely different companies.

These companies may have different management, engineering, and support teams, and they may be located in different factories and even different countries, with communication in various languages such as German, Italian, Japanese, and English. Furthermore, these machines may also adhere to different design standards, such as metric vs. SAE and CE vs. UL.

And then....this single source line arrives at a customer facility in different crates, through different customs brokers, with a hope that integration isn't too problematic. That's one definition of single source.

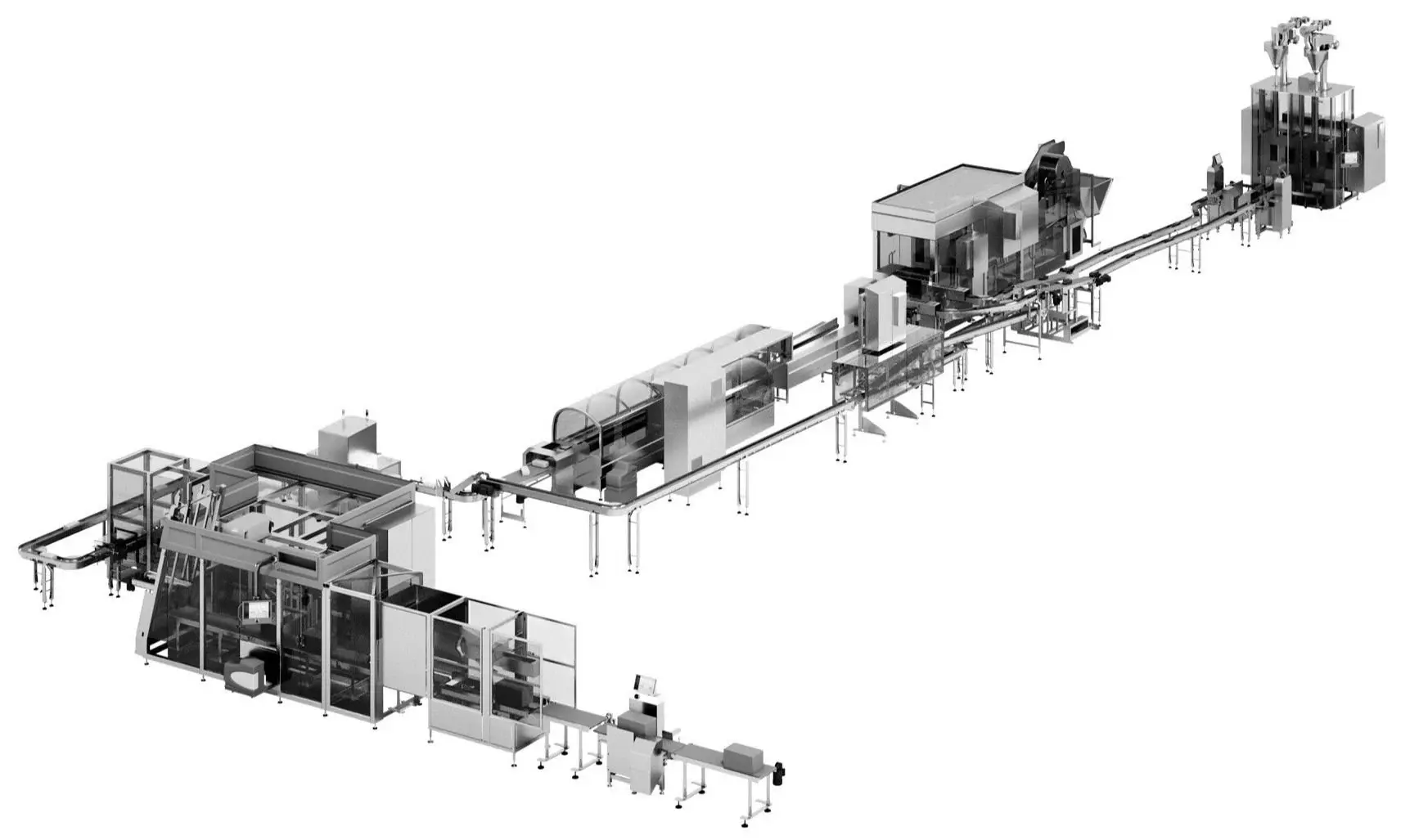

There's another simpler definition - one team for all machines: design, engineering, manufacturing, acceptance testing, commissioning, training and support by people who share the same cafeteria. In this case not only is signaling clear to a single EE team, but a common HMI simplifies operation. An entire line assembled, debugged and accepted in the manufacturing facility can dramatically improve project outcomes. That's real single source. And in this model the ongoing customer support is often provided locally by native language speakers with deep application and technical knowledge and local parts inventories.

But does this matter? Should CPG companies really worry about this distinction? The answer is 'Yes.'

Anyone that's ever lived through the misery of gradual integration can immediately empathize. Missed production delivery dates, cost overruns, persistent skepticism by operators and maintenance and unmet justifications are sadly common. Nearly every facility has experienced at least one of these despite careful engineering planning.

The risks are growing though. As plant engineering and maintenance teams are cut further and further, the few remaining staff and production teams can't support field integration. Lines must arrive tested, debugged and ready to run. True single source - built and integrated under the same single roof - is the only viable solution. (This is one of Rovema's core commitments. It's the reason for significant recent investment in expanding our factory - with more planned.)

The pressure on staffing and resources is increasingly straining maintenance operations. Statistics from the Plant Engineering 2016 Plant Maintenance Survey are noteworthy. Highlights include:

Ultimately, it is evident that there is a clear distinction to be made. A simple misunderstanding in terminology, such as the difference between a single source from the same factory and team versus a single source with the same global brand, can have a significant impact on the outcome of a project. Therefore, it is essential to exercise caution and diligence during the procurement process to ensure that a robust support system is in place. This includes having access to replacement parts, telephone support, programming capabilities, and field service are available within a couple time zones and next day delivery. Ongoing operations require this level of attentiveness to guarantee a smooth and efficient workflow.

The trend in maintenance staffing is unlikely to reverse, and quite likely to continue. When you compare machines, including replacement vertical baggers, make sure you consider others' experience with support as part of your decision criteria.

And not only can lines be more efficiently integrated, but existing lines can also be more efficiently operated. Check out or step-by-step playbook for boosting VFFS operational equipment effectiveness in your facility.

Why Multi-Vendor Packaging Line Integration Creates Costly Support Bottlenecks Picture this scenario: It's week three of your new packaging line...

Spending some to save more Industrial operations, especially in the food industry, are all about minimizing costs, both operational and capital....

Technology continues to amaze me. I’m sure I am blind to a majority of what is out there outside the packaging world, but from what I am aware of,...