3 Reasons Degassing Valves Are Important to Coffee Packaging

You’ve heard the question, "If you were on an island and could only take three things, what would you bring?" It may take me a minute to come up with...

3 min read

John Panaseny

:

Updated on August 8, 2025

John Panaseny

:

Updated on August 8, 2025

While oxygen is essential for our survival, it can be detrimental to the freshness and quality of coffee. Roasters worldwide face the challenge of meeting the increasing demand for high-quality coffee while ensuring that the roast remains fresh and flavorful for an extended period. Oxygen, the archenemy of fresh coffee, has the potential to rapidly deteriorate the flavor and aroma of a roast or grind, dampening the enjoyment of your customer's morning brew.

Fresh coffee is great coffee and the proper coffee packaging is so important for freshness!

The most popular method is Modified Atmospheric Packaging (M.A.P.) or Nitrogen gas flushing. Nitrogen gas flushing is simply a method of introducing inert nitrogen gas into the bag during the packaging process. As the odorless, inert Nitrogen is flushed into the package, oxygen is displaced allowing the coffee to keep its freshness with a longer shelf life to preserve its quality.

If you do your research, you will find that numerous taste tests have been conducted to prove a Nitrogen flushed bag of coffee brewed several days or weeks after packaging retained its delicious just roasted taste, freshness, and quality compared to a bag that was not flushed. The proof is there, Nitrogen gas flushing is essential to coffee packaging.

Now that you know how important gas flushing is, let’s talk numbers. What is the ideal residual oxygen level to ensure quality, freshness, and increased shelf life to keep your customers happy and returning for more?

Research has demonstrated that oxygen levels above 5% can lead to significant oxidation, negatively impacting the freshness and quality of coffee within days of packaging. As a result, it is recommended to maintain a residual oxygen level of no more than 3%. However, many roasters who prioritize high quality and customer satisfaction often strive for even lower levels to safeguard the flavor and freshness of their coffee for an extended period, particularly ground coffee which is more susceptible to oxygen degradation. Achieving levels lower than the minimum recommendation can provide opportunities for contract and private label roasters.

In many cases, when participating in a bidding process for contracts, particularly with larger companies, it is often required to maintain a residual oxygen level of 2% or lower. Being able to achieve this level could be the determining factor in securing a highly profitable contract.

You might be asking yourself, “How do I achieve these low residual oxygen levels with my vertical, form, fill and seal machine?” When a coffee customer requires a residual oxygen level of 2% or less, Rovema recommends a special closed system, this being our Aroma Perm Gas Flushing System. The special Aroma Perm® Gas Flushing System was originally developed to meet the stringent oxygen levels for the infant milk powder industry.

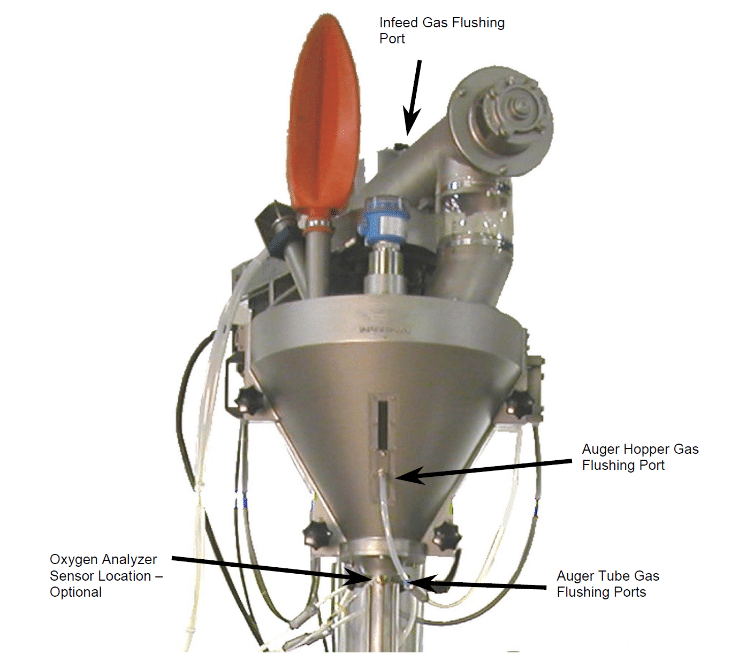

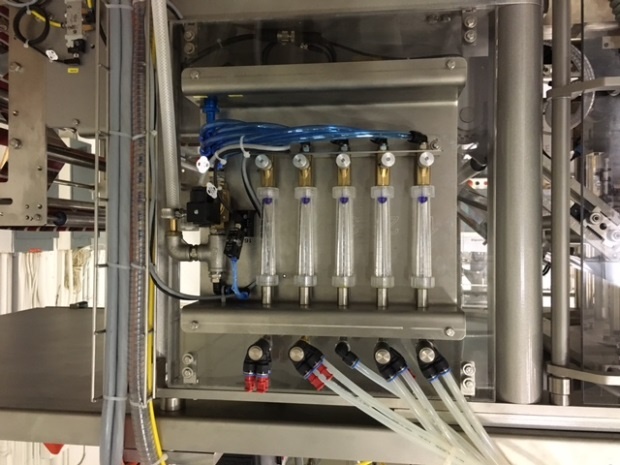

With its success, our coffee customers can also reap the benefits of this system to obtain unsurpassed residual oxygen levels. Integrated into our vertical bagger, the proven Rovema Aroma Perm® Gas Flushing System is a closed system that features inlets ports and control valves to flush nitrogen into the auger hopper, forming tube, and optional horizontal cross feeder. The system also has a control valve to flush nitrogen into a customer’s supplied storage bin above the auger if applicable. The system features a compensation balloon that creates a closed system to prevent air from entering or leaving the hopper.

Rovema has several coffee customers achieving residual oxygen levels around the .08% level with the Aroma Perm® system to meet the most stringent requirements.

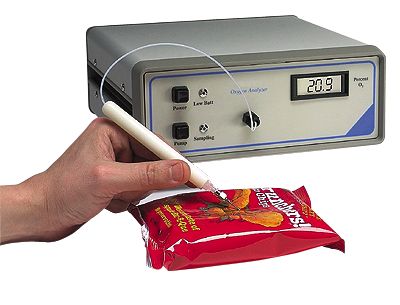

Once you have achieved the “perfect” bag with gas flushing, it is important to routinely monitor and test oxygen levels in the package for quality control/assurance. There are a couple of devices that can be used to ensure the appropriate levels of oxygen are being achieved. The most common device is a bench top head space analyzer used to measure oxygen levels in a sealed bag that is randomly taken off the packaging line and tested by Quality Control.

The alternative to the bench top head space analyzer is an on-line analyzer that continuously monitors oxygen levels during packaging and it is part of the packaging machine system. The on-line analyzer makes sure the MAP system is always working properly to keep your coffee fresh. The on-line analyzer can also automatically regulate the gas flow and ensure oxygen levels stay at a predetermined amount.

Here is a Rovema Continuous Motion BVK-260 VFFS and SD-81 Auger in action:

You’ve heard the question, "If you were on an island and could only take three things, what would you bring?" It may take me a minute to come up with...

There are numerous reasons why someone may consider a vertical packaging machine for their coffee packaging needs. Your business may be expanding and...

1 min read

Welcome Back: The Rovema Brown Bag Blog Series Hello hello! We hope you’re doing well. Welcome to this month’s edition of our Brown Bag Blog...