The Maximizing OEE for Vertical F/F/S Guide

Every consumer packaged goods (CPG) company in North America faces common challenges. Retailer and consumer expectations for package appearance,...

2 min read

John Panaseny

:

Updated on August 8, 2025

John Panaseny

:

Updated on August 8, 2025

Editors Note: This blog was originally published in July of 2016 but has been edited and republished with new data around this topic.

OEE might be best known among large multinational companies, but it isn’t out of reach for companies of any size. Often the source of slowdowns and bottlenecks between products and sales, vertical baggers are one of the best places to start implementing OEE - Also known as Overall Equipment Effectiveness.

Your OEE target has two elements. First is the target output - generally measured in completed cases/unit of time. The second element is the actual performance against that target. As a rule of thumb any individual machine should achieve at least 98% efficiency. It’s important to understand that calculation, though; both for individual machines and an entire line.

This is a total output measurement and all disruptions are included. So if your target is 500 cases/shift and you lose time looking for more seal strip in the warehouse or ink for the printer, that time counts against you. Film changeovers do as well.

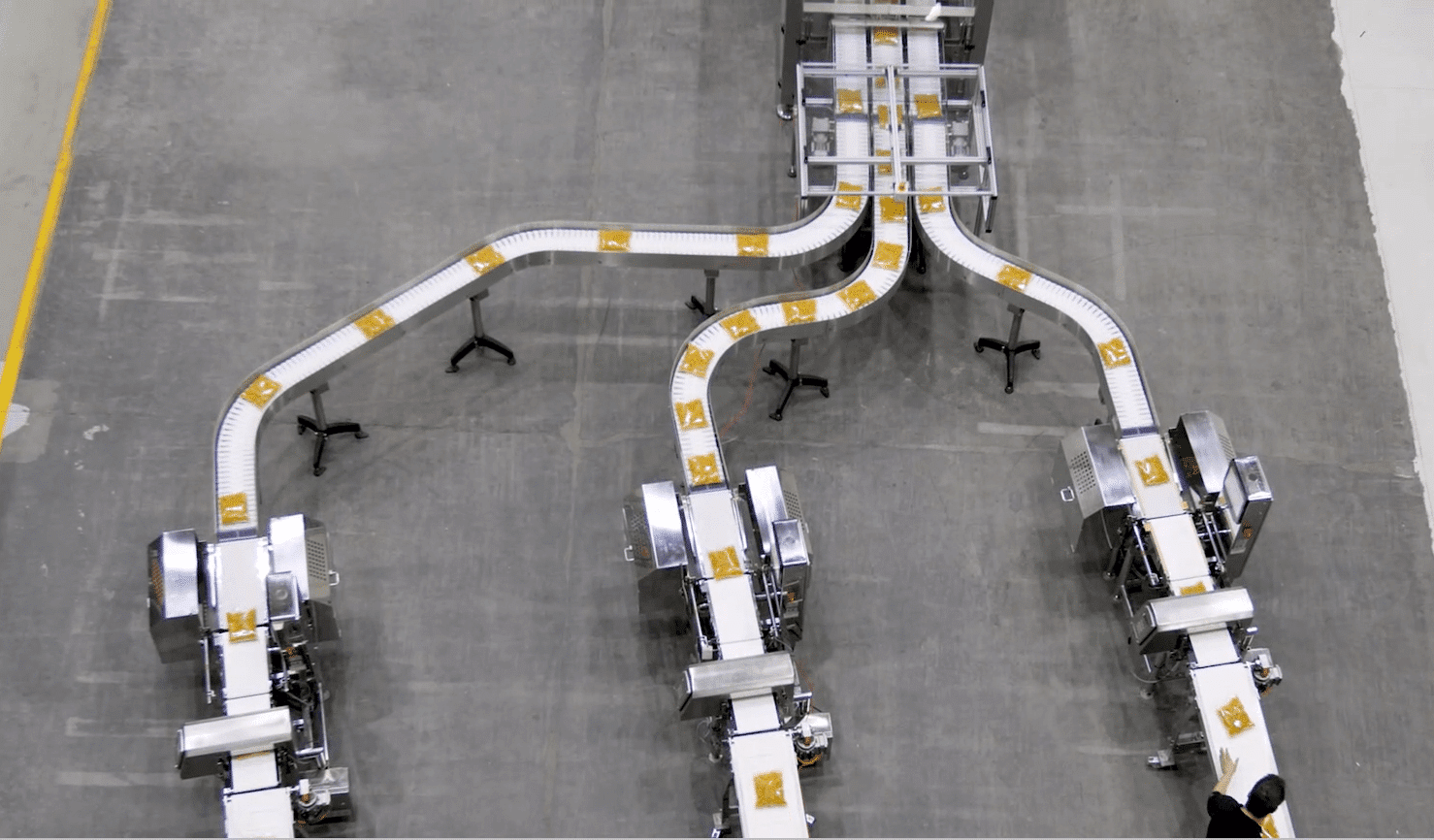

Most production lines run at around 85% in well-managed operations. Why 85% when any individual machine should maintain at least 98%? The cumulative effect of inefficiency. A typical line consists of:

If each of those operates at 98% efficiency, the best cumulative efficiency which could be achieved is 92% (.98 * .98 * .98 * .98 = 92.2) Accounting for hand pack-off, a typical operation may reasonably target 90%.

Multinational corporations may seem to have some advantages over their small and medium business counterparts. With centralized engineering resources and well-developed methodologies to monitor and optimize OEE, multinational corporations seem to have an edge that small and medium operations do not.

However, the truth is that the same best practices that work for large companies can be just as effective for small and medium businesses. With a commitment to actively and consistently working toward OEE optimization, there is no reason any operation, no matter the size, can achieve impressive operational improvements through improved equipment availability, performance, and quality.

When you begin OEE optimization your first step needs to be defining the specifications your machine needs to hit. This means knowing ahead of time things like customer expectations, what’s a film issue vs. machine set-up, target profitability run rate, etc. If your metrics only include cycles/minute then it’s time to go back to step one.

In general, the specifications you need will include product, material, and packaging metrics. Every application will be different and may require other specific details, but, in general, the following details are good places to start.

These specifications should be documented, agreed to, and posted near the equipment for reference.

Once you’ve established your specifications, what’s next?

To help you find your next step, we’ve created a starting point and step-by-step playbook so that every operation can implement the same sort of rigorous OEE improvement process that the multinationals rely on for their competitive edge, The Maximizing OEE for Vertical Bagging Operations Guide!

Click here or follow the link below to get your free copy of the Maximizing OEE for Vertical Bagging Operations Guide.

Every consumer packaged goods (CPG) company in North America faces common challenges. Retailer and consumer expectations for package appearance,...

4 min read

“The leading cause of unscheduled downtime within respondents’ facilities remains aging equipment (42%).” For those of you concerned with...

Editors Note: This blog was originally published in March of 2021 but has been edited and republished with additional content around this topic. ...