Lowering Operating Costs with VFFS Maintenance and Repeatability

A wise man once said, “An ounce of prevention is worth a pound of cure.” That wise man was none other than the founding father, Benjamin Franklin. In...

6 min read

Emily Brogan

:

Updated on June 5, 2024

Emily Brogan

:

Updated on June 5, 2024

Efficient machine maintenance is crucial to the smooth operation of any manufacturing or packaging operation. Downtime costs money … a lot of it. And if a company is implementing lean manufacturing processes, maintaining the equipment properly is an important part of the equation.

If you're a maintenance manager, this concept is something you're all too familiar with

We recently had a chance to talk to Steve Maurer, an industrial maintenance electrician for a major food and beverage company. We asked him what he'd recommend new maintenance team members should know when starting out.

What he told us, after 36 years in the industry, focused more on mindset and the 'soft skills' necessary to succeed as a maintenance technician.

If you're involved in the hiring process (and you should be), then this article will give you some ideas to look for in job applicants. It presents a roadmap to follow, helping the new maintenance team member develop in the first few months of employment.

"I've been a maintenance technician for well over 30 years. While most of what I do these days is on the electrical side of troubleshooting and repair, I started life as a lubrication tech. And honestly, that gave me a heads up on what it takes to be a top-notch machine tech.

I learned the machinery's operation from top to bottom.

Over my 36 years of wrench-turning experience, I've seen a lot of team members come and go. Some of them retired, of course. But many left the craft because they just didn't develop the attitude it takes to be a skilled technician."

"While there are a lot of skills needed to perform and finish quality work, I've broken it down into four main areas and their subset of skills.

The four are:

Each of the areas should be in every maintenance tech's skillset, or as I call it, getting the MEMO."

"As I mentioned, I've worked in the food and beverage industry for over three decades. I'm looking forward to retirement, though. But in those years of experience, I've noticed something that really separates the rock star maintenance team member from the, well, rank amateur. It can be summed up in one word.

Mindset.

Granted, not every new maintenance applicant or team member exhibits the right mindset for the job right off the starting blocks. If they're "green" and inexperienced, they might not understand what the proper attitude is coming into the job. But it's something that can be developed.

And you, the maintenance manager, can help instill the right mindset, at least for those willing to develop it.

So, what mindset am I talking about?

The attitude or mindset that what they do is significant, crucial to the company's success. The knowledge their work performance affects the company's profitability, and thus, the livelihood of all employees in the operation.

It may sound like a somewhat lofty notion. But it's true, nonetheless."

"Maintenance costs are often treated as just a line item on an expense report. But, when truly understood, a good maintenance operation affects the company's profitability in a positive way.

After all, if the machines don't run, no product is produced. And if no product is produced …

You get the picture, right?

A new maintenance team member also needs to develop a sense of pride in their work. Early in my career, I viewed myself as more than "just" an employee. The work I did reflected back on me.

Not only did I do a better job as a maintenance tech, helping the company make more money, but it affected my personal bottom line. I moved up the maintenance ladder from 'wrench turner' to plant electrician."

"I like the fact that trade schools seem to be more prevalent these days, garnering more attention in the news and social media. Not everyone needs or even wants an office job. Some people would rather "turn a wrench" and perform packaging equipment maintenance than crunch numbers on a computer in an office.

Machine maintenance is just as important as office work.

If you can snag a trade school graduate, do it. They've been trained in the basic skills needed for maintenance operations. Some may even have specialized training in refrigeration or other disciplines.

But make sure they understand that school isn't out yet. In fact, if they want to develop, grow, and advance … it never is."

"A regimen of both formal and in-house training will always be part of the mix.

As a maintenance manager, there's a lot you can do in the onsite educational process. If you see a new maintenance team member that shows potential, partner them with an experienced hand.

I worked with one new hire that took extensive notes whenever I showed him techniques and tricks to make the job easier. In a short time, he had a pile of notebooks to refer back to when necessary.

Some of what I showed him wasn’t found in any machine manual. It was information gleaned from hard-learned experience. And because he wrote it down, that knowledge will be passed on down, long after I'm gone.

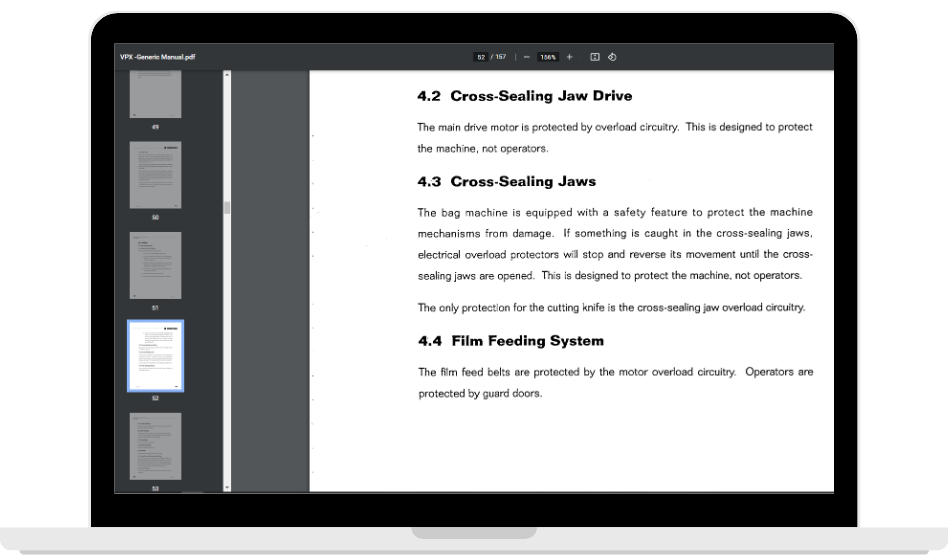

That reminds me, make sure they read the machine manuals! Believe it or not, there's a lot of valuable stuff tucked away in there, written by the people who developed and built the system.

I can't count the number of times that struggling technicians came to me with a problem they couldn’t figure out. All I needed to do was open the manual and show them the answer.

One of my most important bits of advice to any new maintenance team member is, "Read the book!"

Another thing I highly recommend is for the team member to study the equipment in operation. When we got a new vertical packaging machine a number of years back, that's exactly what I did.

I grabbed a stool, plunked my butt down in front of it, and watched it work its magic for hours at a time. Before long, I could see malfunction "clues," even in my periphery vision. Getting familiar with the machine's operation is a vital part of a maintenance tech's education. Urge your new team members to do that instead of sitting around, drinking coffee.

I also search the Internet for tips and tricks, often on the machine manufacturer's site."

Rovema-na side note: A lot of machine manufacturers like us post instructional videos and webinars on their website. The videos often cover basic cleaning and lubrication tasks, as well as more advanced and complex procedures. The information presented there is invaluable.

"Everything we've discussed so far triggers the development of a maintenance methodology. From getting the right attitude to reading the manual and understanding the machine's operation, each step becomes part of an ongoing methodology for maintenance task performance.

In other words, they build good work habits."

Good work habits, including using the right tools for the job (a pet peeve of mine), create a more efficient and effective maintenance process.

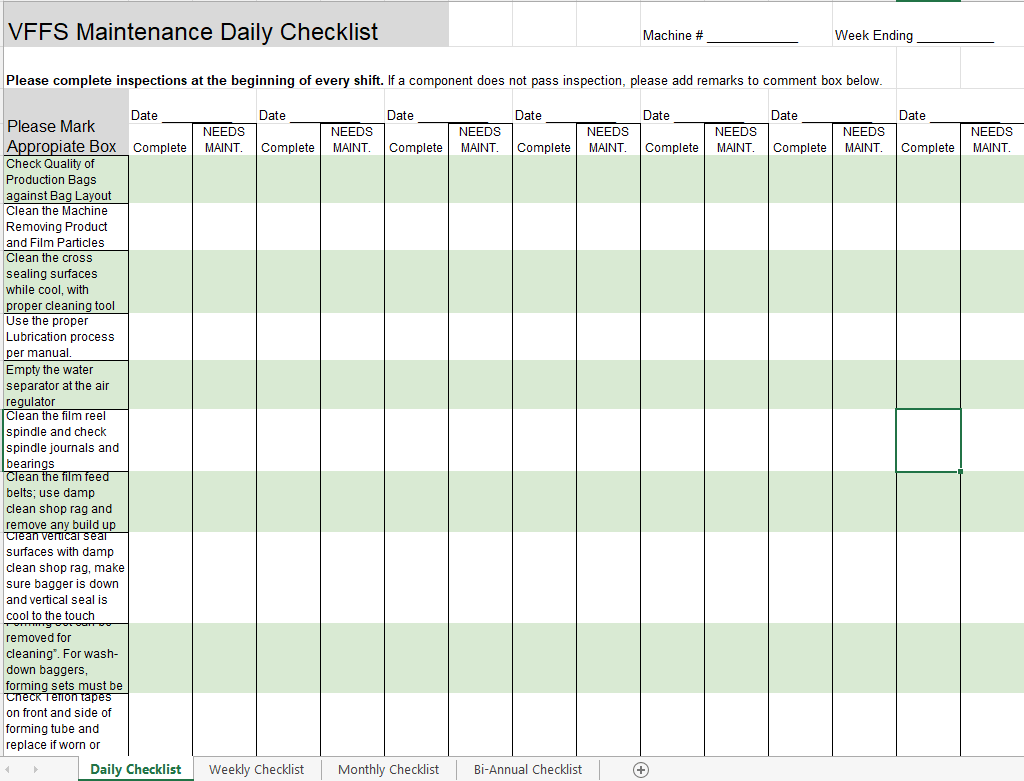

One of the steps involved in an effective maintenance habits is developing preventive maintenance schedules for your machines and sticking to them. This includes:

By doing these on a routine basis, your team develops troubleshooting and maintenance habits that almost run on autopilot. If you see techs stop and listen because something doesn't sound right, you know they're learning and absorbing the training.

There could be other recommended preventive maintenance tasks, usually found in the machine's operation manual. Once again, we see the importance of "reading the book" for useful information."

If you need help in creating a good preventive maintenance plan for your machines, check the manufacturer's website. Often they'll have downloadable checklists available for specific machines, as well as general good maintenance suggestion.

Keeping a detailed, written log sheet or checklist accomplishes other important functions:

ROVEMA: Tell us more about this "ownership" idea. It sounds intriguing. What is it?

"Honestly, when I see this happen, my heart swells a bit with pride. Not only does the team member understand the gravity of their importance as a maintenance technician, but another change happens.

The new maintenance team member really "graduates" from school, whether formal or on the job. What they do becomes more than "just a job." Processing and packaging equipment maintenance morphs from what they do into who they are.

They don't just fix machines. They've become machine maintenance specialists. And in doing that, they take ownership of not just their skills, but of the entire facility's upkeep.

For a maintenance manager, that's the highest level of commitment to instill for your team members. The plant runs more smoothly, and everybody is happier."

ROVEMA: Do you have any final thoughts?

"Building a top notch maintenance crew takes time. But having a plan for your team member's development pays off in the long run.

So, send them the MEMO. You'll develop a better machine maintenance team if you're involved in their:

Show a genuine interest in their growth as technicians and you'll reap the rewards faster."

%20(1).png?width=435&name=Preventative%20Maintenance%20Schedule%20Downloadable%20Template%20(1)%20(1).png)

In the Methodology section, Steve talked about using preventive maintenance schedule or calendar. If you don't have one developed, we can help. Download our customizable Preventive Maintenance Schedule Template here and speed up the process of developing your preventive maintenance plan.

A wise man once said, “An ounce of prevention is worth a pound of cure.” That wise man was none other than the founding father, Benjamin Franklin. In...

We know from experience that keeping production buzzing is so much more than staying on schedule. It’s cliché to say there are a lot of moving parts...

4 min read

“The leading cause of unscheduled downtime within respondents’ facilities remains aging equipment (42%).” For those of you concerned with...