VPI Weekly Inspection

What maintenance should you be performing on your bagger on a weekly basis?

Weekly inspection of your machine will help prevent mechanical malfunctions. When inspecting your machine, you should look for component wear and check for proper component operation. This section indicates which components should be inspected and what to look for during the inspection.

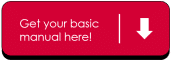

Knife Actuation

Check that the cutting knife extends and retracts smoothly. You can screw a 6mm bolt into the end of the extend/retract air cylinder to manually actuate it.

Examine some of the bags from the last production run to see if the knife is cutting cleanly through the packaging material. If it is not, replace it (refer to section 6.0, Working with Components, Replacing the Cutting and Perforation Knives).

Danger: Be sure that you hands are clear of the cutting area when extending the cutting knife, and, wear protective gloves.

Figure 7.5

Shows how to use a 6mm bolt to extend and retract the knife.

Weekly Inspection

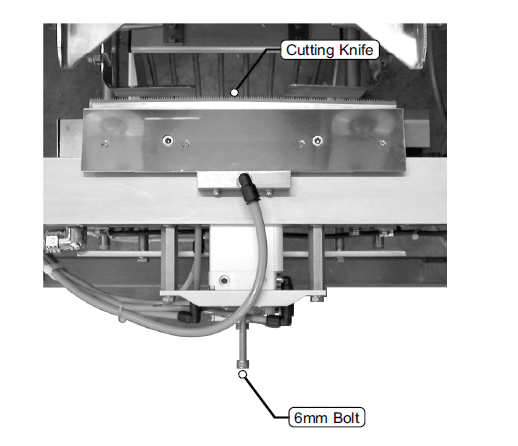

Film Transport Belts Check the surfaces of the film transport belts for excessive wear. Replace them if necessary (refer to section 6.0, Working with Components, Replacing the Film Transport Belts).

Weekly Inspection

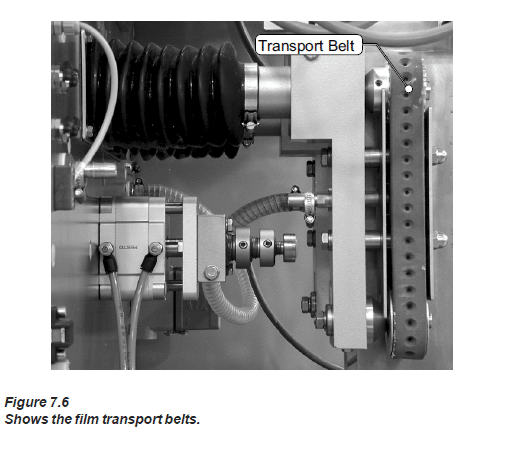

Forming Tube Tape

Check the condition of the Teflon® tape on the forming tube. If there are holes or tears in the tape, replace it.

Weekly Inspection

Guide Rollers Check that the guide rollers from the dancer assembly up to the setup roller assembly spin freely. If a roller spins sluggishly, repair or replace it.

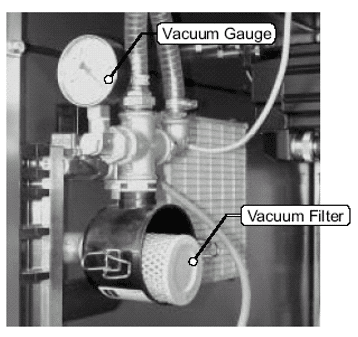

Vacuum System Check the condition of the vacuum system by reading the vacuum gauge. This should be done during normal bag product, while the vacuum system is active. If the vacuum gauge reads below 10 Hg., replace the filter.

------------------------------------------------------------------------

More Rovema Support Options

See Additional Mechanical Articles

Looking for a manual for your Vertical Form Fill and Seal (VFFS) Bagger? Click here!