Daily Cleaning - VPI

What maintenance should you be performing on your VPI bagger on a daily basis?

Daily cleaning is one of the most important measures that you can take to maintain the bagmaker. Product debris builds up very quickly and should be removed from the machine once each day. This section describes the parts of the bagmaker that should be cleaned.

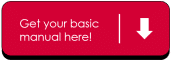

Food Contact Surfaces Proper sanitation of food contact surfaces is of the utmost importance. It will help prevent contamination of your bagged product. There are three bagmaker surfaces that contact the product; the product funnel, the filling tube, and the bag spreaders. These parts must be removed from the machine and sanitized in accordance with all Federal, State, and Local regulations.

Warning: The food contact surfaces must not be reinstalled until they are clear of product debris and the disinfectant used to sanitize them.

If you need assistance in determining how to sanitize the food contact surfaces for your particular application, please contact the Rovema Service Department.

Figure 7.1

Shows the food contact surfaces. The bag spreaders are not shown but would be located at the bottom

of a round forming tube.

Daily Cleaning

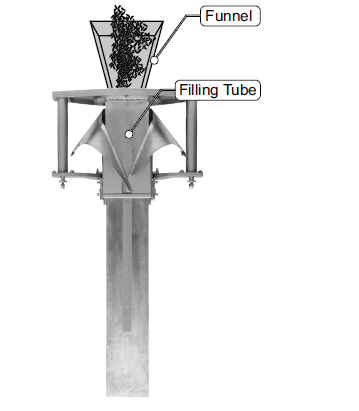

Machine Housing Cleaning the machine housing will help prevent sanitation problems. Remove product debris by vacuuming or sweeping it from the horizontal surfaces of the machine.

When cleaning painted surfaces, commercially available cleaning and polishing agents can be used. Also, commercial available mild household cleaners may be applied using a moist cloth.

When cleaning plastic protective coverings, we recommend that you use an antistatic cleanser (e.g. Hascherix 212-Rovema) or a mild cleansing agent.

When cleaning the touchscreen display, use only a moist cloth. Do not use any cleaners; they may damage the surface of the touchscreen.

Daily Cleaning

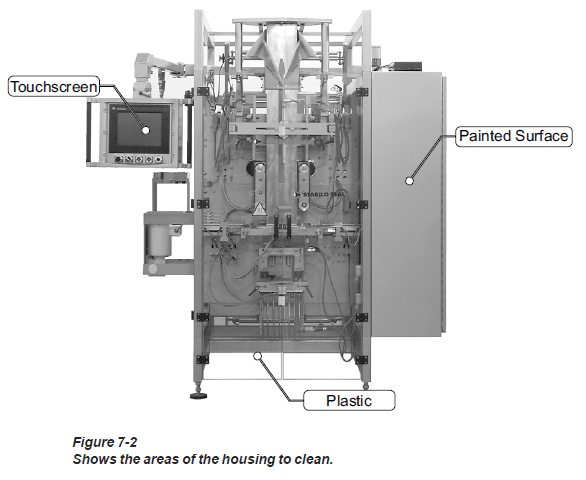

Sealing Surfaces Film residue will buildup on the sealing surfaces; especially when using printed film. Excessive buildup will make it more difficult to create good seals. To remove the residue, use a brass bristle brush to scrub it away. The sealing surfaces are on the faces of the horizontal sealing jaws and the vertical sealing bar. If your machine is equipped with a zipper applicator and/or a Stabilo Seal® Sealing System, you will also need to scrub the zipper tacking bar, the zipper sealing jaws, and the stabilo sealing jaws. This should be done just after the machine is lock-out and tagged-out, while the sealing tools are still warm.

Danger: Be sure to wear appropriate protective gloves when working around the sealing tools. The gloves must protect your hands from the hot sealing jaws and from the shape serration of the cutting knife.

Figure 7.3

Shows the sealing tools to clean with a brass bristle brush.

Daily Cleaning

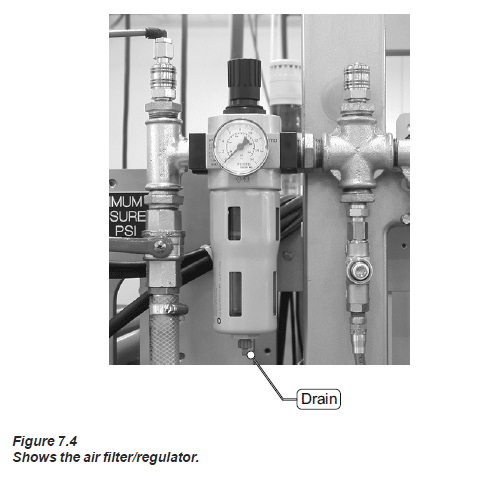

Air Filter/Regulator The air filter/regulator removes condensation from the air supply. Depending on the quality of your air supply, water can accumulate in the bowl of the regulator very quickly. Use the following procedure to drain the bowl.

To remove water from the bowl.

1. Enable the air supply to the air filter regulator.

2. Set the regulator pressure to about 5 psi.

3. Open the drain at the bottom of the regulator bowl.

4. When the bowl is empty, close the drain.

------------------------------------------------------------------------

More Rovema Support Options

See Additional Maintenance Articles

Looking for a manual for your Vertical Form Fill and Seal (VFFS) Bagger? Click here!